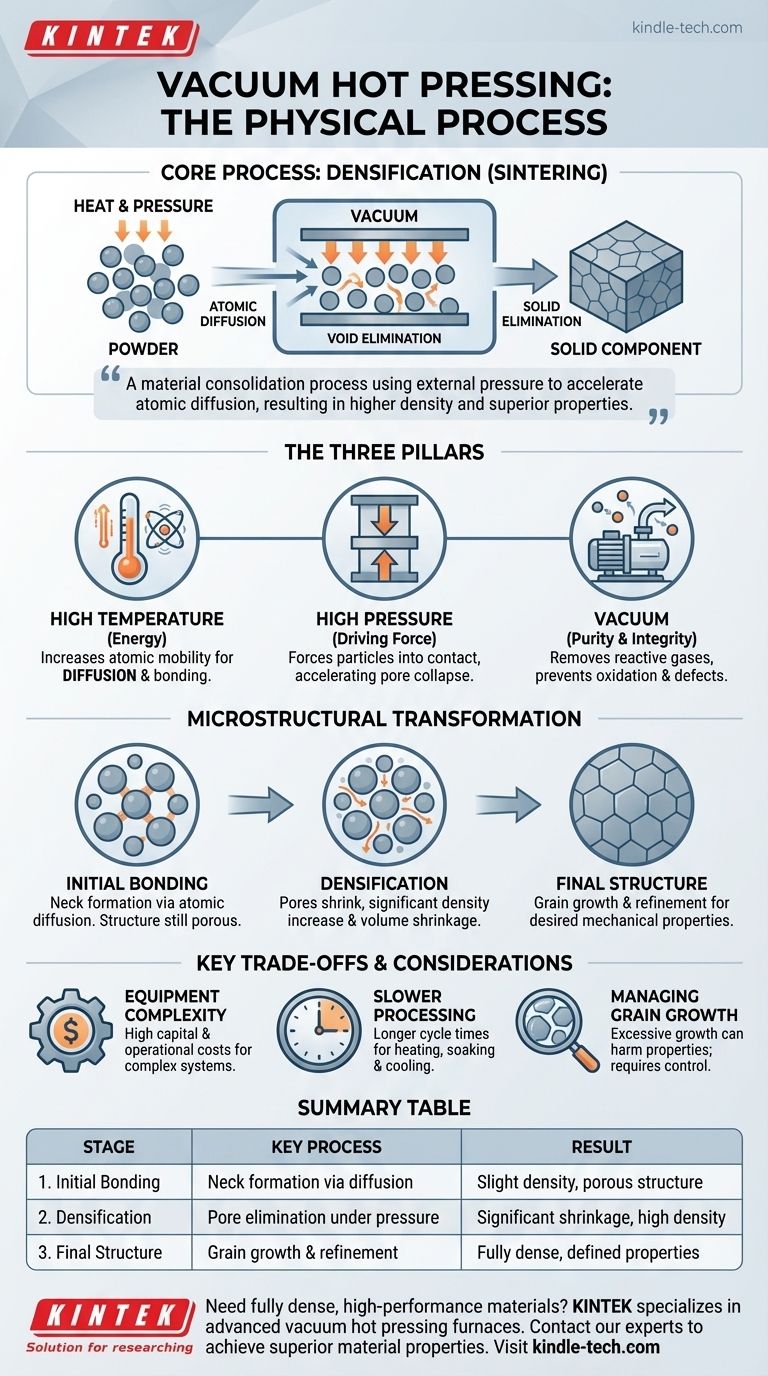

At its core, the physical process occurring inside a vacuum hot pressing furnace is a highly controlled form of sintering called densification. Under the combined influence of intense heat and mechanical pressure in a vacuum, individual solid particles of a material are forced to bond and fuse together. This eliminates the empty spaces between them, shrinking the total volume and transforming a loose powder into a fully dense, solid component.

Vacuum hot pressing is a material consolidation process that uses external pressure to accelerate the atomic diffusion driven by heat. This synergy results in a final product with higher density and superior mechanical properties compared to what is achievable with heat alone.

The Three Pillars of Vacuum Hot Pressing

The unique environment inside the furnace is defined by three critical factors working in concert. Each plays a distinct and essential role in the material's transformation.

The Role of High Temperature

High temperature provides the foundational energy for the process. It increases the vibrational energy of atoms within the material particles, making them mobile.

This atomic mobility is what allows diffusion—the movement of atoms—to occur across the contact points between individual particles, forming strong metallurgical bonds.

The Role of High Pressure

While temperature enables bonding, high pressure is the driving force for consolidation. The externally applied mechanical pressure physically forces the solid particles into intimate contact.

This pressure accelerates the collapse of voids (pores) and enhances the rate of material transfer between grains, leading to a much faster and more complete densification than conventional sintering.

The Role of Vacuum

The vacuum or controlled atmosphere is crucial for material purity and integrity. It removes atmospheric gases like oxygen and nitrogen that could react with the material at high temperatures.

This prevents the formation of undesirable oxides or nitrides and helps extract any trapped gases from within the powder mass, which would otherwise lead to internal defects and porosity in the final part.

From Powder to Solid: The Microstructural Transformation

The journey from a collection of individual particles to a dense, polycrystalline body happens in overlapping stages, fundamentally altering the material's internal structure.

Stage 1: Initial Particle Bonding

As the material heats up, the points where particles touch begin to form small "necks" or bridges. This is the initial stage of bonding, driven by atomic diffusion. The overall density increases slightly, but the structure is still highly porous.

Stage 2: Pore Elimination and Densification

As temperature and pressure are maintained, material transfer accelerates significantly. Atoms move from the grain boundaries to fill the voids between particles.

The pores gradually shrink and become isolated, while the grains grow and change shape to fit together more tightly. This is where the most significant increase in density and volume shrinkage occurs.

Stage 3: Grain Growth and Final Structure

In the final stage, nearly all porosity has been eliminated. The primary remaining process is grain growth, where larger grains expand at the expense of smaller ones.

Proper control of time, temperature, and pressure is critical here to achieve the desired final grain size, which directly influences the material's mechanical properties like strength and hardness.

Understanding the Key Trade-offs

While powerful, the vacuum hot pressing process involves specific challenges and considerations that are critical for an engineer to understand.

Equipment Complexity and Cost

Vacuum hot pressing furnaces are complex and expensive systems. They require robust vacuum pumps, precision pressure application systems, and sophisticated temperature controls, leading to high capital and operational costs.

Slower Processing Cycles

Compared to other manufacturing methods, the process can be slow. Heating, soaking at temperature under pressure, and cooling must all be done carefully within the vacuum chamber, resulting in longer cycle times per part.

Managing Unwanted Grain Growth

The same conditions that promote densification—high temperature and time—also promote grain growth. If not carefully controlled, excessive grain growth can occur, which may be detrimental to the final mechanical properties of the material.

Making the Right Choice for Your Goal

Selecting this process depends entirely on the requirements of the final component.

- If your primary focus is achieving near-theoretical density: Vacuum hot pressing is ideal for eliminating the last few percent of residual porosity in high-performance ceramics or powder metals.

- If your primary focus is processing reactive or non-oxide materials: The controlled vacuum environment is essential to prevent the contamination and oxidation that would ruin materials like titanium, niobium, or boron carbide.

- If your primary focus is creating a specific, fine-grained microstructure: This process offers a powerful way to produce fully dense materials while minimizing grain growth, which is key to maximizing strength and toughness.

Ultimately, vacuum hot pressing provides a precise method for engineering advanced materials with properties that are impossible to create through conventional means.

Summary Table:

| Stage | Key Process | Result |

|---|---|---|

| 1. Initial Bonding | Neck formation between particles via atomic diffusion | Slight density increase, porous structure |

| 2. Densification | Pore elimination and material transfer under pressure | Significant volume shrinkage, high density |

| 3. Final Structure | Grain growth and microstructural refinement | Fully dense solid with defined mechanical properties |

Need to create fully dense, high-performance materials?

At KINTEK, we specialize in advanced lab equipment, including vacuum hot pressing furnaces. Our solutions are designed for researchers and engineers working with reactive metals, high-performance ceramics, and other advanced materials where achieving near-theoretical density and a controlled microstructure is critical.

We provide the technology and expertise to help you accelerate densification, prevent contamination, and achieve superior material properties that are impossible with conventional methods.

Contact our experts today to discuss how a KINTEK vacuum hot pressing furnace can meet your specific material development goals.

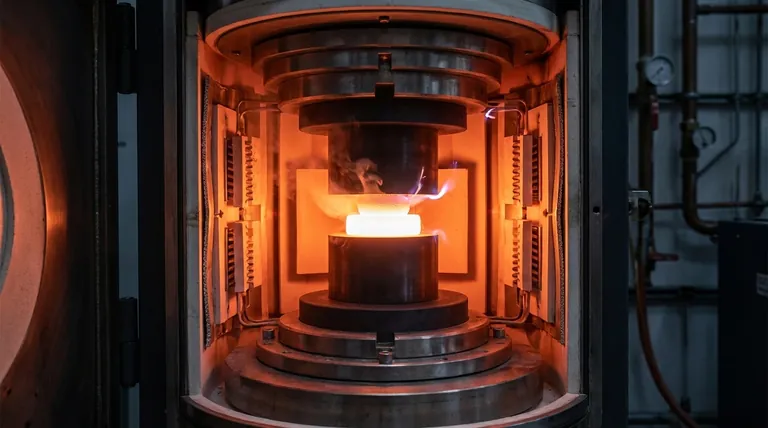

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

People Also Ask

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- Why is a high vacuum preferred over argon for sintering VC/Cu composites? Achieve Superior Wetting and Bond Strength

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production

- Why is precise temperature control necessary for SiC/Cu Vacuum Hot Pressing? Mastering the Cu9Si Interface Phase

- What is the function of a vacuum hot press furnace? Achieve High Densification in Al-Ti-Zr Synthesis