While hydraulic and mechanical presses dominate the industrial landscape, the hydraulic press is arguably the most common type across a vast range of manufacturing sectors. This is due to its unmatched versatility, ability to deliver immense and controllable force at any point in its stroke, and inherent simplicity of operation. Its design allows it to be adapted for everything from delicate assembly work to massive forging operations.

The core issue is not simply identifying the "most common" press, but understanding the fundamental choice between the two industry workhorses: the hydraulic press, which excels at delivering controlled force, and the mechanical press, which excels at delivering speed and repeatable precision.

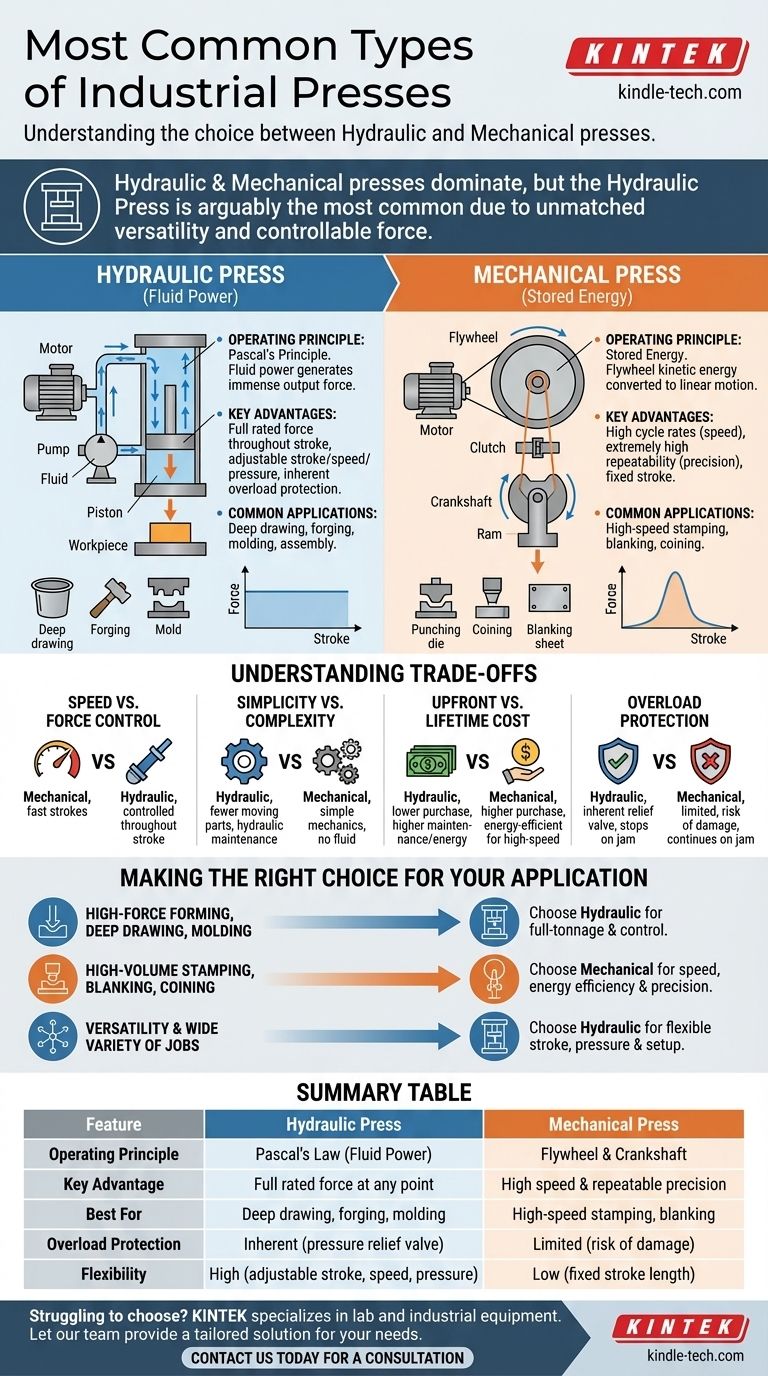

The Two Pillars of Industrial Presses

In modern manufacturing, the vast majority of press work is accomplished by one of two designs: hydraulic or mechanical. Though they both apply force to shape or assemble materials, their operating principles are fundamentally different, making them suitable for distinct tasks.

Understanding the Hydraulic Press

A hydraulic press operates on the foundation of Pascal's Principle. A force applied to a confined fluid is transmitted undiminished throughout the fluid.

How It Works: Fluid Power A motor drives a pump that pressurizes hydraulic fluid (typically oil). This pressurized fluid acts on a piston within a cylinder, generating a massive output force. Think of it as a highly leveraged system where a small pump can generate tons of force.

