At its core, a refractory kiln uses non-metallic insulation materials designed to retain their strength at extreme temperatures, typically above 1000°F. The most common materials used are firebrick and ceramic fibers, which serve to protect the kiln's structural shell and minimize heat loss during operation.

The selection of a specific refractory material is not a one-size-fits-all decision. It is a critical engineering choice driven by the unique temperature, chemical, and abrasive conditions of the process being performed inside the kiln.

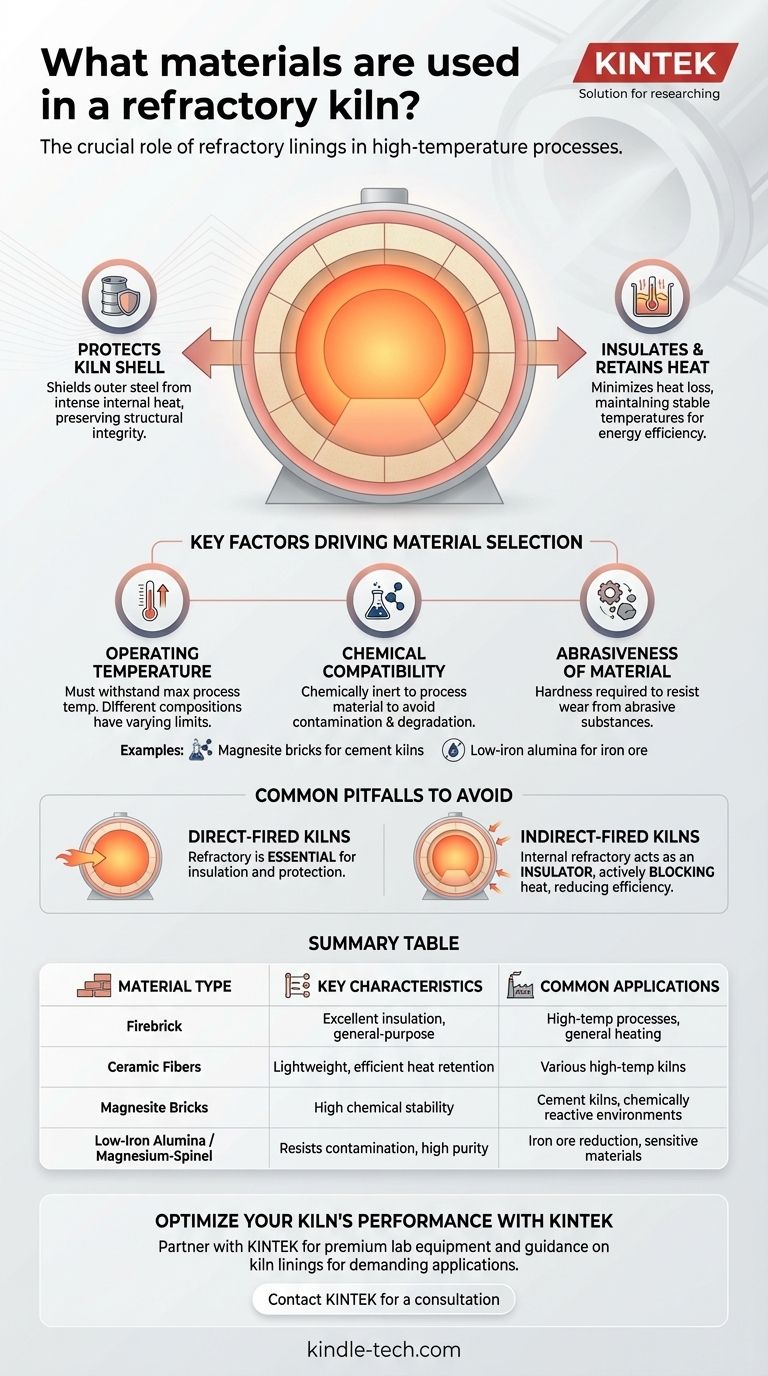

The Core Function of Refractory Materials

The refractory layer in a kiln serves two primary, interconnected purposes. Understanding these functions is key to appreciating why material selection is so important.

Protecting the Kiln Shell

The primary job of the refractory is to act as a protective barrier. It shields the outer steel shell of the kiln drum from the intense internal heat.

Without this layer, the structural integrity of the kiln itself would be compromised very quickly.

Insulating and Retaining Heat

Beyond protection, the refractory layer is a powerful insulator. It minimizes the amount of heat that escapes through the kiln shell.

This heat retention is crucial for maintaining stable process temperatures and improving the overall energy efficiency of the operation.

Key Factors Driving Material Selection

The choice of refractory is dictated by the specific demands of the industrial process. Three factors are paramount in this decision.

Kiln Operating Temperature

The first consideration is the maximum temperature the material must withstand. Different refractory compositions have different service temperature limits.

Chemical Compatibility

The refractory material must be chemically inert relative to the product being processed. A chemical reaction between the refractory and the process material can lead to contamination and rapid degradation of the kiln lining.

For example, magnesite bricks are often used in cement kilns due to their chemical stability in that environment, while low-iron alumina or magnesium-spinel bricks are preferred for iron ore reduction processes.

Abrasiveness of Process Material

The physical nature of the material being heated also matters. If the material is highly abrasive, the refractory must be hard enough to resist the constant wear and tear as it tumbles through the kiln.

Common Pitfalls to Avoid

While essential for many kilns, adding a refractory layer is not a universal solution. The context of the kiln's heating method is critical.

The Inefficiency in Indirect-Fired Kilns

Refractory is a defining component of direct-fired rotary kilns, where the flame and heat are applied directly to the material.

However, in an indirect-fired kiln, the shell is heated from the outside. Adding an internal refractory layer in this scenario would act as an insulator, actively blocking heat from reaching the process material and drastically reducing efficiency.

Making the Right Choice for Your Goal

Selecting the correct refractory lining is essential for the longevity, safety, and efficiency of your kiln. Your decision should be guided by the specific demands of your industrial process.

- If your primary focus is handling chemically reactive materials (like cement): Choose a refractory specifically formulated for chemical compatibility, such as magnesite bricks.

- If your primary focus is processing sensitive materials (like iron ore): Opt for specialized compositions like low-iron alumina or magnesium-spinel bricks to avoid contamination.

- If your primary focus is general high-temperature insulation: Firebrick and ceramic fibers are the industry-standard starting points for effective heat protection and retention.

Ultimately, choosing the right refractory is a foundational decision that ensures the long-term performance and efficiency of your high-temperature process.

Summary Table:

| Material Type | Key Characteristics | Common Applications |

|---|---|---|

| Firebrick | Excellent insulation, general-purpose | High-temperature processes, general heating |

| Ceramic Fibers | Lightweight, efficient heat retention | Various high-temperature kilns |

| Magnesite Bricks | High chemical stability | Cement kilns, chemically reactive environments |

| Low-Iron Alumina / Magnesium-Spinel | Resists contamination, high purity | Iron ore reduction, processing sensitive materials |

Optimize Your Kiln's Performance with the Right Refractory Lining

Choosing the correct refractory material is critical for the efficiency, safety, and longevity of your high-temperature processes. The wrong choice can lead to energy loss, contamination, or rapid equipment failure.

KINTEK is your partner in high-temperature processing. We specialize in supplying premium lab equipment and consumables, including guidance on kiln linings for demanding industrial and research applications. Our experts can help you select materials that meet your specific requirements for temperature, chemical compatibility, and abrasion resistance.

Let us help you protect your investment and enhance your process efficiency.

Contact KINTEK today for a consultation on the ideal refractory solution for your kiln.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products