In modern engineering and materials science, vapor deposition techniques are a foundational set of processes used to apply extremely thin, high-performance coatings to a surface, known as a substrate. These techniques all operate on a simple principle: a solid material is converted into a vapor, transported, and then condensed back into a solid film on the target object. The primary families of these techniques are Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD).

The fundamental difference between deposition techniques lies in how the source material is turned into a vapor. Physical Vapor Deposition (PVD) uses physical means like heat or ion bombardment to create the vapor, while Chemical Vapor Deposition (CVD) uses chemical reactions between precursor gases.

The Two Pillars of Vapor Deposition

To understand these techniques, it's best to start with the high-level distinction between the physical and chemical approaches. This choice dictates the equipment, process conditions, and the final properties of the film.

Physical Vapor Deposition (PVD): The "Physical Force" Approach

PVD encompasses methods where the material to be deposited is physically transformed into a vapor. This happens inside a high-vacuum chamber, which allows vapor particles to travel directly to the substrate without colliding with air molecules.

There are two dominant PVD methods: thermal evaporation and sputtering.

Thermal evaporation is like boiling a metal in a vacuum. The source material is heated until it vaporizes, and this vapor then travels and condenses onto the cooler substrate, forming a film.

Sputtering is more like a microscopic sandblaster. High-energy ions are fired at a solid "target" of the desired material. These collisions physically knock atoms off the target, which then deposit onto the substrate.

Chemical Vapor Deposition (CVD): The "Chemical Reaction" Approach

CVD is fundamentally different. Instead of physically vaporizing a solid, this method introduces one or more volatile precursor gases into a reaction chamber.

These gases decompose or react with each other on the heated substrate's surface, leaving behind a solid film of the desired material. The byproducts of the reaction are then pumped away. This method relies entirely on the dissociation of gaseous species to build the film.

A Deeper Look at PVD Techniques

Because PVD is so widely used, it's worth understanding the variations within its main categories. The choice often comes down to the required film properties and the material being deposited.

Thermal Evaporation Methods

The primary difference between thermal evaporation techniques is simply the heat source used.

- Resistive Thermal Evaporation: Uses a resistive heat source (like a hot filament) to heat and evaporate the material.

- Electron-Beam Evaporation: A focused beam of high-energy electrons heats and evaporates the source material with great precision.

- Inductive Heating: Radio frequency (RF) power is run through a coil, inducing eddy currents that heat a crucible containing the material.

Sputtering Methods

Sputtering techniques are valued for creating exceptionally dense and adherent films.

Ion beam sputtering is considered a best-in-class PVD technique. It offers extremely precise control over the film's properties, resulting in smooth, dense coatings that are critical for advanced applications like optics and electronics.

Understanding the Trade-offs

Choosing a deposition technique is a matter of balancing requirements for film quality, material compatibility, and substrate shape.

PVD: Line-of-Sight Precision

PVD is a "line-of-sight" process, meaning the vapor travels in a straight line from the source to the substrate.

This makes it ideal for coating flat surfaces with high purity and precision. However, it struggles to uniformly coat complex, three-dimensional shapes with undercuts or hidden surfaces.

CVD: Conformal Coating Capability

Because CVD uses gases that can flow around an object, its greatest strength is producing highly conformal coatings.

It can uniformly coat intricate and complex shapes, which is impossible with line-of-sight PVD. The trade-off is often higher process temperatures and more complex chemical handling.

Making the Right Choice for Your Goal

The applications for these films are vast, from increasing the lifespan of machining tools to creating the intricate layers in a microprocessor. Your specific goal will determine the best path forward.

- If your primary focus is depositing a pure metal or alloy onto a relatively flat surface with high precision: PVD techniques like sputtering or e-beam evaporation are the superior choice.

- If your primary focus is uniformly coating a complex 3D object or creating a film from a specific chemical compound: CVD is almost always the required approach.

- If your primary focus is achieving the highest possible film density, purity, and smoothness for sensitive applications: Advanced PVD methods like ion beam sputtering offer unparalleled control.

Understanding this fundamental physical-versus-chemical distinction is the key to selecting the right tool for any advanced material challenge.

Summary Table:

| Technique | Principle | Key Advantage | Ideal For |

|---|---|---|---|

| PVD (Physical) | Physical vaporization of solid material | High purity, precise control | Flat surfaces, pure metals/alloys |

| CVD (Chemical) | Chemical reaction of precursor gases | Uniform coating of complex 3D shapes | Intricate parts, compound films |

Need expert guidance on selecting the right deposition technique for your application? KINTEK specializes in lab equipment and consumables for vapor deposition processes. Our team can help you choose the ideal PVD or CVD solution to achieve superior film quality, improve coating performance, and accelerate your materials research. Contact us today to discuss your specific requirements!

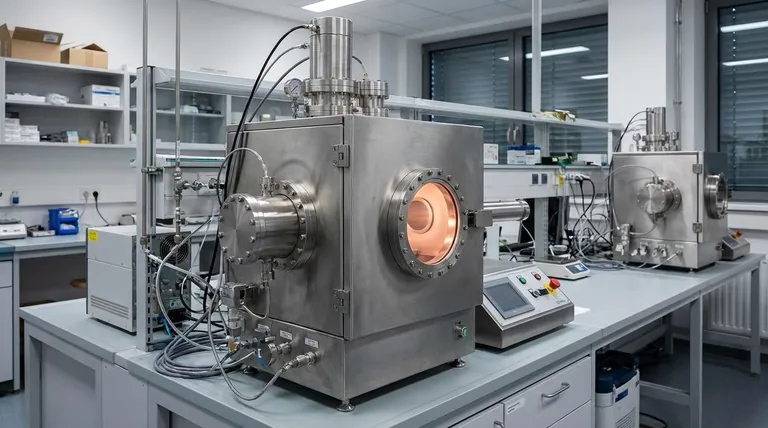

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application