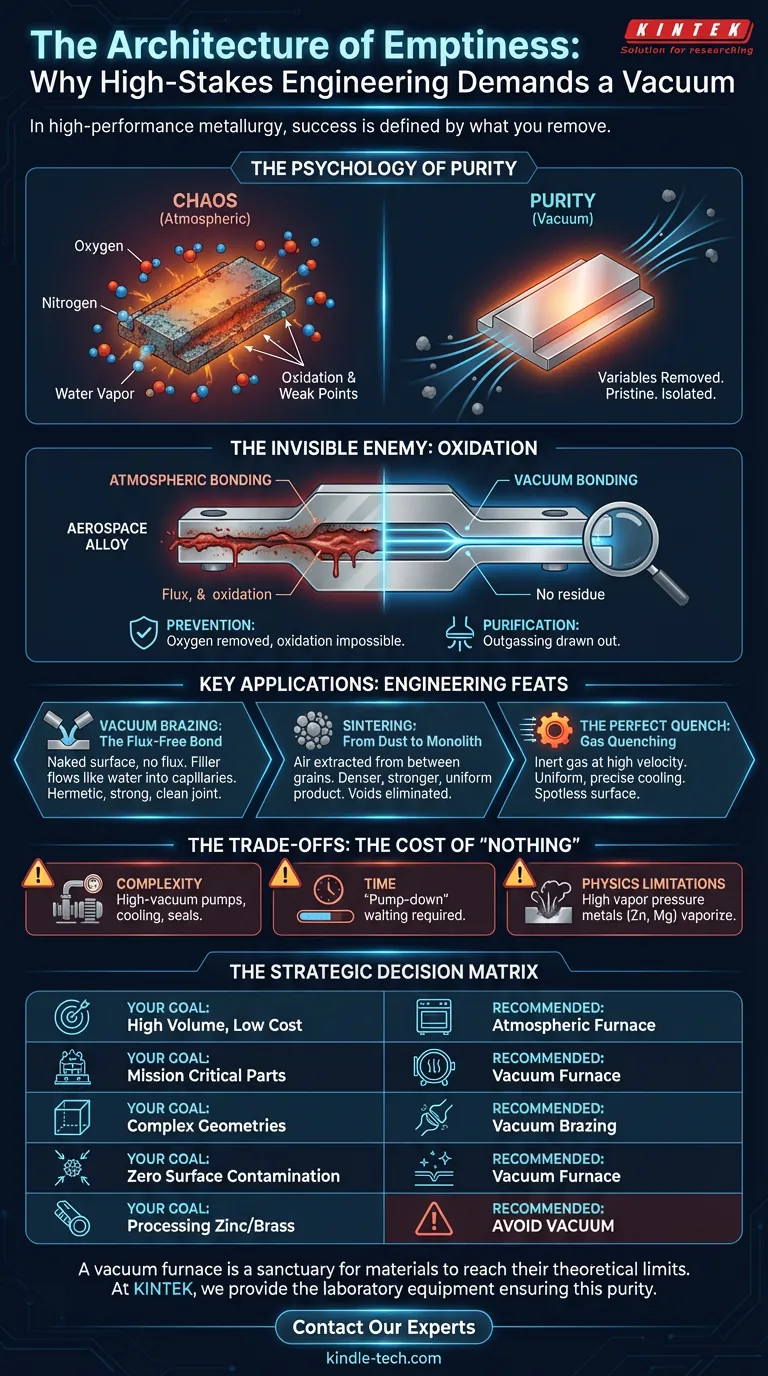

The Psychology of Purity

In engineering, we often focus on what we add to a process. We add heat. We add pressure. We add complex alloys to create stronger materials.

But in the realm of high-performance metallurgy, success is often defined by what you remove.

When you heat a metal in a standard room, you are subjecting it to a chaotic chemical attack. Oxygen, nitrogen, and water vapor are relentless opportunists. At high temperatures, they rush to bond with the metal surface, creating oxide scales and weak points.

