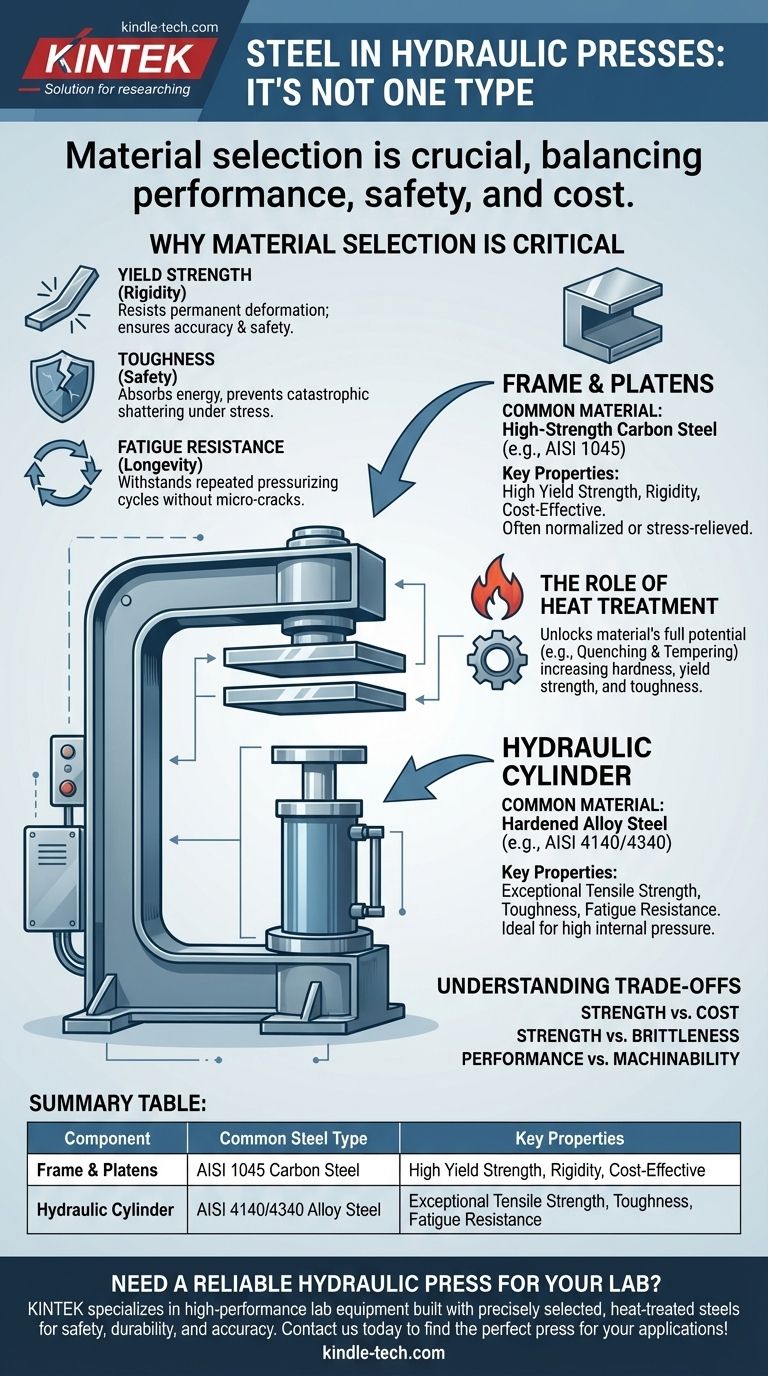

To be clear, there is no single type of steel used for all hydraulic presses. The specific material is carefully selected based on the component's function and the immense pressures it must withstand, with manufacturers typically using high-strength carbon steels for the frame and more robust alloy steels for critical components like the hydraulic cylinder. The goal is to use a material that resists permanent deformation and ensures operational safety under extreme force.

The critical factor is not a specific steel name, but its properties: high yield strength to prevent bending and high toughness to prevent shattering. The selection is a precise engineering choice balancing performance, safety, and cost for each part of the machine.

Why Material Selection is Critical

A hydraulic press operates on a simple principle: multiplying force. This means that its structural components, particularly the frame and cylinder, are subjected to incredible stress. Choosing the wrong material would lead to immediate failure.

Resisting Permanent Deformation (Yield Strength)

The frame and platens (the pressing surfaces) must be completely rigid. Any permanent bending would compromise the machine's accuracy and safety.

This is why yield strength is the most important property for the frame. It's the maximum stress a material can endure before it begins to deform permanently. The steel used must have a yield strength well above the press's maximum operational pressure.

Preventing Catastrophic Failure (Toughness)

Beyond just bending, you must prevent the steel from shattering. Toughness is a material's ability to absorb energy and deform slightly under stress without fracturing.

A brittle material might seem strong, but it could fail suddenly and catastrophically. A tough material will provide a margin of safety, potentially showing signs of stress before a complete failure occurs.

Withstanding Repetitive Use (Fatigue Resistance)

A press is used thousands of times over its lifespan. Each cycle of pressurizing and depressurizing is a stress cycle on the metal.

The chosen steel must have high fatigue resistance to withstand this repeated loading without developing micro-cracks that could lead to failure over time.

Common Materials in Hydraulic Press Construction

While specifications vary, certain classes of steel are consistently used for their proven performance in these high-stress environments.

For the Frame and Platens: High-Strength Carbon Steel

The largest part of the press is its C-frame or H-frame. For this, engineers often select a medium-to-high carbon steel, such as AISI 1045 or similar grades.

These steels offer an excellent balance of high strength and moderate cost. They are often normalized or stress-relieved to ensure a uniform internal structure and maximum durability. Some very large press frames may also be made from high-strength cast steel or ductile iron.

For the Hydraulic Cylinder: Hardened Alloy Steel

The hydraulic cylinder is the heart of the press and endures the highest internal pressure. This component demands a higher-performance material.

Chromium-molybdenum (ChroMoly) alloy steels like AISI 4140 or 4340 are common choices. These alloys, when properly heat-treated, achieve exceptional tensile strength and toughness, making them ideal for containing high-pressure hydraulic fluid.

The Role of Heat Treatment

Simply choosing the right steel is not enough. Heat treatment is a critical process that unlocks the material's full potential.

Processes like quenching and tempering rearrange the steel's molecular structure to dramatically increase its hardness, yield strength, and toughness. This is why a component made from heat-treated 4140 alloy steel is vastly superior to the same steel in its raw, untreated state.

Understanding the Trade-offs

The choice of steel is always an engineering compromise. Understanding these balances is key to appreciating why a press is built the way it is.

Strength vs. Cost

Alloy steels like 4140 are significantly more expensive than carbon steels like 1045. This is why they are used strategically for high-stress components like the cylinder, while the larger, less-stressed frame can be built from more economical carbon steel.

Strength vs. Brittleness

Increasing a steel's hardness (strength) can sometimes increase its brittleness. The engineering and heat treatment process must be precise to create a material that is both extremely strong and tough enough to resist fracture. This is a delicate and critical balance.

Performance vs. Machinability

Ultra-high-strength steels are often more difficult and time-consuming to machine, weld, and finish. This adds to the manufacturing cost. The material selection must account for the total cost of production, not just the raw material price.

Making the Right Choice for Your Goal

Your focus determines what you should look for in the material specifications.

- If your primary focus is purchasing a reliable press: Look for manufacturers who specify the use of high-strength, heat-treated carbon or alloy steels and name reputable hydraulic system suppliers (e.g., Bosch Rexroth), as this indicates a commitment to quality components.

- If your primary focus is designing or repairing a press: Your priority is to analyze the specific stress points. Use alloy steels like 4140 for critical, high-pressure components like the cylinder and piston, and select a suitable high-tensile carbon steel for the main frame structure based on force calculations.

Ultimately, the integrity of a hydraulic press is determined by the intelligent selection and treatment of steel to master immense force safely and repeatedly.

Summary Table:

| Component | Common Steel Type | Key Properties |

|---|---|---|

| Frame & Platens | AISI 1045 Carbon Steel | High Yield Strength, Rigidity, Cost-Effective |

| Hydraulic Cylinder | AISI 4140/4340 Alloy Steel | Exceptional Tensile Strength, Toughness, Fatigue Resistance |

Need a reliable hydraulic press for your lab? KINTEK specializes in high-performance lab equipment, including hydraulic presses built with precisely selected, heat-treated steels to ensure safety, durability, and accuracy under extreme force. Our expertise in material science means you get a machine engineered for longevity and precision. Contact us today to discuss your laboratory needs and find the perfect press for your applications!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What is the XRF method of preparation? Ensure Accurate Elemental Analysis with Proper Sample Prep

- Why use a laboratory hydraulic press for metal powders? Achieve High-Density Green Bodies for Hot Pressing

- What role does mechanical pressing play in recycled graphite electrodes? Optimize Density and Performance

- Why is a laboratory hydraulic press critical for sample preparation? Ensure Precision in Ion Beam Irradiation

- Why KBr is used for IR spectroscopy? The Ideal Medium for Solid Sample Analysis

- How do you prepare a sample for fluorescence spectroscopy? A Step-by-Step Guide for Accurate Results

- Why is pressing force important in sintering? Achieve Denser, Stronger Materials Faster

- What products are made by press forging? High-Strength Components for Aerospace, Automotive & Energy