Key Advantages: Force and Flexibility The primary advantage of a hydraulic press is its ability to deliver its full rated force at any point during the ram's stroke. The stroke length, speed, and pressure are all easily adjustable, offering incredible flexibility for a wide variety of jobs. They also feature built-in overload protection; a pressure relief valve simply prevents the system from exceeding its safe limit.

Common Applications Their force and control make them ideal for processes like deep drawing (forming a sheet of metal into a cup), forging, plastic molding, and assembly operations where precise, sustained pressure is required.

Understanding the Mechanical Press

A mechanical press uses a motor to spin a heavy flywheel. When the press is activated, a clutch connects the spinning flywheel to a crankshaft, which converts the rotational energy into the powerful, linear motion of the ram.

How It Works: Stored Energy The system's power comes from the kinetic energy stored in the massive flywheel. The press delivers maximum force only at the very bottom of its stroke, as this is where the mechanical linkage has the most leverage.

Key Advantages: Speed and Precision Mechanical presses are champions of speed and consistency. They can achieve very high cycle rates, making them perfect for high-volume production. Because the stroke length is fixed by the crankshaft's geometry, they offer extremely high repeatability, which is critical for precision tasks.

Common Applications You will find mechanical presses dominating industries that require high-speed stamping, blanking (punching shapes from a sheet), and coining, where millions of identical parts must be produced quickly and efficiently.

Understanding the Trade-offs: Hydraulic vs. Mechanical

Choosing between these two press types involves a clear set of engineering and economic trade-offs. There is no single "best" press, only the best press for a specific application.

Speed vs. Force Control

A mechanical press is significantly faster in terms of strokes per minute for high-volume work. However, a hydraulic press offers complete control over the force throughout the entire stroke, which is a critical requirement for many forming operations.

Simplicity vs. Complexity

Hydraulic presses are mechanically simple, with fewer moving parts than a mechanical press. However, their hydraulic systems (pumps, valves, seals, and fluid) can add complexity and require specialized maintenance to prevent leaks and ensure fluid cleanliness.

Upfront Cost vs. Lifetime Cost

While costs vary greatly by size, hydraulic presses can sometimes have a lower initial purchase price. However, their energy consumption can be higher, and hydraulic component maintenance can be a significant long-term operating cost. Mechanical presses, while often more expensive upfront, can be more energy-efficient for their intended high-speed tasks.

Overload Protection

This is a critical distinction. A hydraulic press is inherently protected from overload by its pressure relief valve. If a jam occurs, the system simply stops. A mechanical press, driven by momentum, will try to complete its stroke regardless of a jam, which can lead to catastrophic damage to the press itself or the expensive die.

Making the Right Choice for Your Application

Your final decision must be guided by the demands of the job.

- If your primary focus is high-force forming, deep drawing, or molding: A hydraulic press is your best choice for its full-tonnage capability and control throughout the stroke.

- If your primary focus is high-volume stamping, blanking, or coining: A mechanical press is superior due to its unmatched speed, energy efficiency at rate, and repeatable precision.

- If your primary focus is versatility and handling a wide variety of jobs: A hydraulic press offers more flexibility in stroke length, pressure control, and die setup.

Understanding the fundamental difference in how they generate force empowers you to select the press that functions not just as a machine, but as a direct solution to your manufacturing challenge.

Summary Table:

| Feature | Hydraulic Press | Mechanical Press |

|---|---|---|

| Operating Principle | Pascal's Law (Fluid Power) | Flywheel & Crankshaft (Mechanical Energy) |

| Key Advantage | Full rated force at any point in stroke | High speed and repeatable precision |

| Best For | Deep drawing, forging, molding, assembly | High-speed stamping, blanking, coining |

| Overload Protection | Inherent (pressure relief valve) | Limited (risk of catastrophic damage) |

| Flexibility | High (adjustable stroke, speed, pressure) | Low (fixed stroke length) |

Struggling to choose the right press for your manufacturing needs? KINTEK specializes in lab and industrial equipment, offering expert guidance to help you select the ideal hydraulic or mechanical press for your specific application—whether you need precision force control or high-speed production. Let our team provide a tailored solution to enhance your efficiency and output. Contact us today for a consultation!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why do we use KBr in FTIR? The Key to Clear, Accurate Solid Sample Analysis

- How does pressure affect hydraulic system? Mastering Force, Efficiency, and Heat

- What is the purpose of KBr pellets? Unlock Clear FTIR Analysis of Solid Samples

- What is a hydraulic press for sample preparation? Create Consistent Pellets for Reliable Analysis

- How much force can a hydraulic press exert? Understanding its immense power and design limits.