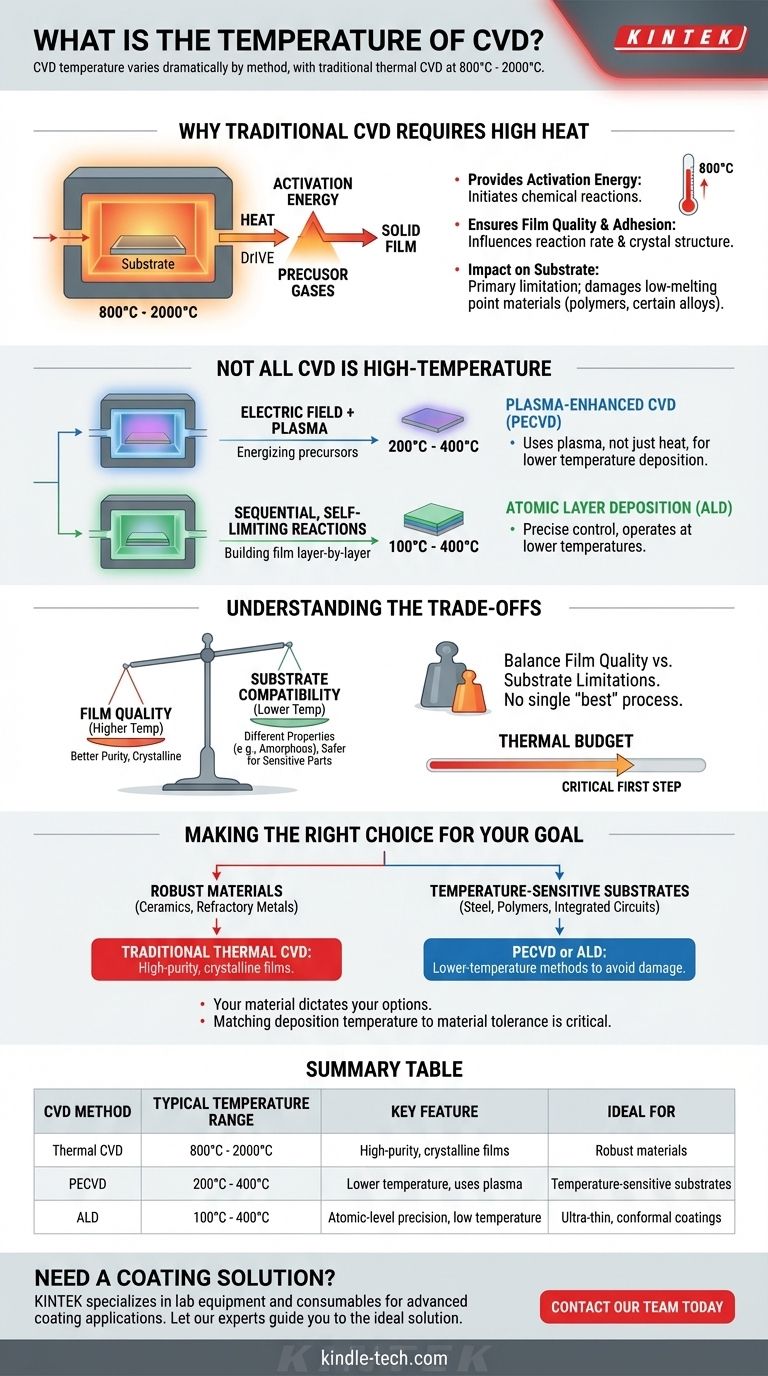

The temperature for Chemical Vapor Deposition (CVD) varies dramatically by method, but traditional thermal CVD operates at very high temperatures, typically in the range of 800°C to 2000°C. This intense heat is necessary to drive the chemical reactions that form the desired coating on a material's surface.

The central concept is not a single temperature for all CVD processes. Instead, the required temperature is a critical variable that distinguishes different CVD methods, with the choice depending entirely on the heat tolerance of the material being coated.

Why Traditional CVD Requires High Heat

The temperature of the substrate is one of the most critical parameters in the CVD process. In conventional thermal CVD, heat is the primary engine driving the entire deposition.

Providing the Activation Energy

For the precursor gases to react and form a solid film, they need a significant amount of energy. In thermal CVD, high temperature provides this "activation energy," initiating the chemical reactions directly on the substrate surface.

Ensuring Film Quality and Adhesion

Proper temperature control is essential for growing a high-quality, dense, and well-adhered coating. The temperature influences the reaction rate, crystal structure, and overall integrity of the deposited film.

The Impact on the Substrate

This high-temperature requirement is the primary limitation of thermal CVD. Temperatures often exceed 800°C, which is higher than the tempering temperature of many steels and far too high for materials with low melting points, such as polymers or certain alloys.

Not All CVD is High-Temperature

The limitations of thermal CVD led to the development of alternative methods that use other forms of energy to drive the reaction, allowing for significantly lower processing temperatures. "CVD" is a family of technologies, not a single process.

Plasma-Enhanced CVD (PECVD)

Instead of relying solely on heat, Plasma-Enhanced CVD (PECVD) uses an electric field to generate a plasma. This plasma energizes the precursor gases, allowing the deposition reaction to occur at much lower temperatures, often in the 200°C to 400°C range.

Atomic Layer Deposition (ALD)

While a distinct process, Atomic Layer Deposition (ALD) is often considered a subtype of CVD. It uses sequential, self-limiting reactions to build a film one atomic layer at a time. This precise control allows it to operate at lower temperatures than traditional CVD.

Understanding the Trade-offs

Choosing a CVD method involves balancing the need for film quality against the limitations of the substrate material. There is no single "best" process; there is only the best process for a specific application.

Temperature vs. Film Quality

Generally, higher deposition temperatures in thermal CVD lead to films with higher purity and better crystallinity. Lower-temperature processes like PECVD may result in films with different properties, such as being amorphous rather than crystalline, which can be either a benefit or a drawback depending on the goal.

Temperature vs. Substrate Compatibility

This is the most critical trade-off. The maximum allowable temperature of your substrate material will immediately rule out certain CVD methods. You cannot use 900°C thermal CVD to coat a plastic component that melts at 200°C.

Making the Right Choice for Your Goal

Your material dictates your options. The decision to use a specific CVD process is fundamentally a question of thermal budget.

- If your primary focus is coating robust, high-melting-point materials like ceramics or refractory metals: Traditional thermal CVD is often the ideal choice for achieving high-purity, crystalline films.

- If your primary focus is coating temperature-sensitive substrates like steel, polymers, or integrated circuits: You must use a lower-temperature method like PECVD to avoid damaging or destroying the part.

Ultimately, matching the deposition temperature to your material's tolerance is the critical first step for any successful coating application.

Summary Table:

| CVD Method | Typical Temperature Range | Key Feature | Ideal For |

|---|---|---|---|

| Thermal CVD | 800°C - 2000°C | High-purity, crystalline films | Robust materials (ceramics, metals) |

| PECVD | 200°C - 400°C | Lower temperature, uses plasma | Temperature-sensitive substrates (polymers, electronics) |

| ALD | 100°C - 400°C | Atomic-level precision, low temperature | Ultra-thin, conformal coatings |

Need a Coating Solution for Your Specific Material?

Choosing the right CVD process is critical to your project's success. The wrong temperature can damage your substrates or fail to achieve the desired film properties.

KINTEK specializes in lab equipment and consumables for advanced coating applications. We can help you select the perfect system—whether it's a high-temperature furnace for robust materials or a precise PECVD setup for delicate components—ensuring optimal film quality and substrate integrity.

Let our experts guide you to the ideal solution. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Graphite Vacuum Continuous Graphitization Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit