At its core, tempering is a heat treatment process primarily applied to specific iron-based alloys. The metals that can be tempered are those that can first be hardened, a category that includes the vast majority of steels and certain types of cast iron. This capability is dependent on the metal having sufficient carbon content to undergo a critical structural change when heated and then rapidly cooled.

The ability of a metal to be tempered is not an independent property, but a direct consequence of its ability to be hardened. Therefore, tempering is almost exclusively applied to ferrous metals—like steel and cast iron—that contain enough carbon to form a hard, brittle structure called martensite upon quenching.

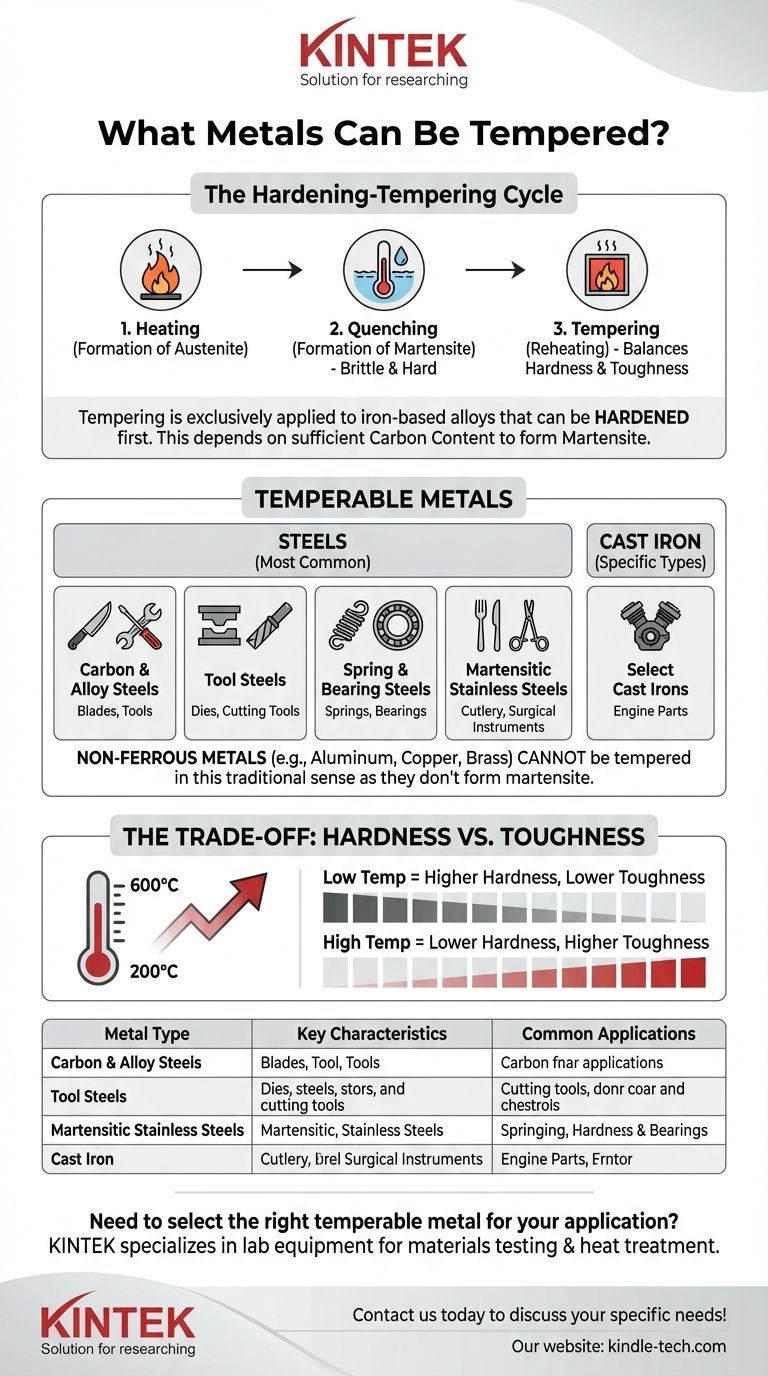

The Fundamental Requirement: The Ability to Harden

Tempering is never a standalone process. It is the second step in a two-part heat treatment designed to achieve a precise balance of mechanical properties.

The Critical Role of Carbon and Iron

The entire process hinges on the unique relationship between iron and carbon atoms in steel. When steel is heated to a high temperature, its crystal structure changes and allows carbon atoms to dissolve into the iron.

Creating Martensite: The Hardening Step

If the hot steel is then cooled very rapidly (a process called quenching), the carbon atoms are trapped within the iron's crystal structure. This creates a new, highly strained, and very hard microstructure known as martensite. This hardened state is the necessary prerequisite for tempering.

Why Most Non-Ferrous Metals Can't Be Tempered

Metals like aluminum, copper, brass, or titanium do not have this specific iron-carbon relationship. Their crystal structures do not form martensite through quenching. While they can be strengthened by other methods like "age hardening" or "work hardening," they cannot be tempered in the traditional sense.

What Steels and Irons Can Be Tempered?

Practically any steel or iron alloy that can be hardened can subsequently be tempered. The specific alloy is chosen based on the desired final properties.

Carbon and Alloy Steels

This is the largest and most common category. It includes everything from simple high-carbon steels used for files and blades to complex alloy steels containing elements like chromium, molybdenum, and vanadium. These alloying elements improve the steel's ability to harden deeply and uniformly.

Tool Steels

As the name implies, these are specialized alloys designed for tools, dies, and cutting edges. They are formulated for exceptional hardness and wear resistance, which is achieved through a precise hardening and tempering cycle. Examples include hot-worked and cold-worked tool steels.

Spring and Bearing Steels

These alloys are designed to balance hardness with toughness and fatigue resistance. Spring steels are tempered at higher temperatures to gain the flexibility they need, while anti-friction bearing steels are tempered for extreme hardness and dimensional stability.

Martensitic Stainless Steels

Most common stainless steels (like those used in kitchen sinks) are austenitic and cannot be hardened by heat treatment. However, martensitic stainless steels have a different composition that allows them to be hardened and tempered, making them suitable for cutlery, surgical instruments, and high-strength components.

Understanding the Trade-off: Hardness vs. Toughness

The entire purpose of tempering is to strategically trade a small amount of hardness for a significant gain in toughness.

The Brittleness of Fully Hardened Steel

Steel that has been quenched to form 100% martensite is at its maximum hardness. However, it is also extremely brittle, like glass. A sharp impact could cause it to shatter, making it useless for most applications.

How Tempering Sacrifices Hardness for Toughness

Tempering involves reheating the hardened steel to a precise temperature (well below the initial hardening temperature) and holding it there. This controlled heating allows some of the trapped carbon atoms to move, relieving the intense internal stresses within the martensite structure.

The Tempering Spectrum

The final properties are dictated by the tempering temperature. A low temperature (e.g., 200°C / 400°F) relieves just enough stress to reduce brittleness while retaining most of the hardness. A high temperature (e.g., 600°C / 1100°F) results in a much greater loss of hardness but a massive gain in toughness and ductility.

Making the Right Choice for Your Goal

Selecting a temperable metal and its corresponding heat treatment is about defining the most critical property for the final application.

- If your primary focus is maximum hardness and wear resistance: You will work with high-carbon tool steels or bearing steels, using a very low tempering temperature.

- If your primary focus is toughness and impact resistance: You will select medium-carbon alloy steels and use a higher tempering temperature to create components like axles, structural bolts, or springs.

- If your primary focus is corrosion resistance plus strength: You must specify a martensitic stainless steel, which is the only class of stainless that can undergo this hardening and tempering process.

Ultimately, choosing a temperable metal is about selecting a material whose properties can be precisely engineered to navigate the fundamental trade-off between hardness and toughness.

Summary Table:

| Metal Type | Key Characteristics | Common Applications |

|---|---|---|

| Carbon & Alloy Steels | Can be hardened & tempered; properties vary with carbon content. | Blades, tools, structural components. |

| Tool Steels | High hardness & wear resistance after precise heat treatment. | Dies, cutting tools, molds. |

| Martensitic Stainless Steels | Corrosion resistance combined with high strength from tempering. | Cutlery, surgical instruments. |

| Cast Iron | Certain types can be hardened and tempered. | Engine parts, heavy-duty components. |

Need to select the right temperable metal for your application?

The precise balance of hardness and toughness is critical for component performance. KINTEK specializes in lab equipment and consumables for materials testing and heat treatment processes. Our experts can help you choose the right materials and equipment to achieve your desired results.

Contact us today to discuss your specific needs and learn how we can support your laboratory's success!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- How to use a muffle furnace? A Step-by-Step Guide to Safe and Effective Operation

- What is a muffle furnace used for metallurgy of? Achieve Precise Heat Treatment & Material Analysis

- What is a chamber furnace? A Guide to Precision Thermal Processing

- What problem is addressed by high-temperature molten salt or sodium peroxide fusion? Overcome Catalyst Lattice Stability

- What is the effect of cooling rate in heat treatment? Control Hardness, Strength, and Ductility

- What is the muffle furnace 1800 degree? High-Temp Precision for Advanced Materials

- Why are precisely controlled laboratory ovens essential for curing aerospace composites? Achieve Flight-Ready Performance

- What are the methods of ash determination? Choosing the Right Technique for Accurate Mineral Analysis