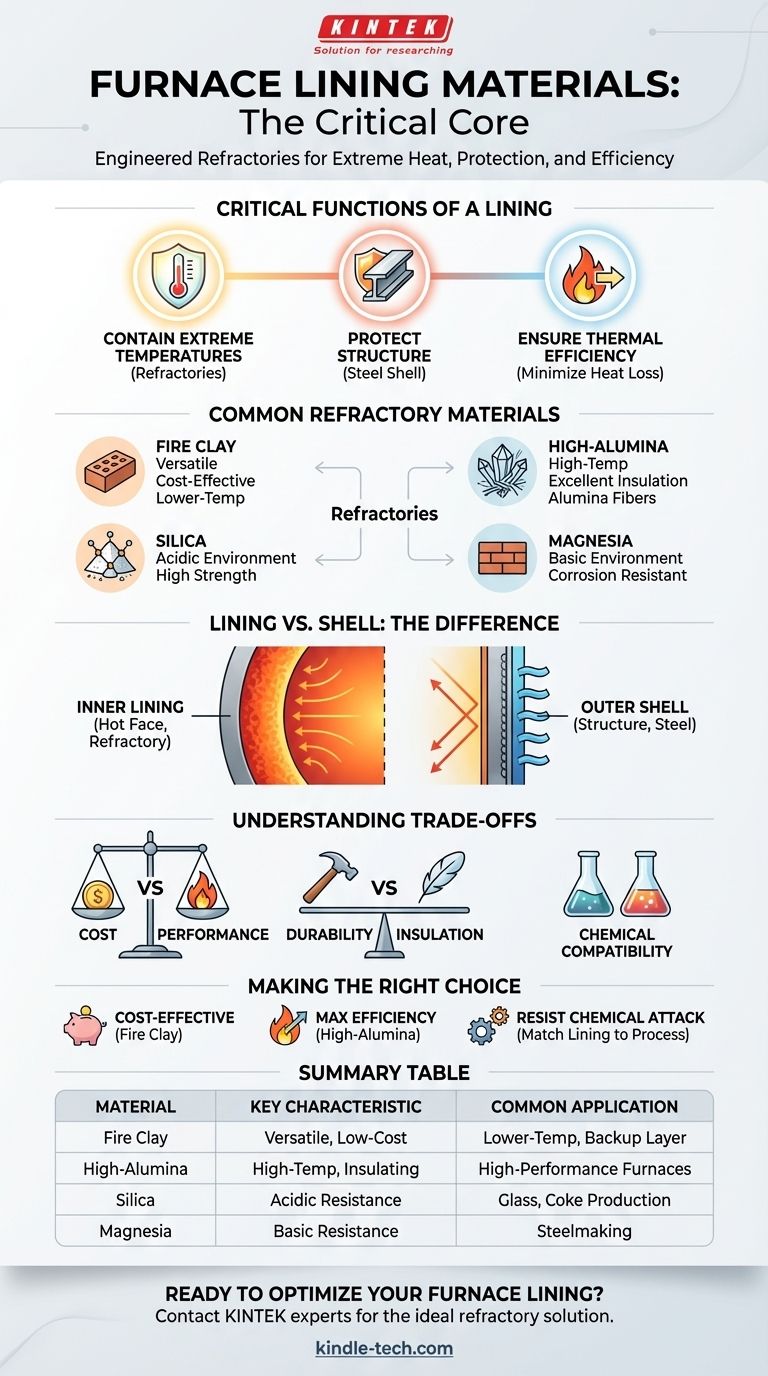

In short, furnace linings are made from specialized, heat-resistant materials known as refractories. The most common types are fire clay, high-alumina materials (including alumina fibers), silica, and magnesia. The specific material chosen is dictated by the furnace's maximum operating temperature, the chemical environment within it, and the need for thermal efficiency.

The critical takeaway is that a furnace lining is not a single material but a carefully engineered system. It is designed to contain extreme heat, protect the furnace's outer steel structure, and minimize energy loss, with the material choice depending entirely on the specific application.

Why a Specialized Lining is Critical

A furnace's lining is its most essential component for safe and efficient operation. It serves as the primary barrier between the intense internal heat and the external environment, performing three vital functions.

Containing Extreme Temperatures

The primary role of the lining is to withstand the furnace's operating temperature without melting, cracking, or degrading. These materials, known as refractories, are designed for exceptional thermal stability.

Protecting the Furnace Structure

The outer shell of a furnace is typically made of welded carbon steel or stainless steel. This structure provides mechanical strength but would quickly deform and fail if exposed to internal process temperatures. The refractory lining acts as a thermal shield, keeping the shell at a safe temperature.

Ensuring Thermal Efficiency

A good lining minimizes heat loss to the outside. Materials with low thermal conductivity and low heat storage, like alumina fibers, prevent energy from escaping, which reduces fuel consumption and improves the furnace's overall performance.

Common Refractory Materials Explained

While many refractories exist, a few key types form the backbone of most industrial furnace linings.

Fire Clay

Fire clay is a foundational refractory made from clay minerals. It is highly versatile and cost-effective, making it a common choice for lining lower-temperature furnaces or as a backup layer behind more advanced materials.

High-Alumina Materials

As the name suggests, these refractories have a high concentration of aluminum oxide (alumina). The higher the alumina purity, the higher the temperature it can withstand. This category includes dense bricks, castables, and lightweight insulation like high-purity alumina fiber boards, which offer excellent heat resistance and insulation.

Silica

Silica bricks are used in furnaces that handle acidic materials (like in some glass and coke manufacturing). They have excellent strength at high temperatures but must be heated and cooled carefully to prevent cracking.

Magnesia

Conversely, magnesia (magnesium oxide) is a basic refractory used in furnaces that process basic materials, such as in steelmaking. It is chosen for its ability to resist corrosion from basic slags and environments.

The Difference Between Lining and Shell

It is crucial to distinguish between the internal lining and the external shell, as they are made of different materials and serve entirely different purposes.

The Inner Lining (The Hot Face)

This is the layer directly exposed to the heat and process environment. It is always made of a refractory material (like fire clay or alumina) selected for its thermal and chemical resistance.

The Outer Shell (The Structure)

This is the furnace's external framework, typically made of welded steel plate. Its function is purely structural. It is often equipped with water or air cooling systems to prevent heat-related deformation, relying entirely on the inner lining for thermal protection.

Understanding the Trade-offs

Selecting a lining material is a matter of balancing competing priorities.

Cost vs. Performance

High-purity alumina refractories offer superior temperature resistance and insulation but come at a significantly higher cost than standard fire clay. The choice depends on whether the operational demands justify the investment.

Durability vs. Insulation

Dense refractory bricks are extremely durable and resist physical wear and chemical attack. However, lightweight materials like ceramic fiber boards are far better insulators. Many furnaces use a composite lining: a dense "hot face" layer for durability backed by a fiber layer for insulation.

Chemical Compatibility

Using a chemically incompatible refractory can lead to catastrophic failure. For example, placing a silica (acidic) brick in contact with a basic slag will cause it to corrode and dissolve rapidly. The lining chemistry must match the process chemistry.

Making the Right Choice for Your Furnace

Your final decision should be guided by your primary operational goal.

- If your primary focus is cost-effectiveness in lower-temperature applications: Fire clay is the most reliable and economical choice.

- If your primary focus is maximum thermal efficiency and high-temperature performance: High-purity alumina, especially in fiber or board form, provides the best insulation and heat resistance.

- If your primary focus is resisting chemical attack from the process: You must match the lining's chemistry (e.g., silica for acidic, magnesia for basic) to your specific environment to ensure longevity.

Selecting the correct furnace lining is a strategic decision that directly impacts safety, efficiency, and operational longevity.

Summary Table:

| Material | Key Characteristics | Common Applications |

|---|---|---|

| Fire Clay | Cost-effective, versatile | Lower-temperature furnaces, backup layer |

| High-Alumina | High temperature resistance, excellent insulation | High-performance furnaces, thermal efficiency |

| Silica | Excellent strength, acidic environment resistance | Glass manufacturing, coke production |

| Magnesia | Basic environment resistance | Steelmaking furnaces |

Ready to Optimize Your Furnace Lining?

Choosing the right refractory material is critical for the safety, efficiency, and longevity of your laboratory or industrial furnace. KINTEK specializes in providing high-quality lab equipment and consumables, including the precise furnace linings your operations demand.

Our experts can help you select the ideal material—whether cost-effective fire clay or high-performance alumina fiber—to match your specific temperature, chemical, and insulation needs.

Contact us today to discuss your furnace requirements and discover how our solutions can enhance your lab's performance.

Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Graphite Vacuum Continuous Graphitization Furnace

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What temperature is needed for pyrolysis waste? A Guide to Optimizing Your Waste-to-Value Process

- At what temperature is conventional pyrolysis done? Unlock the Right Temperature for Your Desired Product

- What are the factors affecting the yield of bio-oil from the pyrolysis of coconut shell? Control 4 Key Parameters

- What is the range of pyrolysis? Master Temperature Control for Optimal Bio-Product Yields

- What is the difference between pyrolysis combustion and gasification? A Guide to Thermal Conversion Technologies