This is where the vacuum furnace enters the story. It is not merely a tool for heating; it is a mechanism for isolation. By creating a void, we remove the variables that cause failure.

At KINTEK, we understand that for our clients in aerospace and medical manufacturing, "good enough" is indistinguishable from "failed." The vacuum furnace is the heavy artillery against imperfection.

The Invisible Enemy: Oxidation

Imagine you are trying to bond two pieces of aerospace-grade alloy.

In an atmospheric furnace, oxygen molecules immediately form a barrier—a "skin"—on the metal. To break through, you need chemical fluxes (cleaning agents). It works, but it is messy, and it leaves behind microscopic residues.

In a vacuum furnace, that enemy is evicted before the battle begins.

By pumping the chamber down to a deep vacuum, we achieve two things:

- Prevention: Oxygen is removed, so oxidation is chemically impossible. The metal remains bright and pristine.

- Purification: The low pressure encourages the metal to "exhale." Trapped gases within the material (outgassing) are drawn out and pumped away.

Key Applications: The Romance of the Process

When you remove the atmosphere, you change the rules of physics. This allows for manufacturing feats that seem almost impossible in open air.

1. Vacuum Brazing: The Flux-Free Bond

Brazing is the art of joining metals using a molten filler.

- The Atmospheric Problem: You need aggressive flux to dissolve surface oxides so the filler can flow.

- The Vacuum Solution: Because the surface is naked and oxide-free, the filler metal flows like water into the tightest capillaries.

- The Result: A hermetically sealed, incredibly strong joint without a trace of corrosive residue. This is the gold standard for aircraft engines and medical implants.

2. Sintering: From Dust to Monolith

Sintering fuses powder particles into solid objects.

If you trap air between those particles, you create voids. Voids are cracks waiting to happen. A vacuum furnace extracts the air from between the grains of powder, resulting in a product that is denser, stronger, and more uniform.

3. The Perfect Quench

Heat treating requires heating a part and then cooling it rapidly (quenching) to lock in hardness.

Vacuum furnaces utilize gas quenching. Instead of plunging a hot part into messy oil or water, the furnace backfills the chamber with inert gas (like nitrogen) at high velocity. The cooling is uniform, precise, and leaves the surface spotless.

The Trade-offs: The Cost of "Nothing"

If vacuum furnaces are so superior, why isn't every oven a vacuum furnace?

Because creating "nothing" is expensive.

- Complexity: It requires high-vacuum pumps, water cooling jackets, and leak-proof seals.

- Time: You cannot just turn it on. You must wait for the "pump-down"—the evacuation of air—before heat is applied.

- Physics Limitations: Some metals, like Zinc or Magnesium, have high vapor pressures. If you put them in a vacuum furnace, they won't just melt; they will vaporize, coating the inside of your expensive equipment in metal dust.

The Strategic Decision

Choosing a vacuum furnace is a shift in mindset. You are prioritizing control over speed.

You choose this technology when the cost of failure exceeds the cost of the equipment.

Quick Decision Matrix

| Your Goal | The Recommended Path |

|---|---|

| High Volume, Low Cost | Atmospheric Furnace (Standard) |

| Mission Critical Parts | Vacuum Furnace |

| Complex Geometries | Vacuum Brazing |

| Zero Surface Contamination | Vacuum Furnace |

| Processing Zinc/Brass | Avoid Vacuum (Vaporization Risk) |

Conclusion: The Vessel for Perfection

A vacuum furnace is a testament to the engineer’s desire for absolute predictability. It is a sanctuary where materials can reach their theoretical limits without the interference of the outside world.

Whether you are sintering high-performance ceramics or brazing complex medical assemblies, the quality of your output is dictated by the purity of your environment.

At KINTEK, we provide the laboratory equipment that ensures this purity. Our vacuum furnaces are designed for those who understand that the most important ingredient in material science is often the absence of everything else.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

Related Articles

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- More Than Nothing: The Art of Partial Pressure in High-Temperature Furnaces

- Why Your High-Temperature Processes Fail: The Hidden Enemy in Your Vacuum Furnace

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum