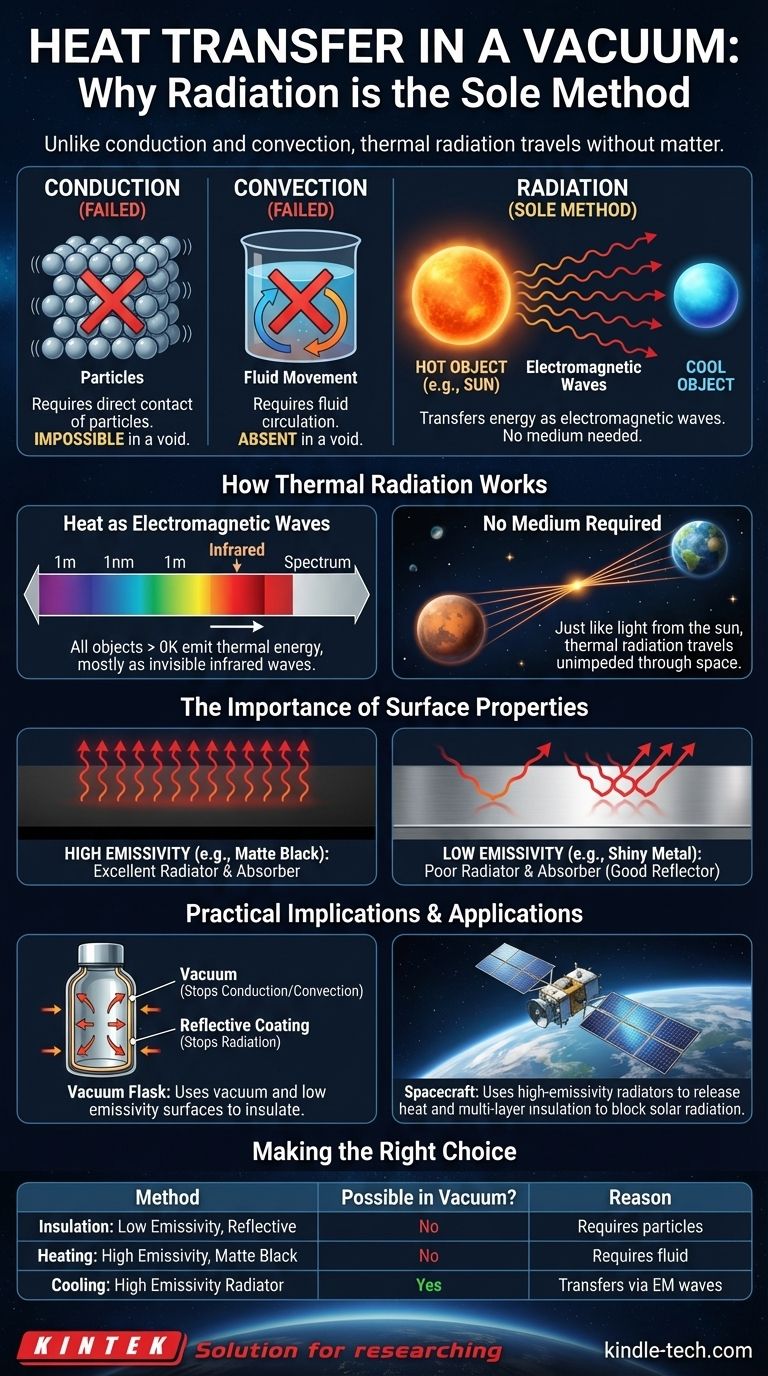

In a perfect vacuum, the sole method of heat transfer is thermal radiation. Unlike conduction or convection, which require the presence of matter to move thermal energy, radiation transfers heat in the form of electromagnetic waves, which can travel through the emptiness of space.

While conduction and convection depend on particle interactions, a vacuum is defined by the absence of particles. This leaves thermal radiation—the emission of energy as electromagnetic waves—as the only possible mechanism for heat to travel across a void.

Why Conduction and Convection Fail in a Vacuum

To understand why radiation is the only answer, it's crucial to first understand why the other two methods of heat transfer are impossible in a vacuum.

The Role of Particles in Conduction

Conduction is the transfer of heat through direct contact. In solids, it's the vibration of atoms in a lattice; in fluids, it's collisions between molecules.

Without particles to collide or vibrate against each other, there is no medium through which conductive heat transfer can occur. A vacuum, by its nature, eliminates this pathway.

The Requirement of a Fluid for Convection

Convection is the transfer of heat through the bulk movement of a fluid (a liquid or gas). A warmer, less dense portion of the fluid rises, and a cooler, denser portion sinks, creating a current that circulates heat.

Since a vacuum contains no fluid, there is nothing to create a convective current. This mode of transfer is therefore completely absent.

How Thermal Radiation Works

Radiation is fundamentally different. It does not rely on matter to carry energy from one place to another.

Heat as Electromagnetic Waves

Every object with a temperature above absolute zero (-273.15°C or 0K) emits thermal energy in the form of electromagnetic radiation. For most objects we encounter, this radiation is primarily in the infrared spectrum, which is invisible to the human eye but can be felt as heat.

No Medium Required

Just as light from the sun travels across the vacuum of space to reach Earth, thermal radiation travels unimpeded through a vacuum. The energy is carried within the waves themselves. When these waves strike another object, the energy is absorbed, causing the object's particles to vibrate more rapidly, which we measure as an increase in temperature.

The Importance of Surface Properties

The rate of radiative heat transfer is heavily influenced by an object's surface. The key property is emissivity, a measure of how effectively a surface emits thermal radiation, on a scale from 0 to 1.

A matte black surface has a high emissivity (near 1), meaning it is very effective at both radiating and absorbing heat. A shiny, polished silver surface has a very low emissivity (near 0), making it a poor radiator and a poor absorber (a good reflector) of heat.

Understanding the Practical Implications

This principle is not just theoretical; it dictates the design of many critical technologies.

The Everyday Vacuum Flask (Thermos)

A vacuum flask is a perfect example. It consists of two walls separated by a vacuum.

- The vacuum stops heat transfer by conduction and convection.

- The walls are coated with a reflective, metallic layer (low emissivity) to stop heat transfer by radiation.

This three-pronged defense against heat transfer is what keeps hot liquids hot and cold liquids cold.

Real-World "Imperfect" Vacuums

In practical applications, like industrial vacuum furnaces or scientific chambers, a "perfect" vacuum is unattainable. There are always some residual gas molecules.

In these partial vacuums, a minuscule amount of conduction and convection can still occur. However, especially at high temperatures where radiation is much stronger, these effects are often negligible. Radiation remains the dominant, and often the only significant, mode of heat transfer.

Spacecraft Thermal Management

In the near-perfect vacuum of space, radiation is the only way a spacecraft can release the heat generated by its electronics or absorb warmth from the sun. Engineers use specialized high-emissivity radiators (to get rid of heat) and highly reflective multi-layer insulation (to block solar radiation).

Making the Right Choice for Your Goal

Controlling heat transfer in a vacuum environment comes down to managing radiation by carefully selecting surface materials and finishes.

- If your primary focus is insulation (blocking heat): Use highly reflective surfaces with low emissivity, like polished metal or specific coatings, to minimize both the absorption and emission of radiative heat.

- If your primary focus is heating an object: Use a surface with high emissivity, such as a matte black coating, to ensure the object efficiently absorbs incoming radiant energy.

- If your primary focus is cooling an object: Use a high-emissivity surface to allow the object to radiate its internal heat away into its surroundings as effectively as possible.

Mastering the properties of thermal radiation is the key to controlling temperature in any vacuum environment.

Summary Table:

| Heat Transfer Method | Possible in a Vacuum? | Reason |

|---|---|---|

| Conduction | No | Requires direct contact between particles/matter. |

| Convection | No | Requires a fluid (liquid or gas) to circulate. |

| Radiation | Yes | Transfers energy as electromagnetic waves, needing no medium. |

Need precise temperature control in your vacuum processes? KINTEK specializes in lab equipment and consumables designed to master thermal radiation. Whether you require efficient heating, cooling, or insulation solutions for your vacuum furnace or chamber, our expertise ensures optimal performance for your laboratory. Contact our experts today to discuss how we can enhance your thermal management!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What are vacuum furnace parts? A Guide to the Core Systems for Precision Heat Treatment

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- At what temperature does molybdenum evaporate? Understanding Its High-Temperature Limits

- Why is high-temperature vacuum heat treatment critical for Cr-Ni steel? Optimize Strength & Surface Integrity

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials