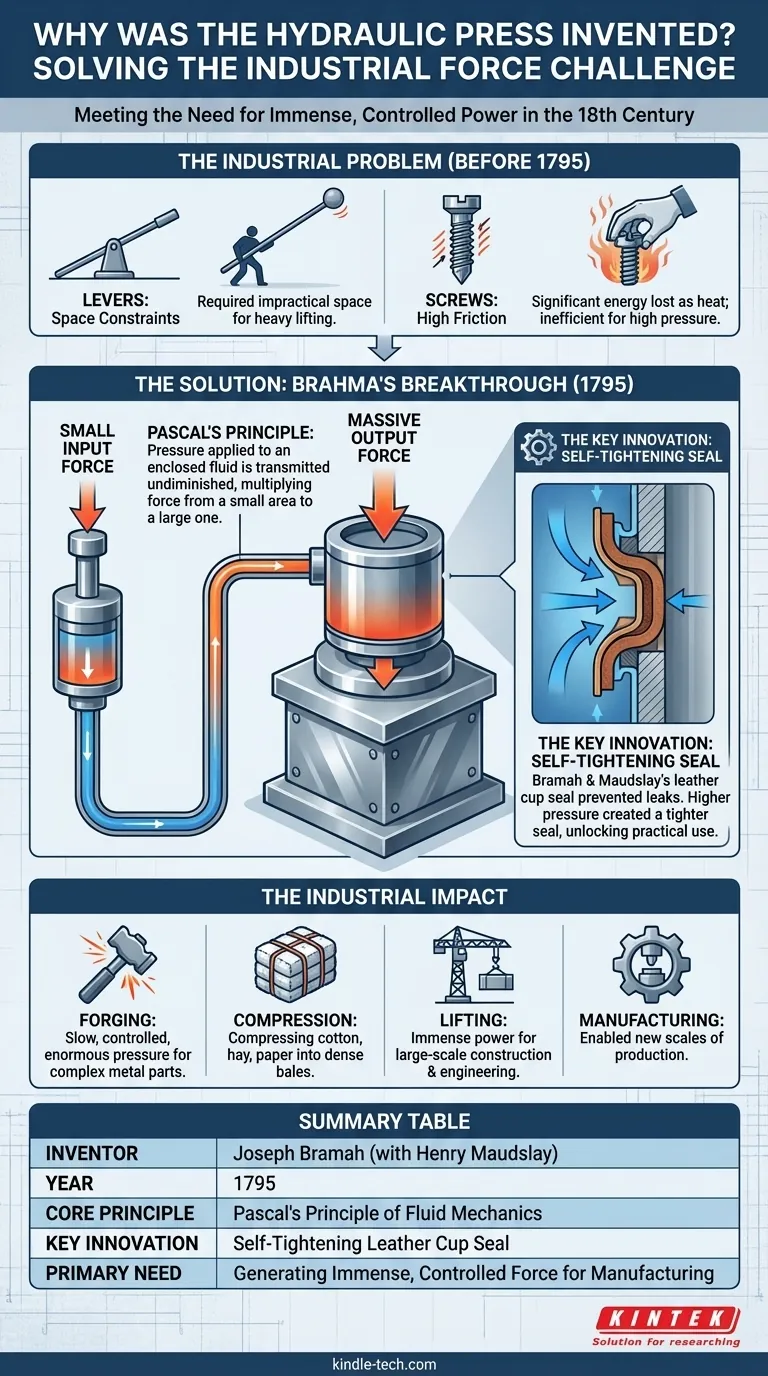

The hydraulic press was invented to solve a fundamental problem of the Industrial Revolution: the need to generate and control immense amounts of force far beyond what was possible with simple machines like levers or screws. It was created by Joseph Bramah in 1795 to provide a practical way to multiply a small, manageable input force into a massive output force for industrial tasks.

The invention of the hydraulic press was not about discovering a new law of physics, but about solving the critical engineering challenge of applying a known one—Pascal's Principle—to meet the new, large-scale demands for force in manufacturing, forging, and lifting.

The Industrial Need for Greater Force

During the late 18th century, the Industrial Revolution created problems that traditional tools could not solve. Factories needed to lift heavier objects, compress materials more tightly, and shape metal with greater power than ever before.

The Limits of Levers and Screws

Simple machines like levers could multiply force, but they required an enormous amount of space to achieve significant gains. A lever long enough to lift tons of weight would be impractical in a factory setting.

Likewise, screws (as used in screw presses) could generate high forces, but they suffered from immense friction. A large portion of the energy put into turning the screw was lost as heat, making them inefficient for very high-pressure applications.

The Scientific and Engineering Breakthrough

The solution came from combining a 150-year-old scientific principle with a new engineering innovation. This combination turned a theoretical concept into one of the most powerful tools of the industrial age.

Applying Pascal's Principle

The inventor, Joseph Bramah, based his press on Pascal's Principle, a concept of fluid mechanics established by Blaise Pascal in the 1600s.

This principle states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In a hydraulic press, this means a small force applied to a small piston creates pressure in a fluid. This pressure then acts on a much larger piston, multiplying the original force significantly.

The Real Innovation: Solving the Seal

The scientific principle was well-known, but no one had been able to build a working machine because the fluid would leak around the piston under high pressure.

Bramah's true genius, with the help of his employee Henry Maudslay, was in inventing a self-tightening seal. This leather cup seal was designed so that the higher the fluid pressure, the more tightly it pressed against the cylinder wall, preventing leaks. This was the key that unlocked the practical application of Pascal's law.

The Impact of the New Machine

The Bramah Press, as it was known, was a revolutionary device that transformed industrial capabilities.

Forging and Manufacturing

The press could exert slow, controlled, and enormous pressure, making it ideal for forging metal parts. It allowed for the creation of larger and more complex components than was possible with hammering.

Compression and Lifting

Industries used the press to compress materials like cotton, hay, and paper into dense, small bales for easier transport. Its immense lifting power also made it invaluable for large-scale construction and engineering projects.

Why It Took So Long to Invent

The core challenge was not in understanding the theory but in overcoming a practical engineering hurdle.

The Sealing Problem

For over a century, Pascal's principle remained a concept in physics textbooks. The lack of a reliable method to contain high-pressure fluids was the primary barrier to its use in a machine.

The Need for Precision Machining

Creating a piston and cylinder that were smooth and precise enough to even attempt a seal was a significant challenge. The advancements in machining and metalworking during the Industrial Revolution, pioneered by people like Maudslay, were necessary prerequisites for the press's invention.

Applying This Understanding

Understanding the story of the hydraulic press provides a clear model for how innovation happens.

- If your primary focus is on invention: Recognize that major breakthroughs often come from applying an existing scientific principle to a pressing real-world problem, with the final piece being a practical engineering solution.

- If your primary focus is on industrial history: The hydraulic press is a perfect example of a "foundational technology" that enabled countless other advancements by removing a fundamental physical limitation.

- If your primary focus is on engineering: The self-tightening seal demonstrates that the "elegant" solution is often one that uses the problem itself (high pressure) to create the solution (a tighter seal).

The hydraulic press was invented because industry needed more force, and its creation hinged on solving a single, critical engineering detail that had stumped thinkers for generations.

Summary Table:

| Key Element | Description |

|---|---|

| Inventor | Joseph Bramah (with Henry Maudslay) |

| Year | 1795 |

| Core Principle | Pascal's Principle of fluid mechanics |

| Key Innovation | The self-tightening leather cup seal |

| Primary Industrial Need | Generating immense, controlled force for manufacturing |

Need robust and reliable force application in your lab or production process? The story of the hydraulic press shows how a single engineering innovation can unlock immense potential. At KINTEK, we specialize in providing high-quality lab equipment and consumables that solve critical challenges for laboratories. Whether you need precise compression, efficient material handling, or durable machinery, our solutions are designed to enhance your operational capabilities. Contact us today to discuss how KINTEK can empower your work!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy