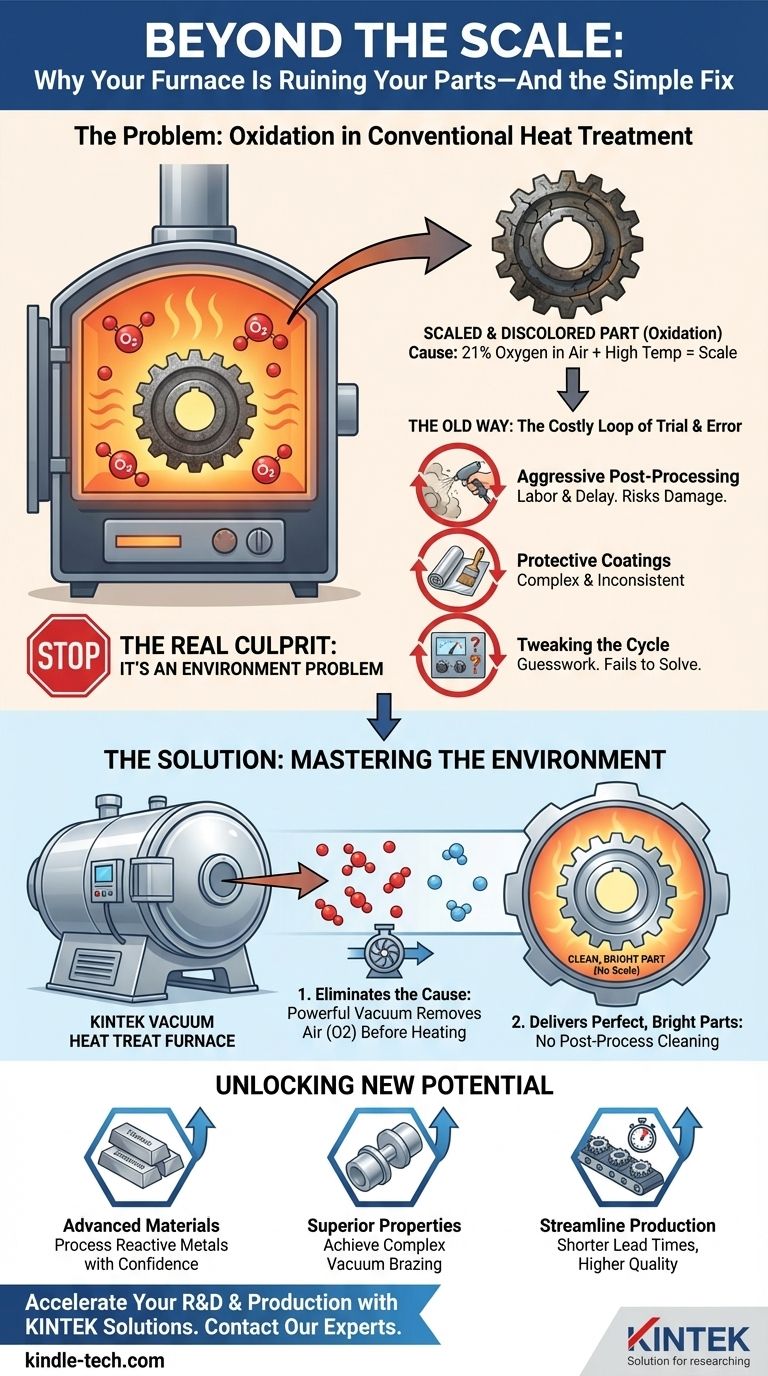

It’s a scenario every metallurgist and engineer dreads. You pull a meticulously machined, high-value component from your furnace after a long heat treatment cycle. Instead of the pristine, strong part you expected, it’s covered in a dark, flaky layer of scale. The critical surface finish is ruined, the precise dimensions may be compromised, and another cycle of costly, time-consuming rework begins.

If this sounds familiar, you're not alone.

Sound Familiar? The High Cost of a "Simple" Heat Treatment

For labs and production facilities worldwide, dealing with oxidation is a chronic headache. When parts emerge scaled and discolored, a familiar, frustrating process kicks in.

