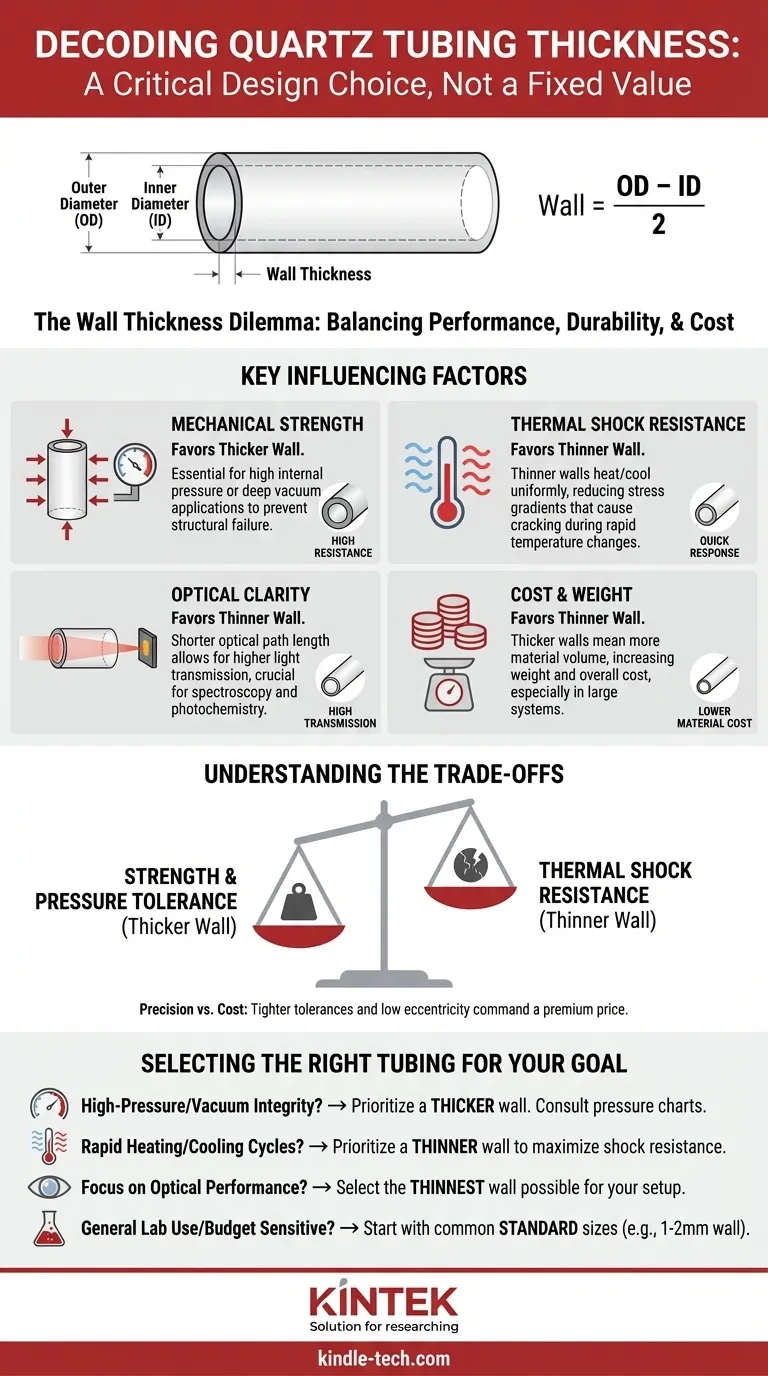

There is no single thickness for quartz tubing. Instead, wall thickness is a critical specification chosen from a wide range of standard and custom sizes. It is defined alongside the Outer Diameter (OD) and Inner Diameter (ID) to meet the precise demands of a scientific or industrial application.

The core takeaway is that wall thickness is not a fixed property but a fundamental design choice. Your selection must balance the competing requirements of mechanical strength, resistance to thermal shock, optical performance, and cost.

Why Wall Thickness is a Critical Specification

Quartz tubing is rarely selected by one dimension alone. The interplay between its diameters and wall thickness dictates its performance in any given environment.

The Relationship: OD, ID, and Wall

The three key dimensions are mathematically linked. The Outer Diameter (OD) is the total width of the tube, while the Inner Diameter (ID) is the size of the open bore.

Wall thickness is simply half of the difference between the OD and ID. A tube specified as 10mm OD with an 8mm ID will have a 1mm wall. Manufacturers' catalogs will typically list two of these three dimensions, allowing you to calculate the third.

Common Wall Thicknesses

While custom sizes are always possible, many applications use tubing with "standard" metric or imperial wall thicknesses.

Common values often include 1.0mm, 1.5mm, 2.0mm, and 3.0mm. However, this is highly dependent on the tube's overall diameter. Large-diameter furnace tubes may have walls 5mm thick or more, while fine capillary tubing walls can be a fraction of a millimeter.

Key Factors Influencing Your Choice

Choosing the correct wall thickness is an engineering decision. You must consider the specific stresses your application will place on the material.

Mechanical Strength and Pressure Rating

This is the most intuitive factor. A thicker wall provides greater mechanical strength.

This is critical for applications involving either high internal pressure or a deep vacuum. In both cases, a significant pressure differential exists across the tube wall, and a thicker wall is necessary to prevent structural failure.

Thermal Shock Resistance

This is a key, and often misunderstood, property of quartz. While quartz has excellent thermal stability, it can be fractured by rapid temperature changes, known as thermal shock.

Counterintuitively, a thinner wall often provides superior resistance to thermal shock. A thinner wall heats and cools more uniformly, reducing the internal stress gradients that cause cracking. A thick-walled tube heated quickly will have a very hot exterior and a cooler interior, creating immense stress.

Optical Clarity and Path Length

For applications like spectroscopy, photochemistry, or sight glasses, the optical properties of quartz are paramount.

The wall thickness directly determines the optical path length through the material. A thinner wall will generally allow for higher light transmission, which can be critical for sensitive measurements. However, this must be balanced against the need for sufficient rigidity and strength.

Weight and Material Cost

The simplest factor is often a practical one. Wall thickness is directly proportional to the volume of material used.

A thicker wall means a heavier and more expensive tube. For large or complex systems, this can have a significant impact on both the budget and the design of supporting structures.

Understanding the Trade-offs

Selecting a wall thickness is rarely a simple choice. You must navigate a series of compromises to find the optimal solution for your specific goal.

Strength vs. Thermal Performance

This is the most common trade-off. The need for high pressure tolerance (requiring a thick wall) is in direct conflict with the need for high thermal shock resistance (favoring a thin wall). You must identify which of these two factors is the dominant risk in your process.

Precision vs. Cost

Standard tubing has a tolerance on its wall thickness, meaning it can vary slightly around the circumference. This variation is called eccentricity.

For applications requiring perfectly uniform heating or precise flow dynamics, tubing with very low eccentricity and tight wall tolerance is available. This high-precision material comes at a significantly higher cost than standard-grade tubing.

Standard vs. Custom Tubing

Manufacturers offer a wide array of standard sizes that are readily available and cost-effective. These are suitable for the vast majority of applications.

If your project has unique constraints that cannot be met by a standard size, you can order custom-drawn tubing. Be prepared for a higher price and a much longer lead time.

Selecting the Right Tubing for Your Application

Answering "what thickness do I need?" begins by defining your primary objective.

- If your primary focus is high-pressure or vacuum integrity: Prioritize a thicker wall and consult supplier-provided pressure charts for your chosen OD.

- If your primary focus is rapid heating and cooling cycles: Prioritize a thinner wall to maximize thermal shock resistance and prevent cracking.

- If your primary focus is optical performance: Select the thinnest wall possible that still provides the necessary mechanical stability for your setup.

- If your primary focus is general lab use or cost-sensitive prototyping: Begin with common, inexpensive standard sizes (e.g., 1-2mm wall) and adapt only if necessary.

By understanding these core principles, you can confidently specify the precise quartz tubing that meets your technical requirements and budget.

Summary Table:

| Factor | Favors Thicker Wall | Favors Thinner Wall |

|---|---|---|

| Mechanical Strength | High pressure or vacuum applications | General use, low-pressure systems |

| Thermal Shock Resistance | - | Rapid heating/cooling cycles |

| Optical Clarity | - | Spectroscopy, photochemistry |

| Cost & Weight | - | Budget-sensitive projects |

Need help specifying the perfect quartz tubing for your application?

At KINTEK, we specialize in providing high-quality lab equipment and consumables, including a wide range of quartz tubing with standard and custom dimensions. Our experts can help you balance the critical factors of wall thickness, OD, and ID to ensure optimal performance, durability, and cost-efficiency for your specific laboratory needs.

Contact our team today for a consultation and let us help you find the ideal solution!

Visual Guide

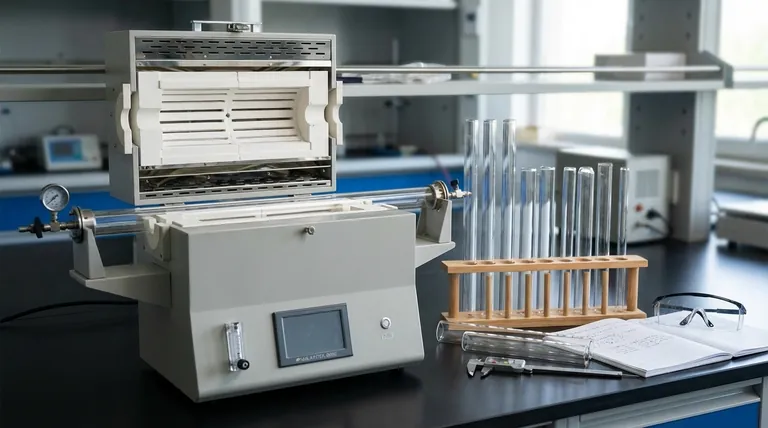

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing