Oxygen is a relentless saboteur.

In the world of materials science, the moment you heat a metal, you accelerate its relationship with the air around it. Usually, this is a destructive relationship. Oxygen creates scaling. Water vapor invites decarburization. The seemingly invisible air in your lab becomes a thick, reactive soup that wants to compromise your component’s integrity.

To solve this, engineers have developed two distinct philosophies.

One attempts to manage the crowd. The other attempts to empty the room.

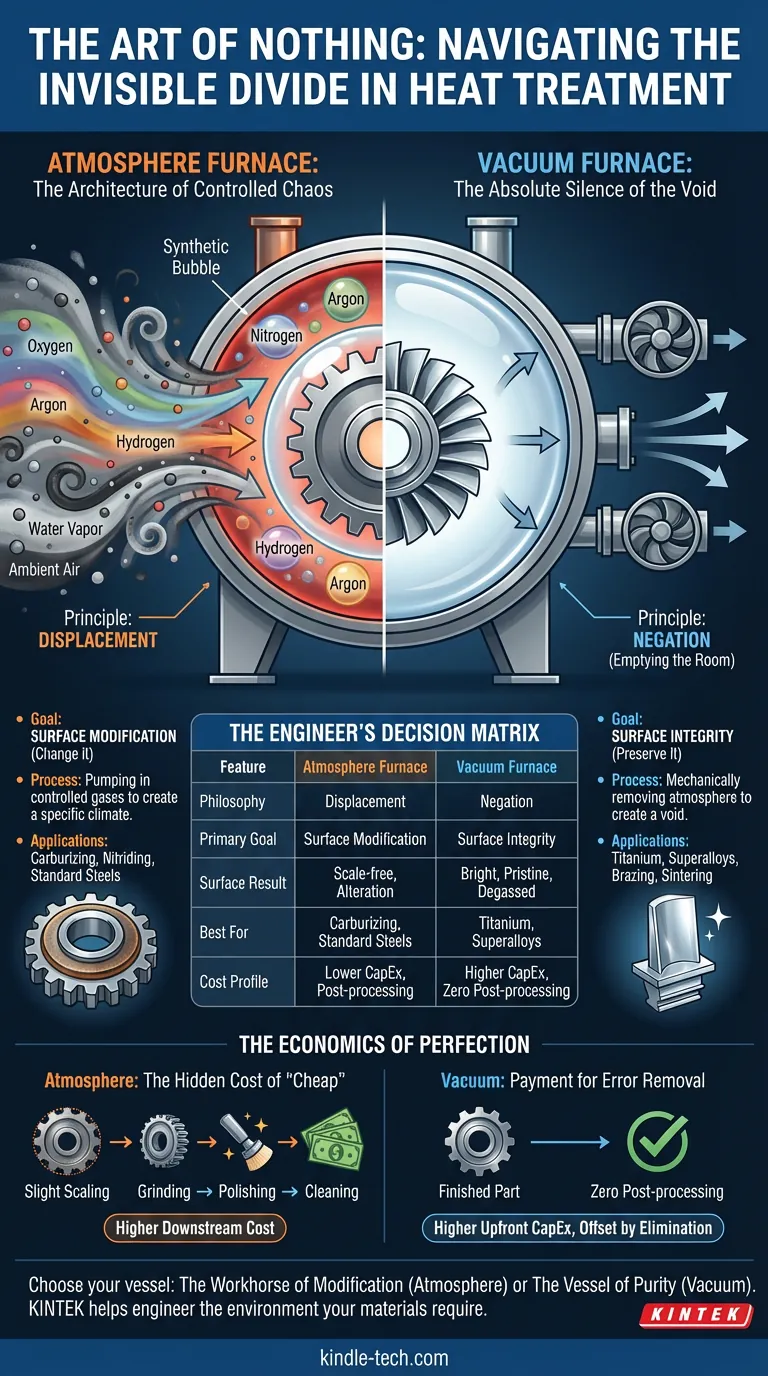

This is the fundamental divergence between the Atmosphere Furnace and the Vacuum Furnace. It is not just a difference in machinery; it is a difference in how we define purity and control.

The Architecture of Controlled Chaos

The Atmosphere Furnace operates on a principle of displacement.

If the ambient air is the enemy, the solution is to push it out and replace it with something friendly. You are not creating a void; you are engineering a specific climate.

By pumping in controlled gases—typically Nitrogen, Argon, or Hydrogen—you create a "synthetic bubble" around your material. This approach accepts that the part must be surrounded by something, so it ensures that "something" is predictable.

The Strategic Utility

Atmosphere furnaces are not just about protection; they are often about active modification. They are the tools of choice when you want to change the surface chemistry of a metal, not just preserve it.

