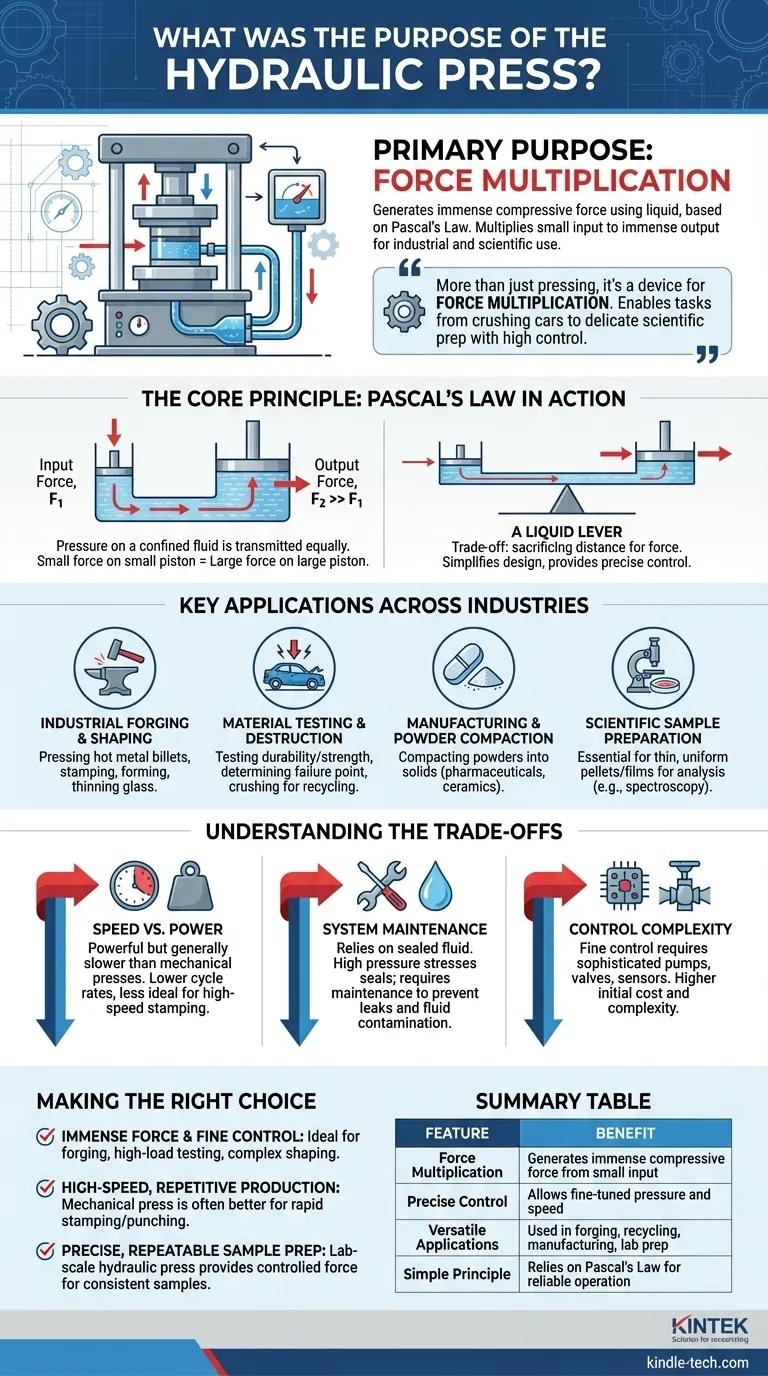

The primary purpose of a hydraulic press is to generate a powerful compressive force by using a liquid. It operates on a fundamental physics principle that allows it to multiply a small input force into an immense output force, making it a cornerstone of modern industry and scientific research.

The hydraulic press isn't simply a machine for pressing things; it's a device for force multiplication. By exploiting the behavior of a confined fluid, it enables tasks ranging from crushing cars to preparing delicate scientific samples, all with a level of control that purely mechanical systems struggle to achieve.

