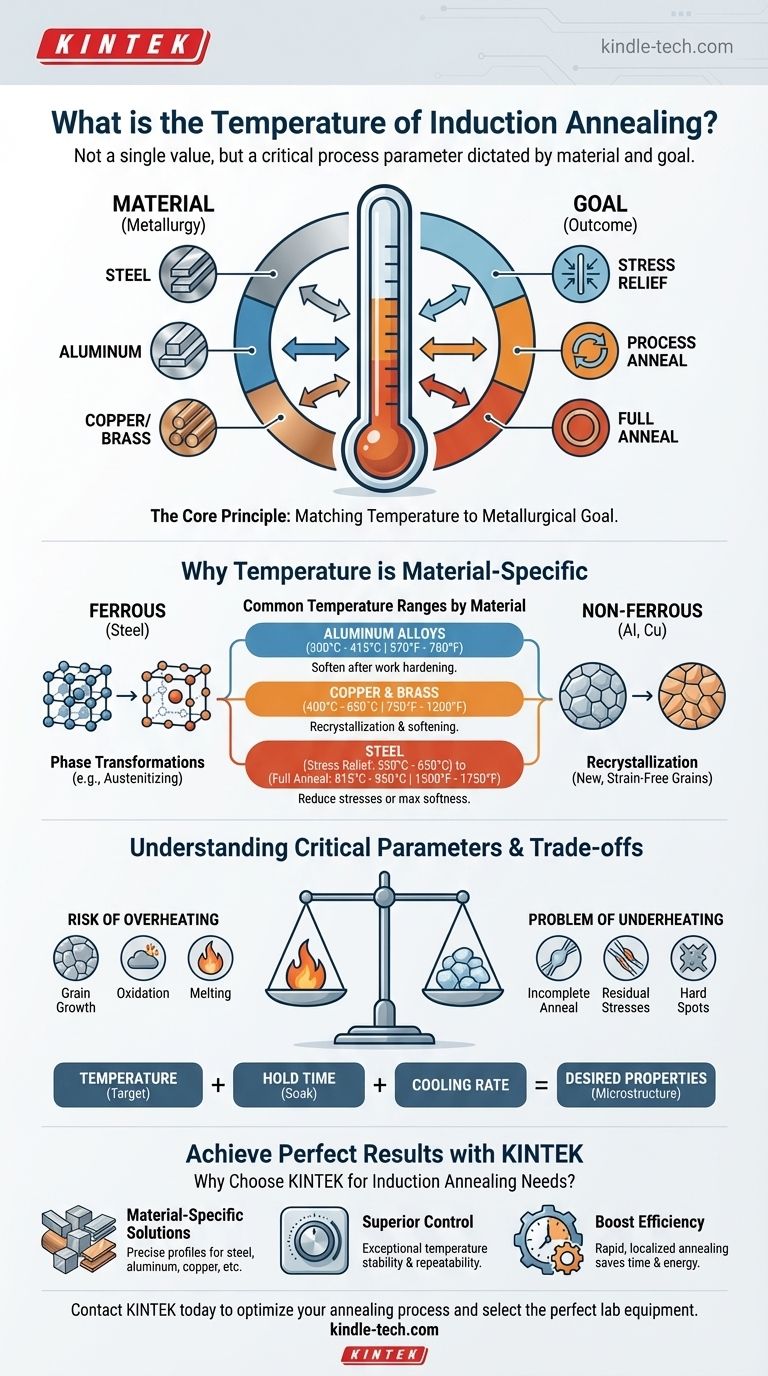

The temperature for induction annealing is not a single value. Instead, it is a critical process parameter that depends entirely on the specific metal being treated and the desired metallurgical outcome. For example, stress-relieving steel requires a different temperature than fully softening an aluminum alloy.

The core principle to understand is that induction annealing temperature is dictated by the material's unique metallurgy. The goal is to heat the metal to a precise point that triggers a specific change—like stress relief or recrystallization—without causing unwanted effects like excessive grain growth or melting.

The Core Principle: Matching Temperature to Metallurgical Goal

To control an annealing process, you must first understand the purpose of the heat treatment and how the chosen material responds to thermal energy.

What is Annealing?

Annealing is a heat treatment process that alters a material's microstructure to achieve a desired change in its mechanical or electrical properties.

Common goals include softening the metal to improve formability, increasing ductility, relieving internal stresses from prior work, and refining the grain structure.

Why Temperature is Material-Specific

Different metals and alloys have fundamentally different atomic structures and transformation points. The temperature required for annealing is directly tied to these metallurgical milestones.

For steels, the critical temperatures relate to phase transformations, such as changing from a ferrite-pearlite structure to austenite. For non-ferrous alloys like aluminum or copper, the key temperature is related to recrystallization, where new, strain-free grains form.

Common Temperature Ranges by Material

While specific temperatures must be validated for your exact alloy and goal, general guidelines provide a reliable starting point.

Annealing Steel

The temperature for annealing steel varies dramatically based on the carbon content and the intended outcome.

- Stress Relief: Typically 550°C to 650°C (1020°F to 1200°F). This reduces internal stresses with minimal effect on hardness.

- Process/Sub-critical Anneal: Typically 650°C to 720°C (1200°F to 1330°F). This is used to soften steel for further cold working.

- Full Anneal: Requires heating above the austenitizing temperature, usually 815°C to 950°C (1500°F to 1750°F), followed by very slow cooling to produce the softest possible state.

Annealing Copper and Brass

Copper and its alloys are annealed to soften them after work hardening. The process is governed by recrystallization.

The typical temperature range for annealing copper and brass is between 400°C and 650°C (750°F to 1200°F). Higher temperatures result in a faster and softer anneal but risk excessive grain growth.

Annealing Aluminum Alloys

Aluminum requires significantly lower temperatures and precise control to avoid overheating or melting.

Most aluminum alloys are annealed in the range of 300°C to 415°C (570°F to 780°F). The exact temperature and hold time are critical for achieving the desired properties without compromising the material's integrity.

Understanding the Trade-offs and Critical Parameters

Temperature is the most important variable, but it does not act alone. Failing to control the entire thermal profile can lead to process failure.

The Risk of Overheating

Exceeding the target temperature can be detrimental. It can cause excessive grain growth, which reduces strength and toughness, or unwanted surface oxidation. In extreme cases, it can lead to localized melting and scrapping the part.

The Problem of Underheating

Insufficient heat means the desired metallurgical transformation will not fully complete. This can result in an incomplete anneal, leaving residual stresses or hard spots that can cause failures in subsequent forming operations or in final service.

Why Hold Time and Cooling Rate Matter

Temperature is only one part of the thermal recipe.

- Hold Time: The material must be held at the target temperature long enough for the heat to penetrate the part and for the microstructure to fully transform. This is often called "soak time."

- Cooling Rate: After heating, the rate of cooling determines the final microstructure and properties. A slow cool is essential for a full anneal in steel, while other processes may be less sensitive.

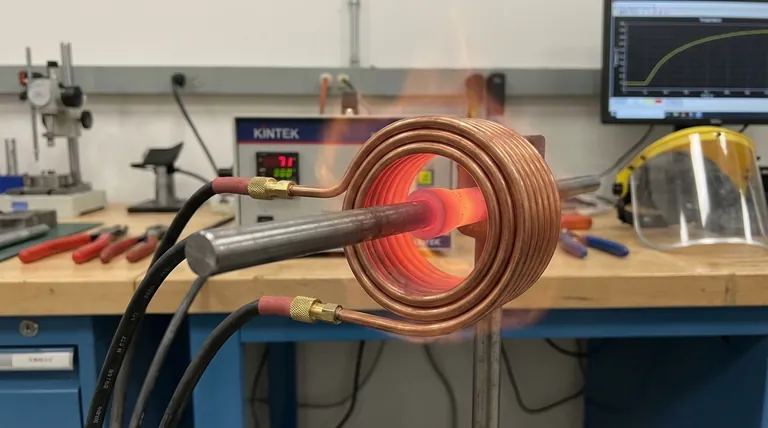

The Unique Advantage of Induction

Induction heating offers exceptionally precise, rapid, and repeatable temperature control. This allows for targeted annealing of specific zones on a part without affecting the rest of the component, a significant advantage over furnace-based methods.

Determining the Right Temperature for Your Application

To select the correct temperature, you must first define your objective. The process parameters are a direct function of the material properties you need to achieve.

- If your primary focus is maximum softness and ductility (Full Anneal): You must heat above the material's upper critical transformation temperature (e.g., austenitizing for steel) and cool it very slowly.

- If your primary focus is to relieve stress from manufacturing (Stress Relief): Use a lower, sub-critical temperature that is high enough to allow atomic movement but low enough to avoid significant microstructural change.

- If your primary focus is to soften a part for further cold working (Process Anneal): Heat to a temperature that allows for recrystallization without the time and energy cost of a full anneal.

- If you are working with non-ferrous alloys like aluminum or copper: Your temperatures will be significantly lower and are governed by recrystallization data for your specific alloy, not phase transformations.

Ultimately, mastering induction annealing comes from treating temperature not as a static number, but as a dynamic tool to control the final properties of your material.

Summary Table:

| Material | Common Annealing Temperature Range | Key Goal |

|---|---|---|

| Steel (Stress Relief) | 550°C - 650°C (1020°F - 1200°F) | Reduce internal stresses |

| Steel (Full Anneal) | 815°C - 950°C (1500°F - 1750°F) | Maximum softness & ductility |

| Aluminum Alloys | 300°C - 415°C (570°F - 780°F) | Soften after work hardening |

| Copper & Brass | 400°C - 650°C (750°F - 1200°F) | Recrystallization & softening |

Achieve Perfect Annealing Results with KINTEK

Selecting the right temperature is just the first step. Precise, repeatable heat control is what separates a successful anneal from a scrapped part. KINTEK's advanced induction heating systems provide the exact control you need for stress relief, softening, and full annealing of any metal.

Why choose KINTEK for your lab's induction annealing needs?

- Material-Specific Solutions: Our equipment is designed to handle the precise thermal profiles required for steel, aluminum, copper, and more.

- Superior Control: Avoid overheating and underheating with our systems' exceptional temperature stability and repeatability.

- Boost Efficiency: Achieve targeted, localized annealing faster than with traditional furnace methods, saving time and energy.

Ready to optimize your annealing process? Contact KINTEK today and let our experts help you select the perfect lab equipment for your specific material and application goals.

Visual Guide

Related Products

- Non Consumable Vacuum Arc Induction Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of a laboratory vacuum arc remelting furnace? Mastering High-Entropy Alloy Synthesis

- What are the different types of melting process? From Smelting to Suspension for Ultimate Purity

- What are the strengths of brazing? Achieve Strong, Clean, and Precise Metal Joining

- What is the difference between VAR and VIM? Legacy Vimscript Variables vs. Modern Neovim API

- How does vacuum arc melting equipment facilitate Ti-Cr-Al-Nb alloy prep? Precision High-Temp Melting Explained