The most suitable materials for hot zones in high-temperature vacuum and crystal growth furnaces fall into two primary categories: refractory metals, specifically molybdenum and tungsten, and carbon-based materials like high-purity graphite and carbon-carbon composites. The selection is not about which is universally "best," but which material's distinct properties best align with the specific process requirements, operating temperature, and desired level of purity.

Your fundamental decision is between a metallic hot zone (molybdenum/tungsten) and a graphite-based hot zone. Metallic zones excel in high-purity applications, while graphite zones offer superior thermal responsiveness for faster cycle times and often lower initial costs.

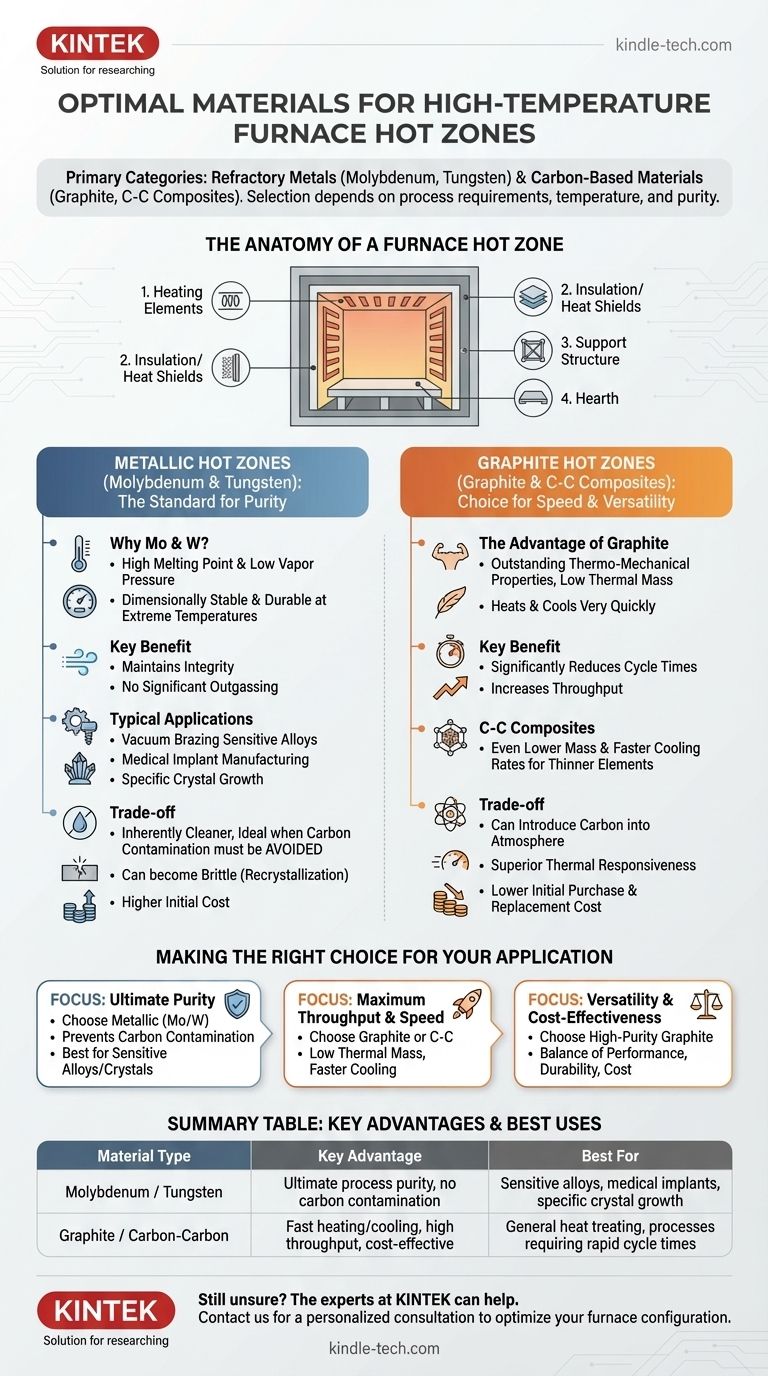

The Anatomy of a Furnace Hot Zone

Before comparing materials, it's crucial to understand what a "hot zone" entails. It is the functional core of the furnace, responsible for generating and containing extreme heat.

Key Components

A typical hot zone consists of four main parts:

- Heating Elements: Generate the heat, commonly made from the primary hot zone material (graphite or refractory metals).

- Insulation or Heat Shields: Contain the thermal energy, preventing it from damaging the outer furnace chamber.

- Support Structure: A framework that holds the elements and insulation in place.

- Hearth: The base platform that supports the workload during processing.

Metallic Hot Zones: The Standard for Purity

Refractory metals are the traditional choice for applications where process contamination is a critical concern.

Why Molybdenum and Tungsten?

The primary advantage of molybdenum (Mo) and tungsten (W) is their exceptionally high melting point and low vapor pressure. This makes them dimensionally stable and durable at the extreme temperatures required in vacuum and crystal growth furnaces.

These metals maintain their integrity in a high-vacuum environment without significant outgassing, ensuring a clean processing atmosphere.

Typical Applications

Metallic hot zones are preferred for processes like the vacuum brazing of sensitive alloys, medical implant manufacturing, and certain types of crystal growth where any carbon contamination from a graphite element would compromise the final product.

Graphite Hot Zones: The Choice for Speed and Versatility

Graphite-based hot zones have become increasingly prevalent due to their excellent thermal properties and cost-effectiveness.

The Advantage of High-Purity Graphite

Graphite possesses outstanding thermo-mechanical properties. It is strong at high temperatures and has a low thermal mass, allowing it to heat up and cool down very quickly. This significantly reduces overall process cycle times, increasing throughput.

While robust, graphite hot zones are often designed for simple and fast replacement, which is beneficial when processing aggressive materials that may degrade the components over time.

The Rise of Carbon-Carbon Composites

Carbon-Carbon (C-C) composites are an advanced evolution of traditional graphite. For the same power output, C-C heating elements can be made much thinner.

This lower mass means they store even less heat. This is a significant advantage as it directly improves the furnace's cooling rate, further shortening cycle times.

Understanding the Trade-offs: Metal vs. Graphite

Choosing the correct material requires a clear understanding of the compromises involved with each option.

Process Purity and Contamination

This is the most critical distinction. Metallic hot zones are inherently cleaner and are the only choice when carbon contamination must be avoided. Graphite hot zones, by their nature, can introduce carbon into the atmosphere, which is unacceptable for certain materials.

Thermal Efficiency and Cycle Time

Due to lower thermal mass, graphite and C-C hot zones offer much faster heating and, more importantly, faster cooling rates. This leads to shorter cycles and higher productivity compared to their metallic counterparts, which retain more heat.

Durability and Lifespan

Refractory metals like molybdenum can become brittle after repeated thermal cycles, a phenomenon known as recrystallization. Graphite does not have this issue, but it can be slowly consumed or eroded when used with materials that react aggressively with carbon at high temperatures.

Cost Considerations

Generally, graphite hot zones have a lower initial purchase price and replacement component cost compared to molybdenum or tungsten systems, making them an economical choice for a wide range of general-purpose applications.

Making the Right Choice for Your Application

Your final decision should be guided by the non-negotiable requirements of your specific process.

- If your primary focus is ultimate purity for sensitive alloys or specific crystals: A metallic hot zone made of molybdenum or tungsten is the necessary choice to prevent carbon contamination.

- If your primary focus is maximum throughput and rapid cycle times: A graphite or carbon-carbon composite hot zone is superior due to its low thermal mass and faster cooling capabilities.

- If your primary focus is versatility and cost-effectiveness for general heat treating: A high-purity graphite hot zone provides an excellent balance of performance, durability, and operational cost.

Understanding these core material differences empowers you to select a furnace design that precisely matches your technical and operational goals.

Summary Table:

| Material Type | Key Advantage | Best For |

|---|---|---|

| Molybdenum / Tungsten | Ultimate process purity, no carbon contamination | Sensitive alloys, medical implants, specific crystal growth |

| Graphite / Carbon-Carbon | Fast heating/cooling, high throughput, cost-effective | General heat treating, processes requiring rapid cycle times |

Still unsure which hot zone material is right for your process? The experts at KINTEK can help. We specialize in lab equipment and consumables, providing tailored solutions for your high-temperature furnace needs. Our team will analyze your specific requirements for purity, cycle time, and budget to recommend the optimal hot zone configuration. Contact KINTEK today for a personalized consultation and unlock the full potential of your laboratory.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What are the steps in vacuum brazing? Achieve Superior, Clean Metallurgical Bonds

- What is vacuum heating? Achieve Purity and Precision in High-Temperature Processing

- Will brazing stick to cast iron? A Low-Heat Joining Solution for Crack-Free Repairs

- What is the role of a Vacuum Drying Oven in aluminum-coated graphite composite pretreatment? Ensure Material Integrity

- What is the difference between batch and continuous furnace? Choose the Right Furnace for Your Production Needs

- What are three types of carburizing? A Guide to Pack, Gas, and Liquid Methods

- What is the purpose of using a vacuum drying oven after ball milling NaSICON? Ensure Phase Purity and Homogeneity

- Why is a high-vacuum high-temperature furnace necessary for fusion experiments? Ensure Data Validity and Precision