The Core Principle: How Force is Multiplied

At the heart of every hydraulic press is a simple yet profound concept that transforms a small effort into a massive output. Understanding this principle reveals why this machine is so effective.

Pascal's Law in Action

A hydraulic press works because of Pascal's Law, which states that pressure applied to a confined fluid is transmitted equally in all directions.

The system uses two pistons of different sizes in a sealed, fluid-filled container. When a small force is applied to the smaller piston, it creates pressure in the fluid. This same pressure then acts on the much larger surface area of the second piston, generating a proportionally larger output force.

A Liquid Lever

Think of the hydraulic fluid as a liquid lever. A small push over a long distance on the small piston results in a massive, powerful push over a short distance on the large piston.

This trade-off—sacrificing distance for force—is what allows the machine to shape solid metal and perform other high-force tasks with relative ease.

Simplicity and Control

This hydraulic system replaces more complex mechanical components like cranks, gears, or jackscrews. This not only simplifies the design but gives operators precise control over the applied force and speed, which is crucial for creating unique or intricate shapes during forging.

Key Applications Across Industries

The versatility of the hydraulic press means it is used in a vast range of applications, from heavy manufacturing to delicate laboratory work.

Industrial Forging and Shaping

This is a primary use case. The immense, controlled force is ideal for pressing hot billets or ingots of metal into desired shapes, a process known as forging. It is also used to stamp and form sheets of metal or thin out materials like glass.

Material Testing and Destruction

Engineers use hydraulic presses to test the durability and strength of materials and components. By applying a measured compressive force, they can determine the exact point of failure. On a larger scale, this same power is used to crush vehicles for recycling.

Manufacturing and Powder Compaction

In many manufacturing processes, a hydraulic press is used to compact powders into a solid form, such as in the creation of pharmaceuticals or ceramics.

Scientific Sample Preparation

In laboratory settings, a smaller hydraulic press is essential for sample preparation. Scientists use it to press materials into thin, uniform pellets or films, which is a critical step for analysis with techniques like spectroscopy.

Understanding the Trade-offs

While incredibly powerful, the hydraulic press is not the solution for every problem. Its design comes with inherent characteristics that create specific trade-offs.

Speed vs. Power

Hydraulic systems are masters of force but are generally slower than mechanical presses. The time it takes to move fluid and build pressure means their cycle rates are lower, making them less ideal for high-speed, repetitive stamping operations.

System Maintenance

The system's effectiveness depends entirely on a sealed, contained fluid. High pressures put stress on seals and hoses, which require regular maintenance to prevent leaks. Any air or contamination in the hydraulic fluid can severely degrade performance.

Control Complexity

While offering fine control, achieving that control requires a sophisticated system of pumps, valves, and sensors. This can add to the initial cost and complexity compared to simpler mechanical alternatives.

Making the Right Choice for Your Goal

The decision to use a hydraulic press depends entirely on the specific requirements of the task at hand.

- If your primary focus is immense force and fine control: The hydraulic press is the superior choice for forging, high-load material testing, or shaping complex parts.

- If your primary focus is high-speed, repetitive production: A mechanical press is often better suited for rapid stamping or punching operations where cycle time is critical.

- If your primary focus is precise, repeatable sample preparation: A laboratory-scale hydraulic press provides the controlled force necessary for creating consistent scientific samples.

Ultimately, the hydraulic press is a remarkable machine that demonstrates how a basic law of physics can be engineered to shape, test, and build our world.

Summary Table:

| Feature | Benefit |

|---|---|

| Force Multiplication | Generates immense compressive force from a small input |

| Precise Control | Allows fine-tuned pressure and speed for shaping and testing |

| Versatile Applications | Used in forging, recycling, manufacturing, and lab sample prep |

| Simple Principle | Relies on Pascal's Law for reliable, powerful operation |

Need precise, high-force solutions for your lab or production line? KINTEK specializes in lab equipment and consumables, including hydraulic presses designed for material testing and sample preparation. Our expertise ensures you get the right equipment for your specific needs, enhancing efficiency and accuracy in your work. Contact us today to discuss how we can support your laboratory or industrial requirements!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy