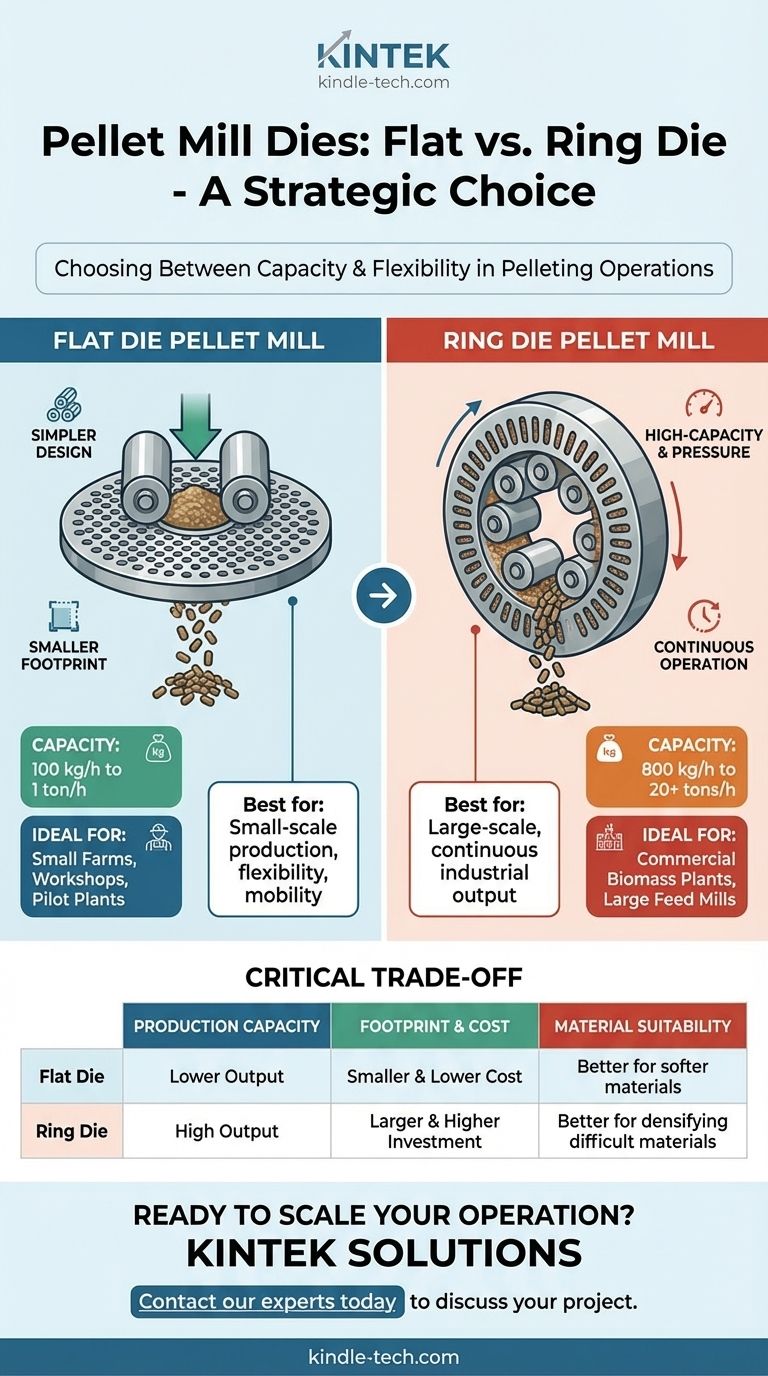

In pellet mills, there are two primary types of dies used to form the final product: the flat die and the ring die. The choice between them is fundamental, as it dictates the entire design, scale, and application of the pelleting operation.

The core distinction is one of scale and purpose. Flat die mills are designed for smaller, more flexible production environments, while ring die mills are built for high-capacity, continuous industrial applications.

Understanding the Flat Die Pellet Mill

The flat die mill represents the simpler and more accessible entry point into pellet production. Its design is straightforward and effective for specific use cases.

Core Design and Operation

A flat die is a horizontal, perforated metal disc, typically made of ductile cast iron. Raw material is fed onto the top of this stationary or rotating disc. A set of rollers then moves over the material, pressing it with force through the holes in the die to form pellets.

Key Characteristics

The defining feature of a flat die system is its simplicity and smaller footprint. This makes the machinery less space-consuming and easier to transport compared to its ring die counterpart.

Ideal Applications

Flat die mills are best suited for small-scale production. Their capacity, typically ranging from 100 kg/h to 1 ton/h, is ideal for small farms, workshops, or pilot plants where flexibility is more important than massive output.

Understanding the Ring Die Pellet Mill

The ring die mill is the workhorse of industrial-scale pellet production. Its design is engineered for high throughput and continuous operation.

Core Design and Operation

In this configuration, the die is a vertical, rotating ring with holes drilled radially. Raw material is fed into the center of the ring, where rollers press it outward against the inner surface, forcing it through the holes to create pellets.

Key Characteristics

The primary advantages of the ring die are high speed and immense pressure. This design generates the force necessary to handle large volumes of material efficiently, making it the standard for heavy-duty applications.

Ideal Applications

Ring die mills are the default choice for large-scale industrial settings. They are commonly found in commercial biomass fuel plants or large feed mills, with production capacities ranging from 800 kg/h to over 20 tons/h.

The Critical Trade-off: Capacity vs. Flexibility

Choosing between a flat and ring die is not about which is "better," but which is appropriate for the intended scale of the operation. The decision involves a direct trade-off between production volume and operational flexibility.

Production Capacity

The most significant difference is output. A flat die mill's capacity maxes out around 1 ton per hour, whereas a ring die mill starts at a similar capacity and can scale to over 20 tons per hour.

Footprint and Cost

The simpler design of a flat die mill translates to a smaller physical footprint and generally lower initial investment. Ring die systems are larger, more complex, and represent a significant capital expenditure geared toward industrial returns.

Material Suitability

While both can process various materials, the high pressure of a ring die is often preferred for densifying difficult or low-density biomass. The direct downward force of a flat die is sometimes considered advantageous for softer materials that may slip in a ring die system.

Choosing the Right Die for Your Operation

Your production goal is the single most important factor in selecting the correct die and mill type.

- If your primary focus is small-scale production, recipe testing, or mobility: A flat die mill provides the necessary flexibility and a lower barrier to entry.

- If your primary focus is high-volume, continuous industrial output for commercial sale: A ring die mill is the only viable option to achieve the required capacity and efficiency.

Understanding this fundamental distinction is the first step toward building a successful and appropriately scaled pelleting operation.

Summary Table:

| Feature | Flat Die Pellet Mill | Ring Die Pellet Mill |

|---|---|---|

| Best For | Small-scale production, flexibility, mobility | Large-scale, continuous industrial output |

| Typical Capacity | 100 kg/h to 1 ton/h | 800 kg/h to over 20 tons/h |

| Key Advantage | Lower cost, simpler operation, smaller footprint | High efficiency, high throughput, durability |

| Ideal Application | Small farms, workshops, pilot plants | Commercial biomass plants, large feed mills |

Ready to scale your pelleting operation with the right equipment?

KINTEK specializes in high-quality lab equipment and consumables, serving the precise needs of laboratories and production facilities. Whether you are testing materials on a small scale or ramping up to industrial production, our expertise ensures you get the most efficient and reliable pellet mill for your specific requirements.

Contact our experts today to discuss your project and discover how KINTEK can provide the perfect solution to enhance your productivity and achieve superior results.

Visual Guide

Related Products

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Single Horizontal Jar Mill

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

People Also Ask

- How does a planetary mill work? Harnessing High-Energy Impact for Nano-Grinding

- What are the advantages of planetary ball milling? Achieve High-Energy Grinding and Material Synthesis

- What is the principle of planetary ball mill? Achieve Rapid, High-Energy Grinding for Your Materials

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results

- What are the disadvantages of planetary ball mill? Key Drawbacks in Energy, Noise, and Wear