At its core, a laboratory reactor is a highly controlled and contained vessel designed for running chemical or biological processes on a research and development scale. Its primary use is to provide a safe and precise environment where scientists can manipulate variables like temperature, pressure, and mixing to study reactions, synthesize new materials, or optimize industrial processes. For example, it might be used for synthesizing a new pharmaceutical compound under high pressure or for depositing a nanotechnology film onto a surface.

The true purpose of a lab reactor is not simply to hold a reaction, but to transform a chemical concept into a controllable, repeatable, and understandable process. It is the bridge between a theoretical formula on a whiteboard and a viable real-world application.

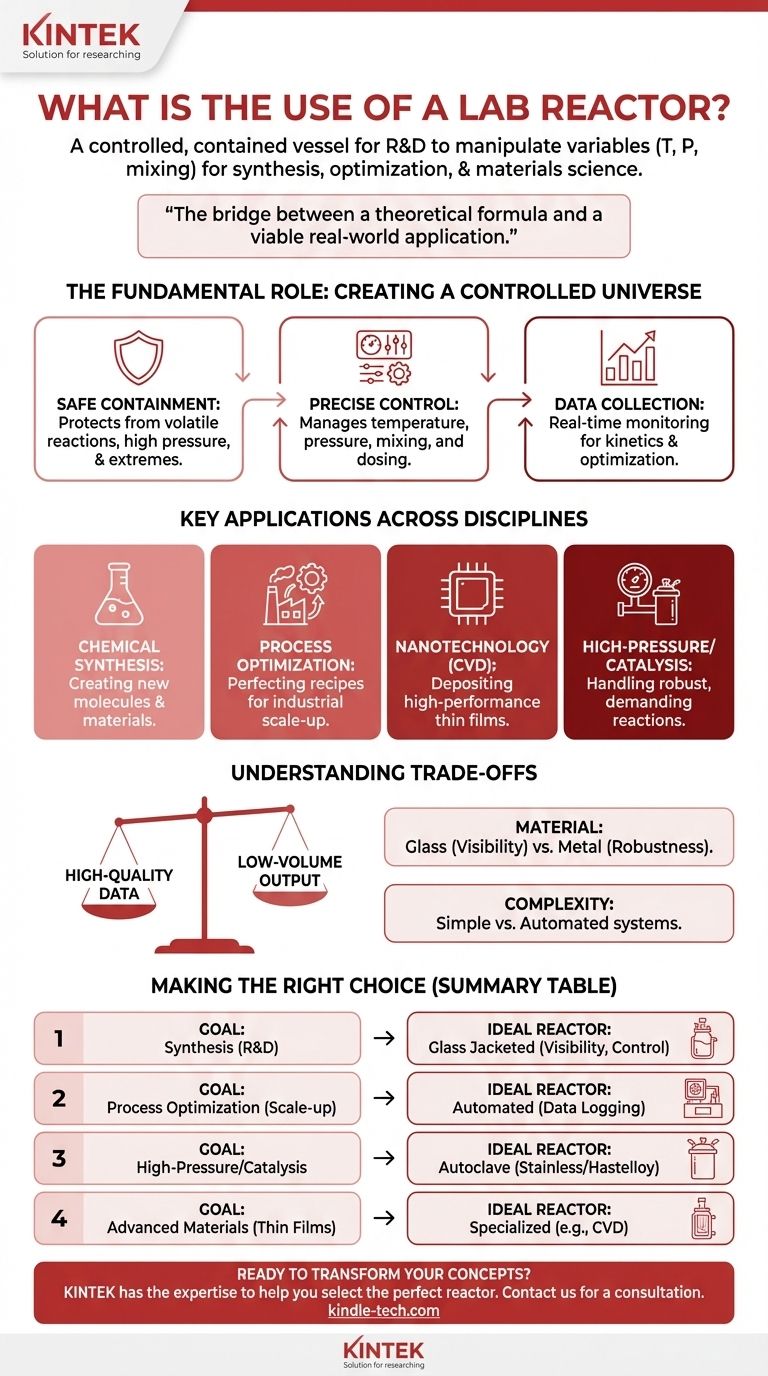

The Fundamental Role: Creating a Controlled Universe

A lab reactor's value comes from its ability to create a miniature, self-contained environment where every critical parameter can be meticulously managed and monitored. This control is what enables reproducible science.

Containing the Reaction

The most basic function of a reactor is safe containment. Many chemical reactions are volatile, involving high pressures, extreme temperatures, or hazardous materials.

A reactor, whether made of glass or robust metal alloys, is engineered to withstand these conditions, protecting both the researcher and the integrity of the experiment.

Precise Control of Variables

A simple beaker is a container; a reactor is a control system. It allows researchers to precisely dictate the conditions of the reaction.

This includes temperature control (via heating/cooling jackets), pressure management (using sealed systems and regulators), mixing speed, and the controlled addition of reactants over time. This level of control is impossible to achieve in standard laboratory glassware.

Enabling Data Collection and Analysis

Reactors are designed for observation and data gathering. They often include ports for probes to monitor pH, temperature, or pressure in real time.

This allows scientists to track the progress of a reaction, understand its kinetics (how fast it proceeds), and determine the optimal conditions for maximizing yield and purity.

Key Applications Across Scientific Disciplines

While the principle is universal, the specific use of a lab reactor varies widely depending on the scientific goal.

Chemical Synthesis

This is the most common application. Chemists use reactors to create new molecules, polymers, or materials by combining different chemical precursors under specific, controlled conditions.

Process Development and Optimization

Before a chemical process can be implemented in a large-scale factory, it must be perfected on a small scale. Lab reactors are used to find the most efficient, safe, and cost-effective way to run a reaction.

Engineers test different temperatures, pressures, and catalyst concentrations to develop a "recipe" that can be scaled up for industrial production.

Nanotechnology and Film Deposition

Specialized reactors are used for advanced materials science. For example, a Chemical Vapor Deposition (CVD) reactor is used to create ultra-pure, high-performance thin films.

In this process, gaseous chemicals react near a heated substrate (like a silicon wafer) inside a vacuum, depositing a solid layer of material one atom at a time.

Understanding the Trade-offs

A lab reactor is a powerful tool, but it's essential to understand its limitations and the considerations involved in choosing one.

Scale vs. Data Quality

Lab reactors are built for high-quality data, not high-volume output. Their purpose is to generate the precise information needed for discovery and scale-up, not to function as a miniature factory.

Material Compatibility

The reactor's material is a critical choice. Glass reactors offer excellent visibility but are limited in pressure and temperature. Stainless steel or Hastelloy reactors can handle extreme pressures and corrosive chemicals but are opaque. The right material must be chosen to avoid contamination or reactor failure.

Cost and Complexity

Simple, manually operated glass reactors can be relatively affordable. However, highly automated systems with advanced sensors, software control, and specialized capabilities represent a significant investment in both cost and training.

Making the Right Choice for Your Goal

The ideal lab reactor is dictated entirely by your research objective.

- If your primary focus is fundamental research and synthesis: A versatile glass jacketed reactor with good visibility and broad temperature control is often the best starting point.

- If your primary focus is process optimization for scale-up: A highly automated system with precise dosing pumps and extensive data logging capabilities is crucial for generating reliable industrial data.

- If your primary focus is high-pressure chemistry or catalysis: A high-pressure autoclave made from a robust alloy like stainless steel or Hastelloy is non-negotiable for safety and performance.

- If your primary focus is materials science and thin films: A specialized system like a Chemical Vapor Deposition (CVD) reactor is purpose-built for that application and will deliver the best results.

Ultimately, selecting the correct lab reactor empowers you to transform your chemical insights into reliable and reproducible results.

Summary Table:

| Key Function | Primary Application | Ideal Reactor Type |

|---|---|---|

| Safe Containment & Synthesis | Chemical R&D, New Molecule Creation | Glass Jacketed Reactor |

| Process Optimization | Scaling Up Industrial Processes | Automated Reactor with Data Logging |

| High-Pressure/Catalytic Reactions | Catalysis, High-Pressure Chemistry | High-Pressure Autoclave (e.g., Stainless Steel) |

| Advanced Materials Science | Thin Film Deposition (e.g., Nanotech) | Specialized System (e.g., CVD Reactor) |

Ready to Transform Your Chemical Concepts into Controllable, Repeatable Processes?

Choosing the right lab reactor is critical for achieving reliable and reproducible results in your research or development. Whether you are synthesizing new compounds, optimizing an industrial process, or working with advanced materials, KINTEK has the expertise and equipment to meet your specific laboratory needs.

Let KINTEK, your trusted partner in lab equipment, help you select the perfect reactor to empower your discoveries.

Contact our experts today for a personalized consultation and discover how our reactors can bridge the gap between your theoretical formulas and viable real-world applications.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- Why must a vacuum reactor be used when mixing conductive polymer dispersions? Prevent Voids & Ensure Dielectric Integrity

- What are the structural advantages of a dual-chamber stainless steel tubular reactor? Optimize Ethanol Steam Reforming

- What conditions does a hydrothermal reactor provide for CuO nanofilms? Master High-Pressure Synthesis

- Why is a high-pressure reactor required for coal gangue leaching? Unlock Efficient Mineral Activation Today

- Why Use a PTFE-Lined Autoclave for Mg-Li Coating Synthesis? Ensure Purity and Structural Integrity in Hydrothermal Prep

- How does an experimental high-pressure reactor enhance biochar from mushroom substrates via HTC?

- Why is a high-pressure catalytic reaction device necessary for the HDO of eugenol? Master Complex Chemical Transformations

- Why are high-pressure stainless steel laboratory reactors required for the hydrothermal liquefaction of waste tires?