- Carburizing: Intentionally introducing carbon to steel to harden the surface.

- Nitriding: Using nitrogen to create a tough, wear-resistant case.

However, there is a limitation. It is a statistical game. Even with high-quality gas flow, achieving 100% inertness is difficult. Trace impurities can remain. For high-volume steel processing, this is an acceptable, cost-effective trade-off.

The Absolute Silence of the Void

The Vacuum Furnace takes a more radical approach. It does not try to improve the air. It eliminates it.

When you seal the chamber and activate the pumps, you are mechanically removing the atmosphere. You are pulling out oxygen, nitrogen, and moisture until the chamber contains... nothing.

The Physics of Purity

In this void, oxidation is physically impossible because the reactants simply aren't there.

The results of vacuum processing often feel like engineering magic. Parts that go in dull and grey emerge "bright"—shiny, clean, and completely free of discoloration. The vacuum doesn't just protect; it cleans. It degasses the material, removing volatile contaminants from the metal's own structure.

This environment is non-negotiable for specific materials:

- Reactive Metals: Titanium and Zirconium, which will destroy themselves if heated in the presence of oxygen.

- Superalloys: High-performance materials used in aerospace that require zero surface compromise.

- Brazing: Where the flow of alloy requires perfectly clean surfaces to bond without flux.

The Economics of Perfection

Why doesn't every lab use a vacuum furnace?

The answer lies in the "Psychology of Good Enough."

A vacuum furnace is a complex pressure vessel. It requires sophisticated pumps, seals, and leak detection. It is an investment in absolute certainty.

An atmosphere furnace is simpler. It creates a "good enough" environment for the vast majority of standard industrial hardening and annealing tasks.

The Hidden Cost of "Cheap"

However, looking only at the upfront price tag is a mistake.

If you use an atmosphere furnace for a sensitive part, the part may come out with slight scaling. You then have to pay for:

- Grinding

- Polishing

- Cleaning

A vacuum furnace produces a finished part. The higher upfront capital cost is often offset by the elimination of these downstream cleaning steps. You are paying for the removal of error.

The Engineer’s Decision Matrix

Choosing between these two technologies is a decision about your material's final destiny.

| Feature | Atmosphere Furnace | Vacuum Furnace |

|---|---|---|

| Philosophy | Displacement: Replace bad air with good gas. | Negation: Remove all air entirely. |

| Primary Goal | Surface Modification (change it). | Surface Integrity (preserve it). |

| Surface Result | Scale-free (mostly), potential for alteration. | Bright, pristine, degassed. |

| Best For | Carburizing, Nitriding, Standard Steels. | Titanium, Superalloys, Brazing, Sintering. |

| Cost Profile | Lower CapEx, potentially higher post-processing. | Higher CapEx, zero post-processing. |

Conclusion

If your goal is to chemically alter the surface of a steel gear, the Atmosphere Furnace is your instrument. It is the workhorse of modification.

If your goal is to preserve the atomic fidelity of a titanium implant or an aerospace turbine blade, the Vacuum Furnace is your sanctuary. It is the vessel of purity.

At KINTEK, we understand that this choice defines your workflow. We do not just sell equipment; we help you engineer the environment your materials require. Whether you need the controlled chemistry of an atmosphere system or the deep silence of a high-vacuum chamber, we have the precision tools to make it happen.

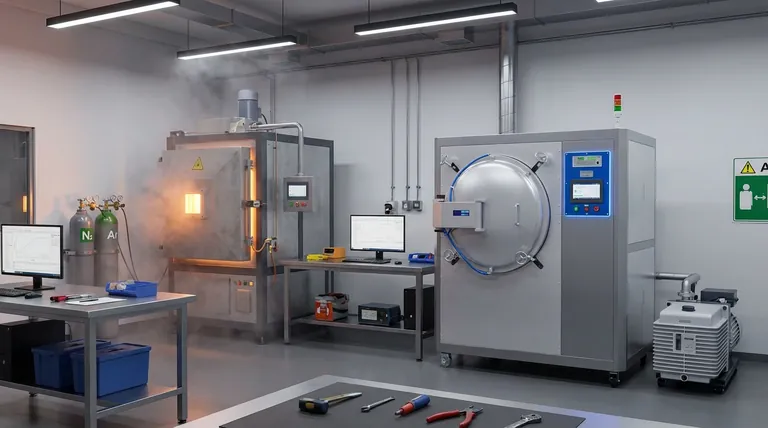

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Mesh belt controlled atmosphere furnace

Related Articles

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- Beyond Heat: Mastering Material Purity in the Controlled Void of a Vacuum Furnace

- More Than Nothing: The Art of Partial Pressure in High-Temperature Furnaces

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?