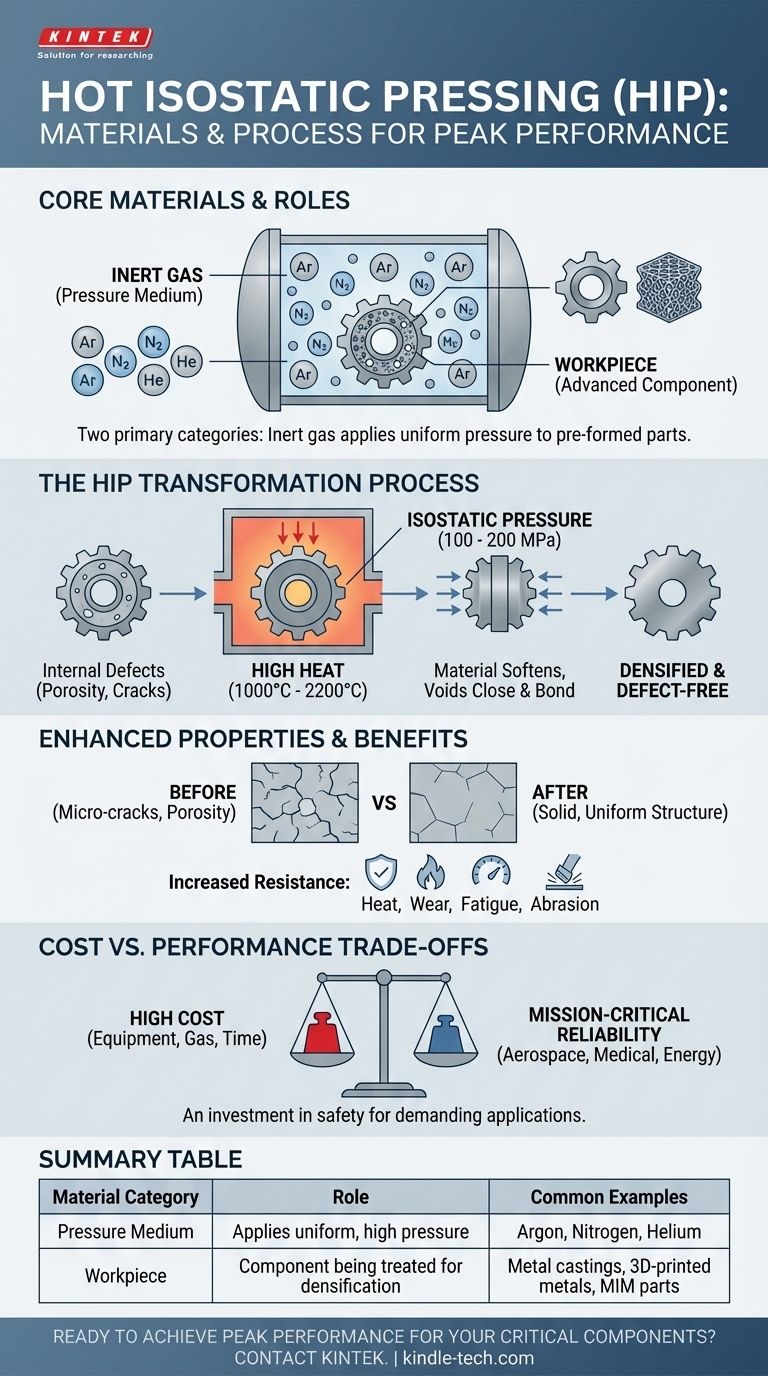

In hot isostatic pressing (HIP), the process primarily uses two categories of materials: an inert gas as the pressure medium and the advanced engineering components being treated. The most common gas is high-purity argon, which applies uniform pressure to parts made from materials like high-performance metal alloys, castings, and 3D-printed metals to eliminate internal flaws.

The core principle of HIP is not about the specific materials themselves, but rather the application of an inert gas under extreme heat and pressure to fundamentally perfect the internal structure of a pre-formed part, elevating its performance and reliability to the highest possible standard.

The Role of Each Material in the HIP Process

To understand the system, it's best to separate the materials used for the process from the materials being processed. Each plays a distinct and critical role.

The Pressure Medium: Inert Gas

The entire process relies on using a gas to transmit pressure uniformly onto the part. This gas must be inert, meaning it will not chemically react with the component, even at extreme temperatures.

The most common choice is argon, which is favored for its inertness and availability. Other gases like nitrogen or helium can also be used depending on the specific application and material being treated.

The Workpiece: Advanced Engineering Components

HIP is not a fabrication method; it is a post-processing treatment for parts already formed. It is specifically used on components where internal integrity is paramount.

Common categories include:

- Metal and alloy castings

- Metal Injection Molded (MIM) parts

- Products from metal 3D printing (additive manufacturing)

These manufacturing methods can leave behind microscopic internal defects. HIP is the definitive step to remove them.

How HIP Transforms Material Properties

The combination of high heat and isostatic (uniform) pressure forces the material to densify, fundamentally changing its internal structure and mechanical properties.

The Mechanism of Densification

The process takes place inside a specialized, high-strength pressure vessel. A typical cycle involves temperatures from 1000°C to 2200°C and pressures from 100 to 200 MPa.

The high temperature softens the material, reducing its yield strength. The immense, uniform gas pressure then causes the material to plastically deform on a microscopic level, permanently closing and bonding any internal voids.

Eliminating Critical Internal Defects

The primary goal of HIP is to eliminate flaws that can act as stress concentrators and lead to premature failure.

These defects include:

- Porosity (small gas-filled voids)

- Micro-cracks

- Internal segregation of alloys

By removing these initiation sites for failure, the material's overall performance is dramatically improved.

The Result: Enhanced Service Life

Parts treated with HIP exhibit superior mechanical properties. The process significantly increases resistance to heat, wear, fatigue, and abrasion.

This is why HIP is essential for components used in extreme environments, such as power generation turbines and subsea oil pipelines, where material failure would have severe consequences.

Understanding the Trade-offs: Cost vs. Performance

While HIP offers unparalleled benefits for material integrity, it is an expensive and specialized process that is not suitable for all applications.

The Inherent Cost of the Process

The equipment required to safely contain extreme temperatures and pressures is complex and expensive to build and maintain.

Furthermore, the process gases, particularly high-purity argon, are a significant operational cost. The lengthy cycle times, including heating, pressurization, and cooling, also contribute to the expense.

When the Cost is Justified

The high cost of HIP is reserved for applications where performance and reliability are non-negotiable.

For mission-critical components in the aerospace, energy, defense, and medical industries, the risk of material failure far outweighs the cost of the HIP treatment. It is an investment in safety and longevity.

Making the Right Choice for Your Goal

Deciding whether to use HIP depends entirely on the performance requirements of your component.

- If your primary focus is mission-critical performance: HIP is an essential finishing step to ensure maximum density, remove internal defects, and guarantee reliability under extreme stress.

- If your primary focus is improving 3D-printed metal parts: HIP is a vital post-processing tool for closing the inherent porosity from the printing process, achieving material properties comparable to traditional forgings.

- If your primary focus is producing standard commercial components: The high cost and complexity of HIP are likely unnecessary, as conventional manufacturing methods provide sufficient quality for less demanding applications.

Ultimately, hot isostatic pressing is a powerful tool for achieving the absolute peak of material performance when failure is not an option.

Summary Table:

| Material Category | Role in HIP Process | Common Examples |

|---|---|---|

| Pressure Medium | Applies uniform, high pressure | Argon, Nitrogen, Helium |

| Workpiece | Component being treated for densification | Metal castings, 3D-printed metals, MIM parts |

Ready to achieve peak performance for your critical components?

Hot isostatic pressing is the definitive solution for eliminating internal defects in high-value parts. At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for reliable HIP processes and material analysis.

Our expertise supports industries where failure is not an option, including aerospace, medical, and energy. Let us help you ensure the utmost reliability and longevity of your materials.

Contact our experts today to discuss how KINTEK's solutions can enhance your material performance and meet your mission-critical needs.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What core processing conditions does a vacuum hot press furnace provide? Achieve High-Density Cu-SiC/Diamond Composites

- What role does a high-purity graphite mold play during hot pressing? Optimize Boron Carbide Sintering at 1850°C

- How does a vacuum hot press sintering furnace improve the density of TZC molybdenum alloys? Achieve >98% Density

- Why must a vacuum hot press furnace be used for sintering Ti-3Al-2.5V alloys? Ensure High-Performance Titanium Quality

- What is the spark plasma sintering method? Achieve Rapid, High-Density Material Consolidation

- What role does a graphite mold play in the Hot Pressing (HP) sintering process of LTPO? Master High-Density Sintering

- What role does a vacuum hot press furnace play in BMG consolidation? Optimize Bulk Metallic Glass Density

- How does a vacuum hot-press sintering furnace produce high-density Mo-Na alloy targets? Precision Thermal Engineering