A heating element that repeatedly fails is almost always a symptom of an underlying system issue, not just a faulty part. The most common culprit is a condition known as "dry firing," where the element is energized without being fully submerged in water. Lacking water to absorb its intense heat, the element essentially burns itself out in seconds. However, mineral buildup and electrical problems are also frequent causes of premature failure.

A heating element is a simple device designed for a long life. If it fails repeatedly, the root cause is almost always its operating environment—specifically, a lack of water contact, excessive mineral buildup, or an improper electrical supply.

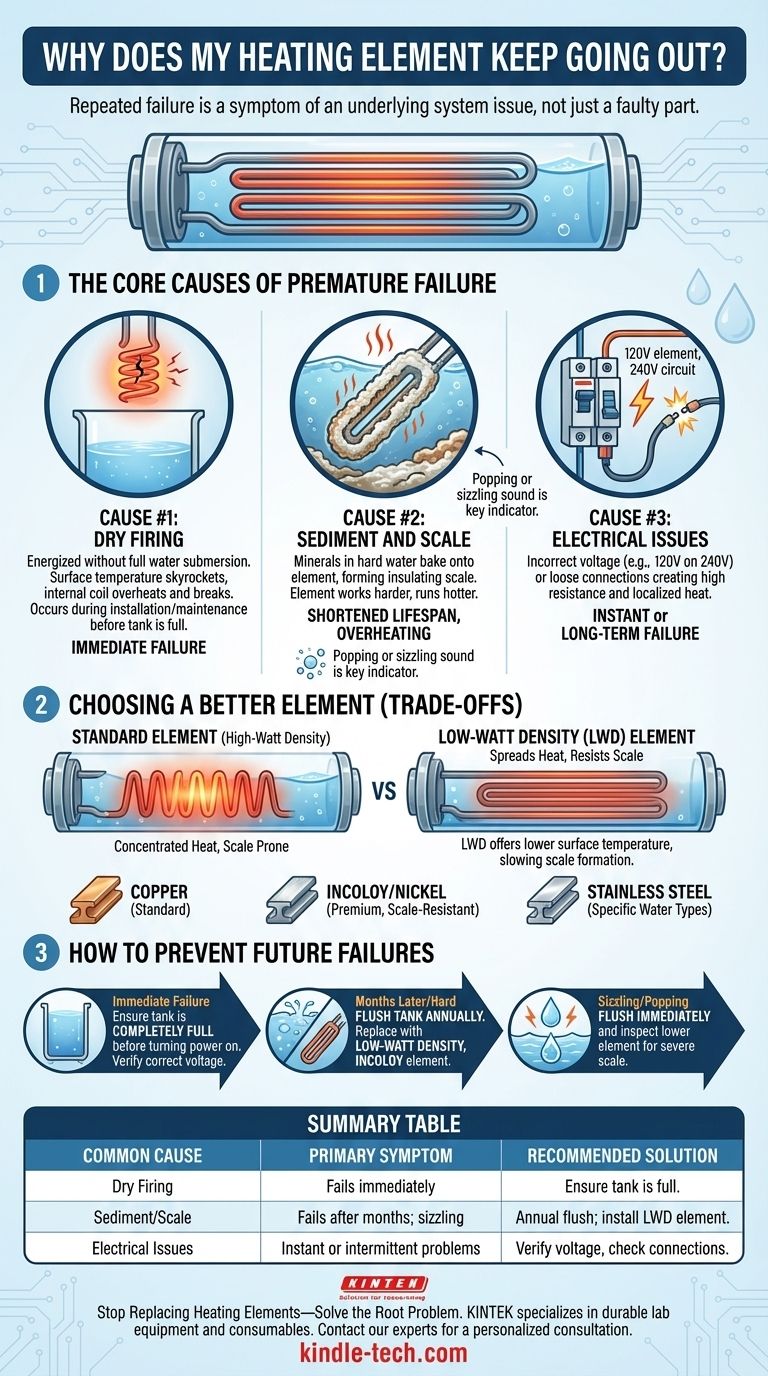

The Core Causes of Premature Element Failure

To stop replacing elements, you must first diagnose the environmental condition that is destroying them. The failure is the symptom, not the disease.

Cause #1: Dry Firing

Dry firing is the number one cause of immediate element failure. It occurs when the element is turned on while exposed to air instead of being surrounded by water.

Without water to dissipate the energy, the element's surface temperature skyrockets almost instantly, causing the internal coil to overheat, melt, and break the circuit.

This typically happens during installation or maintenance. If you turn the circuit breaker on before the water heater tank has been completely filled, the upper element will dry fire and be destroyed.

Cause #2: Sediment and Scale Buildup

If an element works for weeks or months before failing, the problem is likely sediment and scale. This is especially common in areas with hard water.

Minerals like calcium and magnesium naturally present in the water bake onto the element's surface, forming a hard, crusty layer of scale.

This scale acts as an insulator, forcing the element to work much harder and run hotter to heat the surrounding water. This constant state of overheating dramatically shortens its lifespan, eventually causing it to burn out. A popping or sizzling sound from the tank is a key indicator of heavy sediment buildup.

Cause #3: Electrical Issues

An incorrect electrical supply can cause both immediate and long-term failures.

A common mistake is installing a 120-volt element on a 240-volt circuit. This overloads the element with double the intended voltage, causing it to burn out almost instantly.

Conversely, loose wire connections at the element's terminals or the thermostat can create high electrical resistance. This resistance generates intense, localized heat, which can damage the element's seal or the wiring itself over time, leading to failure.

Understanding the Trade-offs: Choosing a Better Element

Not all heating elements are created equal. If your elements are failing due to hard water, you can make a strategic choice to extend the life of the next one.

Standard vs. Low-Watt Density Elements

A low-watt density (LWD) element is a significant upgrade for tanks prone to scale buildup. It has a much larger surface area than a standard element of the same wattage.

This spreads the heat over a wider area, reducing the intensity at any single point. This lower surface temperature makes it much harder for minerals to bake on, drastically slowing the formation of scale and extending the element's life.

Element Material Matters

The element's sheath material also plays a role in its longevity.

- Copper: This is the standard, inexpensive option suitable for most water conditions.

- Incoloy/Nickel Alloys: These premium alloys have a slicker surface and superior resistance to high temperatures. They are the best choice for fighting scale buildup in hard water.

- Stainless Steel: Best for specific water types, like deionized water, but less effective against scale than Incoloy.

How to Prevent Future Element Failures

Stop the cycle of replacement by addressing the root cause of the failure. Your approach should be determined by the symptoms you're observing.

- If an element fails immediately after installation: You have a dry-fire or voltage problem. Ensure the tank is completely full of water before you turn the circuit breaker back on, and verify the element's voltage rating matches your circuit.

- If an element fails after several months in a hard-water area: You have a scale problem. Flush your water heater annually to remove sediment and replace the failed part with a low-watt density, Incoloy-sheathed element.

- If you hear sizzling or popping from the tank: This is a clear sign of severe sediment buildup. Flush the tank immediately and inspect the lower element, as it's likely encased in scale and close to failure.

By addressing the element's environment, you shift from repeatedly fixing the symptom to solving the core problem.

Summary Table:

| Common Cause of Failure | Primary Symptom | Recommended Solution |

|---|---|---|

| Dry Firing | Fails immediately after installation | Ensure tank is full before turning on power |

| Sediment/Scale Buildup | Fails after months; sizzling/popping sounds | Annual flushing; install low-watt density element |

| Electrical Issues | Instant failure or intermittent problems | Verify correct voltage and check for loose connections |

Stop Replacing Heating Elements—Solve the Root Problem

Tired of the endless cycle of heating element failure? KINTEK specializes in the durable lab equipment and consumables your operations depend on. Whether you're battling hard water scale with our premium Incoloy-sheathed elements or need expert advice on preventing dry firing, we provide the reliable solutions and technical support to keep your systems running smoothly and efficiently.

Upgrade your lab's reliability today. Contact our experts now for a personalized consultation and extend the life of your critical heating components.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How does an armored K-type thermocouple ensure the repeatability of experimental results? Achieve Precision in Nitriding

- Why are K-type thermocouples shielded with niobium alloy tubes used? Ensure Accurate Microwave Pyrolysis Control

- Can heating elements overheat? Prevent Burnout and Ensure Safe Operation

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What are the causes of failure of heating elements? Prevent Downtime with Proper Operation

- How effective is electrical resistance heating? It's 100% efficient at the point of use.

- What is the most accurate temperature sensor? Why RTDs Lead in Precision and Stability

- What are the properties of a heating element? A Guide to Performance, Lifespan & Cost