In IR spectroscopy, potassium bromide (KBr) is used as a transparent matrix material to prepare solid samples for analysis. The solid sample is finely ground and mixed with KBr powder, which is then compressed under high pressure. This process forms a thin, transparent pellet that allows the infrared beam to pass through the sample, enabling its absorption spectrum to be measured.

The core challenge with solid samples is getting infrared light to pass through them without scattering. KBr solves this by acting as an inert, IR-transparent medium that holds the finely dispersed sample in the spectrometer's beam path.

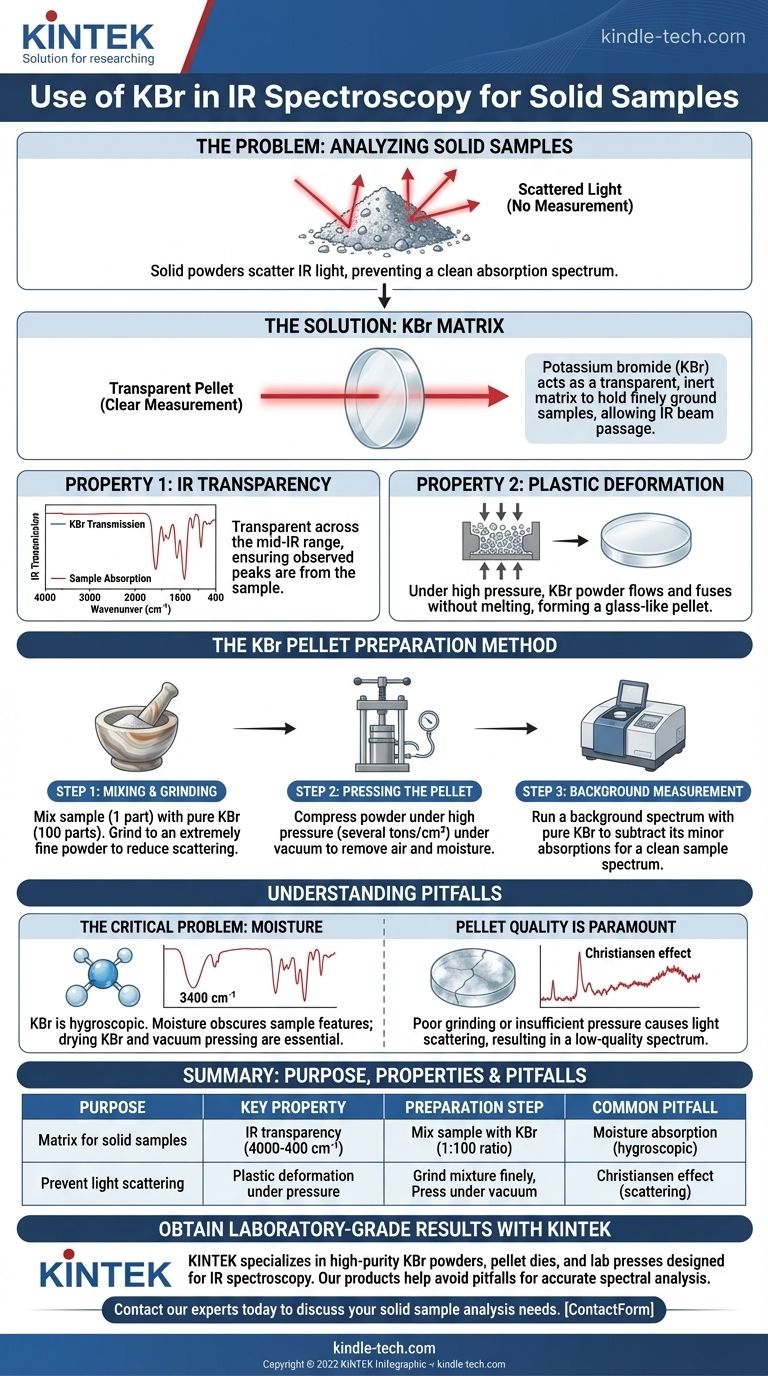

The fundamental Problem: Analyzing Solid Samples

Infrared (IR) spectroscopy works by passing a beam of infrared light through a sample and measuring which wavelengths are absorbed. For liquids and gases, this is straightforward.

However, shining an IR beam at a pile of solid powder doesn't work. The light would simply scatter off the surfaces of the particles, preventing a clean measurement of absorption. We need a way to hold the solid sample in a form that is transparent to the IR beam.

Why KBr is the Ideal Solution

Potassium bromide is the most common material used for this purpose due to two essential physical properties.

Property 1: Infrared Transparency

The primary requirement for a matrix material is that it doesn't absorb IR light itself, at least not in the region of interest.

KBr is transparent across the vast majority of the mid-infrared range (4000-400 cm⁻¹). This ensures that any absorption peaks seen in the final spectrum are from the sample, not from the KBr holding it.

Property 2: Plastic Deformation

Alkali halides like KBr exhibit a unique property: under high pressure, they undergo plastic deformation.

The crystalline KBr powder flows and fuses together without melting, forming a solid, glass-like disc. This process effectively traps the finely ground sample particles within a solid, transparent window.

The KBr Pellet Preparation Method

Creating a high-quality KBr pellet requires a careful and methodical approach to ensure a clear, usable spectrum.

Step 1: Mixing and Grinding

The sample is mixed with a much larger amount of very pure, dry KBr powder. The typical ratio is about 1 part sample to 100 parts KBr.

This mixture must be ground to an extremely fine powder, often using an agate mortar and pestle. Proper grinding is critical to reduce light scattering and ensure the sample is uniformly dispersed.

Step 2: Pressing the Pellet

The fine powder mixture is placed into a die and compressed under very high pressure (several tons per square centimeter).

This is typically done under a vacuum. The vacuum helps remove trapped air and, crucially, any residual moisture from the powder, which could interfere with the spectrum.

Step 3: Background Measurement

Before analyzing the sample pellet, a background spectrum is often run. This can be done with an empty pellet holder or, ideally, with a pellet made from pure KBr.

This background scan allows the instrument's software to subtract any minor absorptions from the KBr itself or from atmospheric water vapor and CO₂, resulting in a clean spectrum of just the sample.

Understanding the Trade-offs and Pitfalls

While the KBr pellet method is a standard technique, it requires care to avoid common problems that can ruin an analysis.

The Critical Problem of Moisture

Potassium bromide is hygroscopic, meaning it readily absorbs water from the atmosphere.

Water has a very strong, broad absorption band in the IR spectrum (around 3400 cm⁻¹). If the KBr or sample is not perfectly dry, this water peak can obscure important features of the sample's spectrum. This is why drying the KBr and using a vacuum press is so important.

Pellet Quality is Paramount

A poorly made pellet can lead to unusable results.

If the sample is not ground finely enough, light scattering (known as the Christiansen effect) can distort the baseline of the spectrum. If the pellet is cracked or opaque due to insufficient pressure or trapped air, very little light will pass through, resulting in a noisy, low-quality spectrum.

When to Use the KBr Pellet Method

The KBr pellet is a powerful technique, but you must consider its requirements.

- If your primary focus is obtaining a high-quality, high-resolution spectrum of a stable solid: The KBr pellet method is the gold standard for transmission IR spectroscopy.

- If your sample is sensitive to moisture or high pressure: You must take extreme care to dry all components, or consider an alternative method like a Nujol mull.

- If you need a quick, qualitative analysis: Other methods like Attenuated Total Reflectance (ATR) may be faster and require less sample preparation.

By mastering the KBr pellet technique, you can reliably prepare solid samples to obtain clear and accurate infrared spectra.

Summary Table:

| Purpose | Key Property | Preparation Step | Common Pitfall |

|---|---|---|---|

| Matrix for solid samples | IR transparency (4000-400 cm⁻¹) | Mix sample with KBr (1:100 ratio) | Moisture absorption (hygroscopic) |

| Prevent light scattering | Plastic deformation under pressure | Grind mixture finely | Insufficient grinding/pressure |

| Enable transmission measurement | Forms transparent pellet | Press under vacuum | Christiansen effect (light scattering) |

Obtain laboratory-grade results with reliable sample preparation.

KINTEK specializes in high-purity KBr powders, pellet dies, and lab presses designed specifically for IR spectroscopy. Our products help you avoid common pitfalls like moisture contamination and ensure consistent, high-quality pellets for accurate spectral analysis.

Contact our experts today to discuss your solid sample analysis needs and discover the right equipment for your laboratory.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- kbr pellet press 2t

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is the physical mechanism for sintering Cu-Cr-Nb powders? Overcoming Oxide Barriers with Hydraulic Loading

- What is the purpose of the XRF test? Rapid, Non-Destructive Elemental Analysis

- How do you prepare pressed pellets for XRF? A Step-by-Step Guide to Reliable Sample Analysis

- Why is a laboratory hydraulic press used for cold pressing SiCp/2009Al composites? Enhance Green Body Quality

- What is the purpose of a laboratory hydraulic press in welding aerosol analysis? Create Clear Pellets for FTIR Success

- Why are hydraulic presses dangerous to operate? Uncover the Silent, Deceptive Risks

- What role does a laboratory hydraulic press play in platinum recovery research? Enhancing Sample Precision

- What are the applications of a hydraulic press? From Metal Shaping to Material Testing