To be precise, there is no single machine used to make lab-grown diamonds. Instead, they are created through two primary technological processes, each using highly specialized equipment: High Pressure/High Temperature (HPHT) and Chemical Vapor Deposition (CVD). These methods create diamonds that are chemically, physically, and optically identical to those mined from the earth.

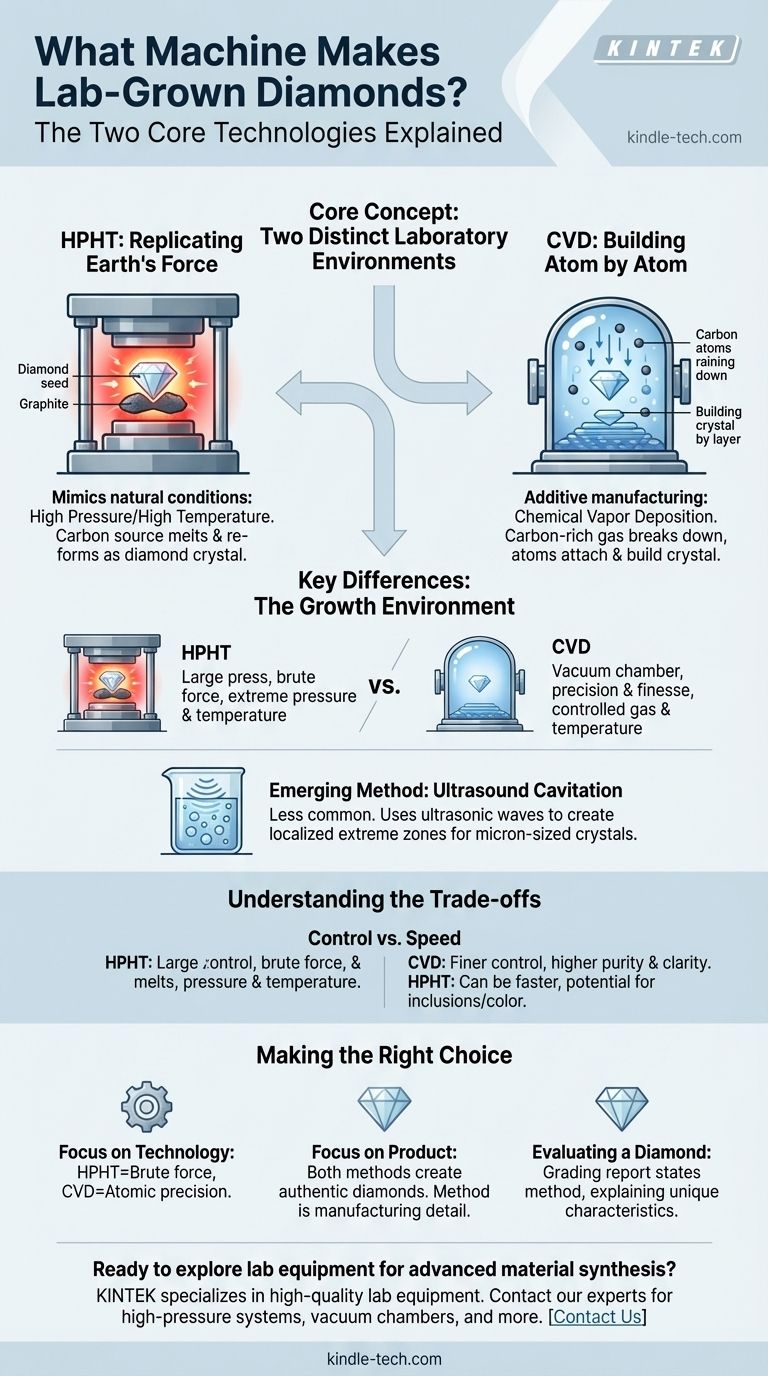

The core concept isn't about a specific "diamond-making machine" but about two distinct laboratory environments. One replicates the brute force of the Earth's mantle, while the other meticulously builds a diamond atom by atom.

The Two Primary Diamond-Growing Technologies

Understanding the creation of lab-grown diamonds means understanding the two foundational methods. Both begin with a tiny, pre-existing diamond sliver known as a "seed."

HPHT: Replicating the Earth's Force

The High Pressure/High Temperature (HPHT) method directly mimics the natural conditions under which diamonds form deep within the Earth.

A carbon source, like graphite, is placed in a large mechanical press along with the diamond seed. This press subjects the carbon to immense pressure and extremely high temperatures.

This intense environment causes the carbon source to melt and re-form as a diamond crystal, building upon the original seed.

CVD: Building Diamonds Atom by Atom

Chemical Vapor Deposition (CVD) is a fundamentally different approach, more akin to an additive manufacturing process.

The diamond seed is placed inside a sealed vacuum chamber. The chamber is then filled with a mixture of carbon-rich hydrocarbon gases.

These gases are heated, causing them to break apart and allowing carbon atoms to "rain down" and attach to the diamond seed, building up the crystal layer by layer. This method allows for a high degree of control over the diamond's final properties.

Key Differences in the Process

While both HPHT and CVD produce real diamonds, the equipment and environments are completely distinct.

The Growth Environment

HPHT relies on a powerful press to create a small, high-pressure, high-temperature environment. The equipment is designed for immense force.

CVD uses a lower-pressure vacuum chamber where the environment is controlled by managing gas composition and temperature. The equipment is designed for precision and finesse.

An Emerging Method: Ultrasound Cavitation

A third, less common method involves using ultrasonic cavitation. In this process, a suspension of graphite in an organic liquid is exposed to powerful ultrasonic waves.

This creates tiny bubbles that collapse violently, generating localized zones of extreme temperature and pressure that can convert the graphite into micron-sized diamond crystals at room temperature.

Understanding the Trade-offs

The choice between HPHT and CVD is driven by a balance of cost, desired outcome, and production efficiency. Each method presents a different set of advantages and challenges.

Control vs. Speed

The CVD process generally offers finer control over the diamond's chemical purity and ultimate clarity. The layer-by-layer growth allows for precise management of the process.

The HPHT process can sometimes be faster but may introduce different types of inclusions or color characteristics depending on the specific setup and materials used.

The Resulting Diamond

Historically, the growth method left subtle clues in the final diamond. However, advancements in both technologies have made it increasingly difficult to distinguish between them without specialized gemological equipment.

Both methods are capable of producing flawless, high-quality gemstones that are indistinguishable from natural diamonds to the naked eye.

Making the Right Choice for Your Goal

Whether you are studying, buying, or simply curious about lab-grown diamonds, understanding the origin technology provides crucial context.

- If your primary focus is on the technology: Understand that HPHT mimics nature with brute force, while CVD builds a diamond with atomic precision from a gas.

- If your primary focus is on the final product: Recognize that both methods produce authentic diamonds, and the choice of method is a manufacturing detail, not an indicator of the final quality.

- If you are evaluating a specific diamond: Review its grading report, as it will often state whether it was created via HPHT or CVD, helping to explain its unique crystal characteristics.

Ultimately, these advanced technologies simply offer a different path to the same extraordinary material.

Summary Table:

| Method | Core Process | Key Equipment |

|---|---|---|

| HPHT | Replicates Earth's mantle conditions | Large mechanical press for high pressure & temperature |

| CVD | Builds diamond atom by atom from gas | Sealed vacuum chamber for precise gas & temperature control |

| Ultrasound Cavitation | Uses sound waves to create extreme conditions | Ultrasonic reactor (less common, for micron-sized crystals) |

Ready to explore lab equipment for advanced material synthesis? KINTEK specializes in providing high-quality laboratory equipment and consumables. Whether your research involves high-pressure systems, vacuum chambers, or precision heating, our solutions are designed to meet the rigorous demands of modern labs. Contact our experts today to find the perfect equipment for your diamond growth or other material science projects!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- CVD Diamond Domes for Industrial and Scientific Applications

People Also Ask

- What is the difference between MPCVD and HFCVD? Choose the Right CVD Method for Your Application

- Which lab grown diamond process is best? Focus on Quality, Not the Method

- How to start a lab grown diamond business? Choose the Right Model for Success

- What is a microwave plasma reactor? Unlock Precision Synthesis of High-Performance Materials

- How does microwave plasma work? Unlock Precision Material Synthesis for Advanced Manufacturing