Many teams get caught in a loop of trial and error, attempting to solve the problem with superficial fixes:

- Aggressive Post-Processing: Hours are spent on sandblasting, grinding, or chemical stripping to remove the oxide layer. This not only adds significant labor costs and project delays but also risks damaging the part's dimensions and surface integrity.

- Protective Coatings: Applying anti-scale compounds or using foil wraps adds complexity and material cost to the process, often with inconsistent and unreliable results.

- "Tweaking" the Cycle: You might try adjusting the temperature or soaking time, hoping to find a magic window. But this is just guesswork, as it fails to address the fundamental issue.

These struggles aren't just technical annoyances; they have serious business consequences. Wasted materials drive up costs, project timelines are derailed by rework, and inconsistent product quality can damage your reputation. For R&D teams, it means unreliable data and a slower path to innovation.

The Real Culprit: Why Heat Isn't the Enemy

After countless failed attempts, it's natural to blame the furnace or the heating process itself. But what if the problem isn't the heat at all? What if the real culprit is something we take for granted: the air inside the furnace?

The science is remarkably simple. At high temperatures, most metals are highly reactive. The oxygen in the air—which makes up about 21% of the atmosphere in a conventional furnace—eagerly attacks the hot metal surface. This chemical reaction is called oxidation, and the flaky, discolored scale is its result.

This is the critical insight: Your problem isn't a heating problem; it's an environment problem.

This is precisely why the common "solutions" fail.

- Sandblasting and cleaning only treat the symptom (the scale) after the damage is already done.

- Tweaking the temperature doesn't remove the oxygen, so the reaction still occurs, just perhaps at a different rate.

To truly prevent oxidation, you don't need a better cleaning method; you need a better environment. You need to remove the oxygen before you apply the heat.

The Solution: Mastering the Environment, Not Just the Temperature

To solve the problem at its root, you need a tool specifically designed to control the processing atmosphere. This is the fundamental purpose of a vacuum heat treat furnace.

It's not just a "furnace without air." It is a precision system engineered to achieve one primary goal: create a chemically non-reactive environment. KINTEK's vacuum furnaces are the embodiment of this solution-focused design. Here's how they directly address the core problem:

- Eliminates the Cause: Before the heating cycle even begins, a powerful vacuum system removes the atmosphere—and virtually all the reactive oxygen—from the sealed chamber. By taking the "fuel" for oxidation out of the equation, the reaction is prevented from ever starting.

- Delivers Perfect, Bright Parts: Because oxidation is eliminated, your parts emerge from the furnace with the same clean, bright finish they went in with. The entire step of post-process cleaning is removed from your workflow, saving immense time and labor.

- Ensures Unmatched Repeatability: With precise digital control over the vacuum level, heating rates, and inert gas quenching, the entire process is meticulously managed. This removes the guesswork and ensures that you get the exact same metallurgical properties—batch after batch.

A KINTEK vacuum furnace isn't just another piece of equipment; it's the result of understanding the fundamental physics of the problem and engineering the direct solution.

From Problem-Solving to Unlocking New Potential

Once you are no longer fighting the daily battle against oxidation, you can focus on what really matters: innovation and performance. Eliminating this chronic issue doesn't just fix a problem; it unlocks entirely new capabilities for your team.

- Work with Advanced Materials: You can now confidently process highly reactive metals like titanium, zirconium, and refractory metals without fear of contamination, opening doors to aerospace, medical, and other high-performance applications.

- Achieve Superior Properties: With a pure environment, you can perform complex processes like vacuum brazing, creating incredibly strong and clean joints that are impossible in a conventional furnace.

- Accelerate Your R&D Cycle: When your results are clean and predictable every time, you can trust your data. This means fewer re-runs, faster material validation, and a quicker path from concept to commercialization.

- Streamline Your Production: By removing the entire post-processing stage, you can radically shorten your lead times, increase throughput, and deliver higher quality products to your customers faster.

Solving the oxidation problem is the first step. The real goal is to accelerate your projects, improve your product's reliability, and out-innovate the competition. Our team of specialists understands both the science of vacuum heat treatment and the business pressures you face. Let's discuss your specific challenges and how the right equipment can help you achieve your most ambitious goals. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vertical Laboratory Tube Furnace

Related Articles

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Beyond Heat: Mastering Material Purity in the Controlled Void of a Vacuum Furnace

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity