At its core, a hydraulic press is built from steel. The immense forces generated by these machines demand a material with exceptional strength and rigidity. While "steel" is the simple answer, the specific grade and type of steel alloy used for different components are what truly define the press's capability, safety, and longevity.

The choice of metal in a hydraulic press is not a single decision but a series of deliberate engineering choices. The goal is to select specific steel alloys for each component—the frame, cylinders, and pistons—that can withstand enormous pressure, resist deformation, and endure millions of cycles without failing.

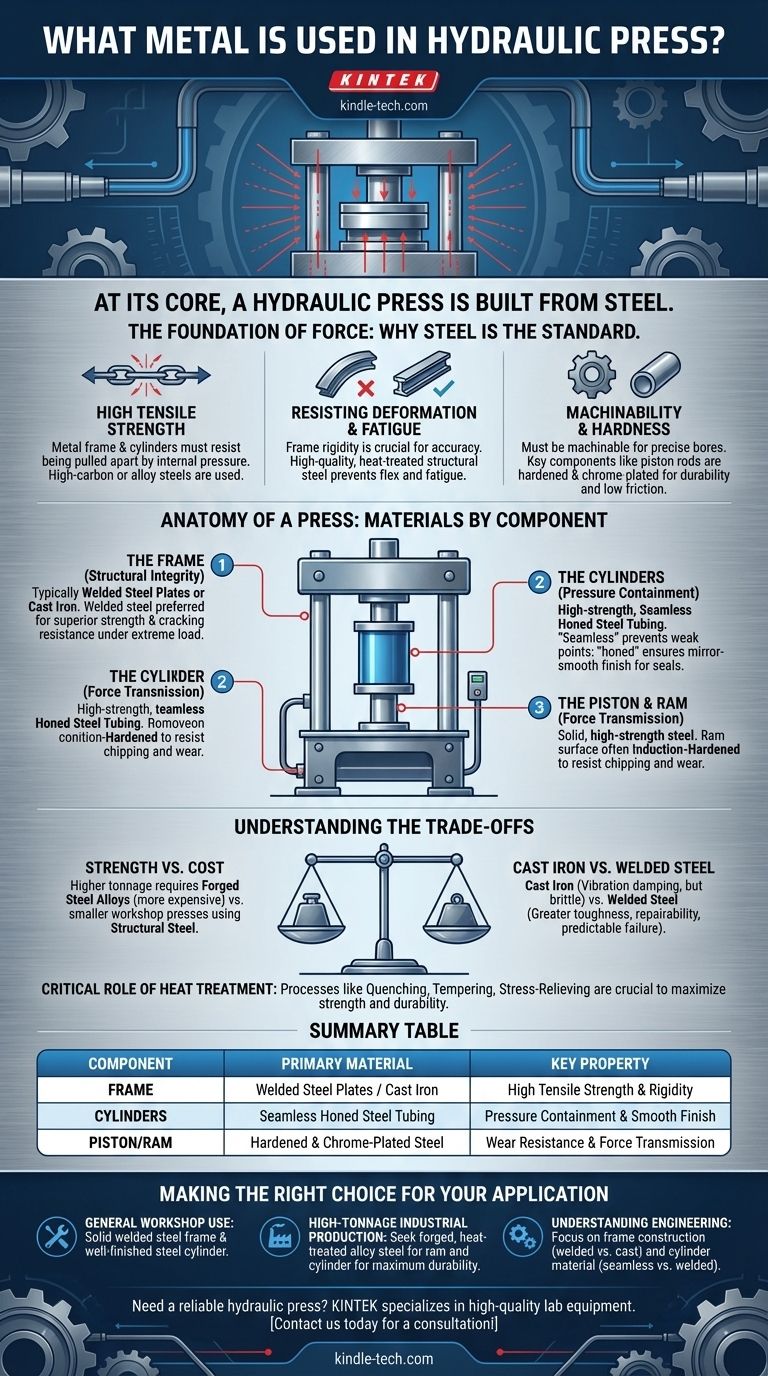

The Foundation of Force: Why Steel is the Standard

A hydraulic press operates on Pascal's principle, multiplying a small force into an immense one. The materials used must contain and direct this power safely and effectively.

The Demand for High Tensile Strength

The metal frame and cylinders are under constant tension. They must have high tensile strength to resist being pulled apart by the internal hydraulic pressure. This is why high-carbon or alloy steels are the materials of choice.

Resisting Deformation and Fatigue

The main structure, or frame, must be incredibly rigid. Any flex or deformation under load would compromise the accuracy of the pressing operation. Manufacturers use high-quality, often heat-treated, structural steel to ensure the frame remains stable over a lifetime of use. This also prevents metal fatigue from the repeated stress of press cycles.

Machinability and Hardness

While incredibly strong, the steel used must also be machinable to create the precise, smooth bores of the hydraulic cylinders and pistons. After machining, key components like the piston rod are often hardened and chrome-plated to create a durable, low-friction surface that can withstand constant movement and maintain a perfect seal.

Anatomy of a Press: Materials by Component

Different parts of the press face different stresses, requiring different material properties.

The Frame: Ensuring Structural Integrity

The frame, whether an H-frame or C-frame design, is the backbone of the machine. It is typically constructed from heavy-duty welded steel plates or, in some cases, a large cast iron structure. Welded steel is generally preferred for its superior strength and resistance to cracking under extreme loads.

The Cylinders (Ram and Plunger): Containing the Pressure

The cylinders are pressure vessels. They are most often made from high-strength, seamless honed steel tubing. "Seamless" is critical, as welds can be weak points. The inside surface is "honed" to a mirror-smooth finish to ensure the hydraulic seals are effective and do not wear out prematurely.

The Piston and Ram: Transmitting the Force

The piston that moves within the cylinder and the ram that contacts the workpiece are made from solid, high-strength steel. The ram's surface is often induction-hardened to resist chipping and damage from the dies or workpieces it presses against.

Understanding the Trade-offs

The specific material choices involve balancing performance, longevity, and cost. Not all presses are created equal.

Strength vs. Cost

Higher-tonnage industrial presses require more advanced and expensive materials, such as forged steel alloys, for critical components. A smaller workshop press may use more common, but still robust, structural steel to manage costs while ensuring safety for its intended load.

Cast Iron vs. Welded Steel Frames

Cast iron frames have excellent vibration-damping qualities and can be formed into complex shapes. However, they can be brittle and prone to catastrophic failure if overloaded. Modern presses predominantly use fabricated and welded steel frames, which offer greater toughness, repairability, and more predictable failure modes (bending before breaking).

The Critical Role of Heat Treatment

Simply choosing the right steel is not enough. Processes like quenching, tempering, and stress-relieving are crucial post-fabrication steps. Heat treatment realigns the steel's molecular structure, maximizing its strength and durability and removing internal stresses created during welding.

Making the Right Choice for Your Application

Understanding the materials helps you evaluate the quality and suitability of a hydraulic press.

- If your primary focus is general workshop use: A press with a solid, welded structural steel frame and a well-finished steel cylinder offers the best balance of performance and value.

- If your primary focus is high-tonnage industrial production: Seek out presses that specify forged, heat-treated alloy steel for the ram and cylinder, as this indicates a design built for maximum durability and precision under continuous use.

- If your primary focus is understanding the engineering: Pay close attention to the frame construction (welded steel vs. cast iron) and the cylinder material (seamless vs. welded tubing), as these are the primary indicators of the machine's robustness and safety.

Ultimately, the metal in a hydraulic press is a testament to engineering, where material science is applied to safely harness and deliver incredible force.

Summary Table:

| Component | Primary Material | Key Property |

|---|---|---|

| Frame | Welded Steel Plates / Cast Iron | High Tensile Strength & Rigidity |

| Cylinders | Seamless Honed Steel Tubing | Pressure Containment & Smooth Finish |

| Piston/Ram | Hardened & Chrome-Plated Steel | Wear Resistance & Force Transmission |

Need a reliable hydraulic press for your lab or workshop? The right equipment is crucial for safety and precision. KINTEK specializes in high-quality lab equipment, including robust hydraulic presses built with the superior materials discussed here. Let our experts help you select the perfect press for your specific application. Contact us today for a consultation!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- How much psi can a hydraulic press make? From 2,000 PSI to over 50,000 PSI Explained

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production