Strict adherence to safety protocols is non-negotiable when operating a muffle furnace. The extreme temperatures present significant risks, and precautions must cover personal protection, correct operational procedures, and environmental controls. This involves wearing appropriate heat-resistant gear, ensuring the furnace is on a stable and clear surface, never exceeding its rated temperature, and allowing it to cool naturally before opening the door.

A muffle furnace is not an appliance to be left unattended. Effective safety is a systematic process that begins before the furnace is turned on and ends only after it has completely cooled, with the primary goal of controlling extreme heat and preventing unexpected material reactions.

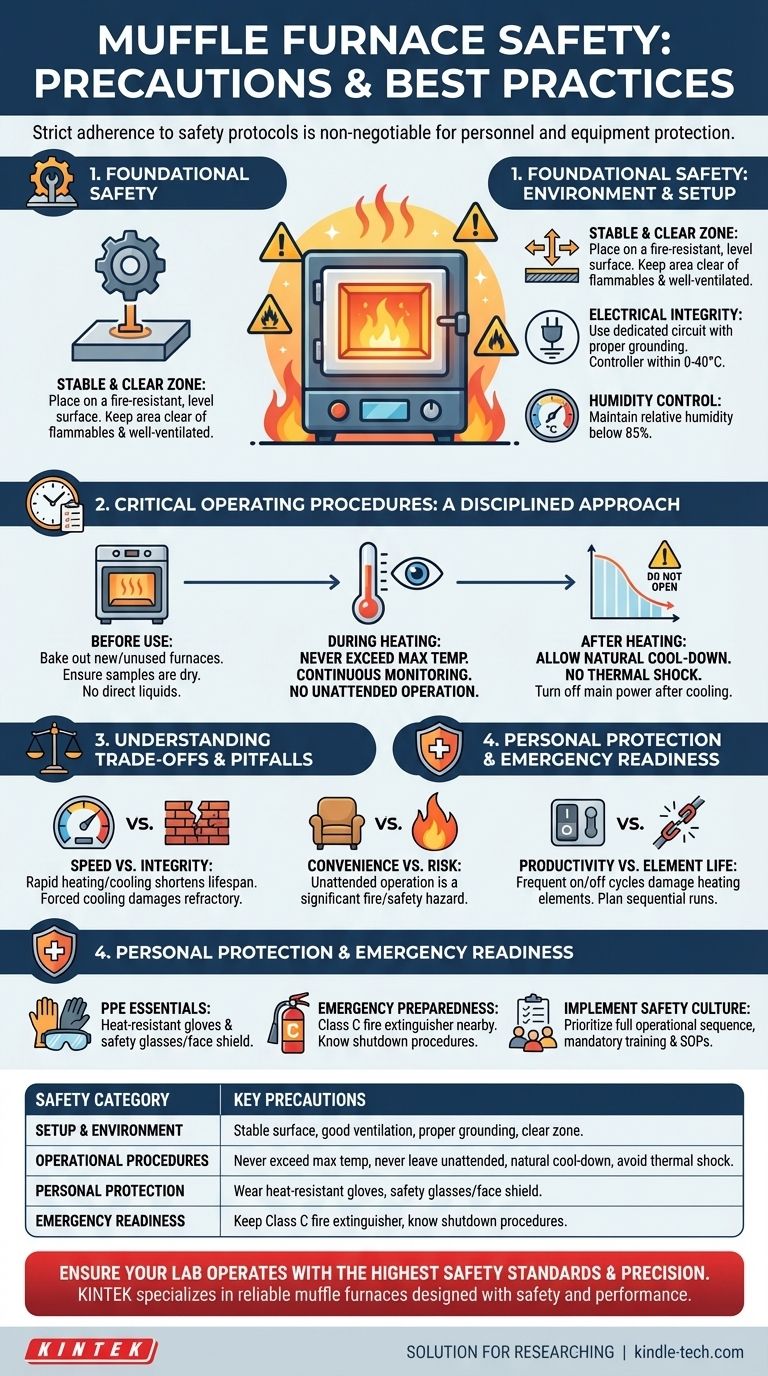

Foundational Safety: Environment and Setup

Proper setup is the first line of defense against accidents. The physical location and condition of the furnace and its surroundings are critical for safe operation.

Securing the Furnace Location

The furnace must be placed on a stable, level, and fire-resistant surface, such as a concrete platform. This prevents tipping and ensures it can bear the weight.

Ensure the area is well-ventilated to dissipate heat and any potential fumes from the materials being processed.

Electrical Grounding and Connections

The furnace requires a dedicated electrical circuit with the correct plugs, sockets, and fuses for its power rating. Proper grounding is mandatory to prevent electrical shock.

The controller unit should operate within its specified ambient temperature range, typically 0-40°C (32-104°F), and should not be placed directly on top of the furnace.

Maintaining a Clear and Safe Zone

The environment must be free of flammable, explosive, or corrosive materials. Keep a significant clearance around the furnace, as its outer jacket becomes extremely hot during operation.

The relative humidity should be kept below 85% to protect electrical components and refractory materials.

Critical Operating Procedures

A disciplined, step-by-step approach to operation minimizes risks to both the user and the equipment.

Before You Begin: Pre-Use Checks

If a furnace is new or has been unused for a long time, it must be baked out first. This involves a slow, gradual heating process to drive out any absorbed moisture from the refractory lining, preventing it from cracking.

Confirm that all samples are dry. Never place liquids directly into the furnace. Materials that may release grease or volatile gases must be heated in a sealed or properly vented container.

During Heating: Control and Monitoring

Never exceed the maximum rated temperature of the furnace, as this will damage the heating elements. Avoid operating at the maximum temperature for extended periods.

The furnace must be monitored throughout the entire heating cycle. A failure in the temperature controller could lead to a runaway thermal event. Never leave a furnace running unattended, especially overnight.

Load and unload samples only when the furnace is turned off and at a safe temperature. Avoid overloading the furnace chamber, as this can lead to uneven heating.

After Heating: The Cool-Down Process

Do not open the furnace door when the internal temperature is high (e.g., above 600°C). The sudden change in temperature, known as thermal shock, can crack the furnace lining and shatter samples.

Always allow the furnace to cool down naturally. Never attempt to accelerate cooling by opening the door or introducing cool air.

Once the experiment is complete and the furnace is cooling, turn off the main power supply. For storage, keep the furnace door closed to protect the refractory materials from absorbing atmospheric moisture.

Understanding the Trade-offs and Common Pitfalls

Seemingly minor deviations from procedure can have significant consequences for safety and equipment longevity.

Speed vs. Equipment Integrity

The most common pitfall is sacrificing proper procedure for speed. Rapid heating or cooling saves time but introduces immense stress on the furnace chamber and heating elements, drastically shortening their lifespan. Forced cooling is a primary cause of refractory damage.

Convenience vs. Inherent Risk

Leaving a furnace unattended is a significant gamble. While convenient, it completely removes your ability to respond to a controller malfunction, a power surge, or an unexpected reaction from your sample, creating a serious fire and safety hazard.

Productivity vs. Element Lifespan

Frequent on/off cycles can be detrimental. Each time the heating elements cool, the protective oxide layer that forms on them can flake off. Repeatedly cycling the power shortens the life of these critical components. It is often better to plan experiments to run sequentially rather than shutting down the furnace between short runs.

Personal Protection and Emergency Readiness

Your personal safety depends on using the right equipment and being prepared for the unexpected.

Personal Protective Equipment (PPE)

Always wear heat-resistant gloves and safety glasses or a face shield when working near the furnace, even if you are not opening the door. The type of glove must be rated for the temperatures you are working with.

Emergency Preparedness

Ensure a fire extinguisher appropriate for electrical fires (Class C) is located near the muffle furnace.

All operators must be aware of emergency shutdown procedures. If you notice any abnormalities—such as strange noises, smoke, or erratic temperature readings—shut off the power immediately and do not use the furnace until it has been inspected by qualified personnel.

Implementing a Culture of Safety

To ensure safe and reliable results, safety must be a shared responsibility grounded in clear procedures and proper training.

- If your primary focus is hands-on operation: Always prioritize the full operational sequence, from pre-use checks to natural cool-down, and never work without the correct PPE.

- If your primary focus is lab management: Implement mandatory training, create clear standard operating procedures (SOPs), and enforce a strict policy against unattended operation.

Ultimately, disciplined and safe operation is the foundation that enables accurate, repeatable, and successful work with a muffle furnace.

Summary Table:

| Safety Category | Key Precautions |

|---|---|

| Setup & Environment | Stable, fire-resistant surface; good ventilation; proper grounding; clear of flammables. |

| Operational Procedures | Never exceed max temperature; never leave unattended; allow natural cool-down; avoid thermal shock. |

| Personal Protection | Always wear heat-resistant gloves and safety glasses/face shield. |

| Emergency Readiness | Keep a Class C fire extinguisher nearby; know emergency shutdown procedures. |

Ensure your lab operates with the highest safety standards and precision. KINTEK specializes in high-quality, reliable muffle furnaces and lab equipment designed with safety and performance in mind. Our experts can help you select the right equipment and provide guidance on safe operation. Contact us today to discuss your laboratory needs and how we can support your success with durable, safe, and efficient solutions.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do heat treatment and mechanical processes affect material properties? Master the Science of Material Engineering

- What role does a high-temperature muffle furnace play in evaluating rice husk hydrolysis? Isolate Inorganic Components

- What is a muffle furnace used for burning? Mastering Controlled Thermal Processes

- What is the purpose of treating glass alteration gels at 300°C? Enhancing NMR Analysis for Material Science

- What is the final stage of sintering? Master the Final Pore Elimination for Maximum Density

- What is the specific function of a box resistance furnace in Li2MnO3 synthesis? Master Precursor Powder Preparation

- How do you determine the ash content of a food sample? Choose the Right Method for Accurate Mineral Analysis

- What is the function of a high-temperature muffle furnace in synthesizing La-Y-NbO4? Master Solid-Phase Diffusion