The Illusion of Safety

In high-stakes engineering, your intuition is often your worst enemy.

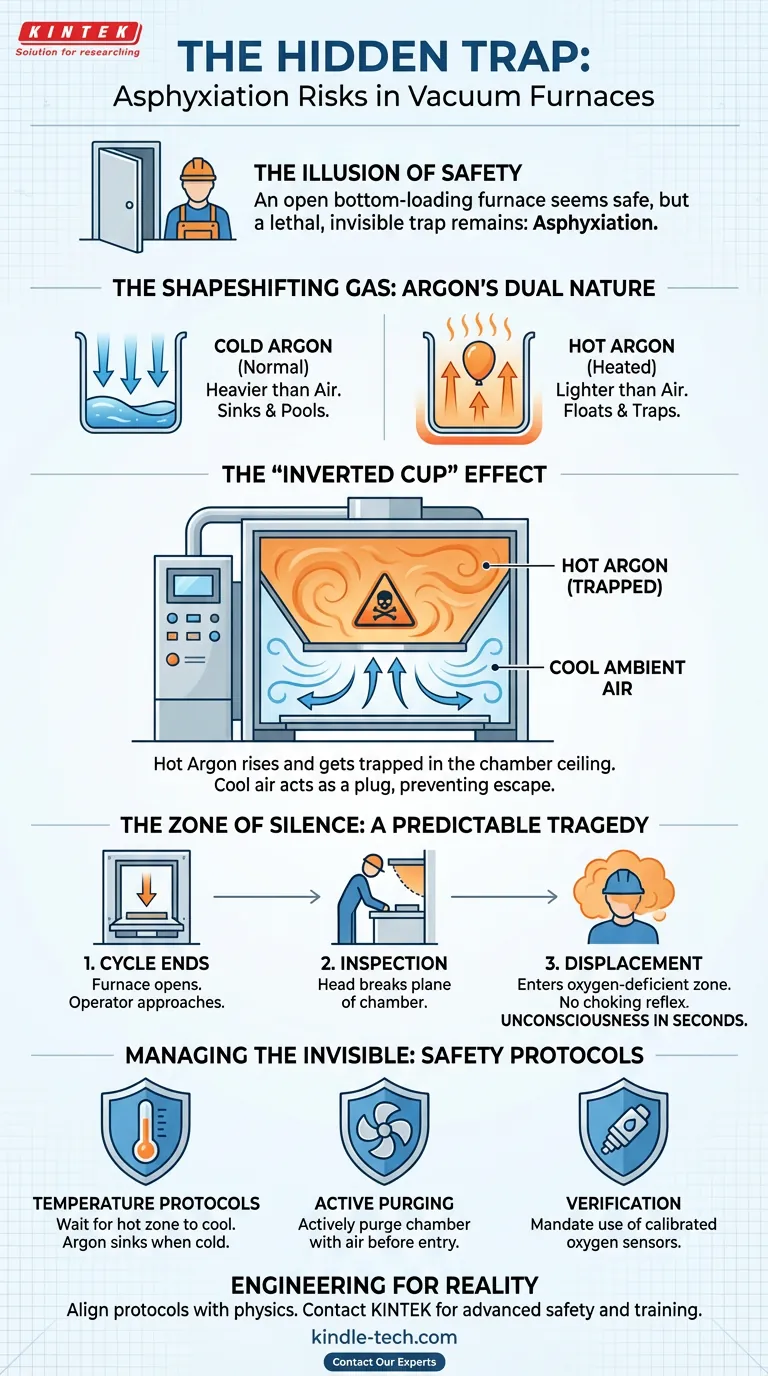

We are wired to believe that an open door equals safety. When the hearth of a bottom-loading vacuum furnace lowers and the chamber opens to the room, every instinct says the danger has passed. The cycle is over. The machinery is static. The path is clear.

Yet, this moment represents a specific, lethal blind spot in laboratory safety: Asphyxiation.

It happens not because the machine failed, but because the physics worked perfectly. The danger is invisible, odorless, and silent. It stems from a single, counter-intuitive interaction between heat and gas density.

The Shapeshifting Gas

To understand the trap, you have to understand the medium.

Argon is the standard choice for inert gas processing. Under normal conditions—at room temperature—Argon is roughly 38% denser than air. If you spilled a bucket of cold Argon, it would flow like water, pooling on the floor and draining out of low points.

Operators rely on this mental model: Argon sinks.

But heat changes the rules.

The Thermal Inversion

When gases heat up, their molecules vibrate violently and spread apart. This expansion drastically reduces density.

- Cold Argon: Sinks like a stone.

- Hot Argon: Floats like a balloon.

This is where the design of the furnace turns against the operator.

The "Inverted Cup" Effect

Consider the geometry of a bottom-loading vacuum furnace. It is essentially a bell jar or an inverted cup.

When the cycle ends, the bottom opens. If the Argon inside is still hot, it becomes significantly lighter than the cool, ambient air trying to enter from below.

Instead of flowing out, the hot Argon rises and becomes trapped in the "ceiling" of the furnace chamber.

The cool air from the room acts as a plug, holding the buoyant, deadly gas in place inside the chamber. The furnace has become a hot air balloon that cannot fly away.

The Zone of Silence

The tragedy usually unfolds in a predictable sequence:

- The Cycle Ends: The bottom lowers. The operator approaches.

- The Inspection: The operator leans up and into the chamber to inspect the hot zone or heating elements.

- The Displacement: The operator’s head breaks the plane of the chamber, entering the pocket of trapped hot Argon.

This environment is oxygen-deficient.

Because Argon is inert, it does not trigger the body’s "choking" reflex, which is caused by carbon dioxide buildup, not oxygen lack. There is no gasping. No burning eyes. No warning.

Unconsciousness strikes in seconds.

Managing the Invisible

Safety in a laboratory setting isn't about buying the most expensive helmet. It is about aligning your protocols with the immutable laws of physics.

You cannot negotiate with gas density, but you can manage it.

The Three Rules of Entry

- Temperature Protocols: Never break the plane of the furnace opening until the hot zone has cooled. Cooling restores Argon’s density, allowing it to sink and dissipate naturally.

- Active Purging: Do not rely on passive ventilation. If speed is required, the chamber must be actively purged with air.

- Verification: Intuition is not a measurement tool. Mandate the use of calibrated oxygen sensors before any physical entry.

Summary of the Hazard

| Variable | The Expectation | The Physical Reality |

|---|---|---|

| Gas Behavior | Argon is heavy and will fall out. | Hot Argon is light and floats. |

| Furnace Geometry | An open bottom allows drainage. | The chamber acts as a trap (Inverted Cup). |

| Physiology | I will feel like I'm choking. | You will blackout without warning. |

Engineering for Reality

The most dangerous risks are the ones that look like safety.

At KINTEK, we believe that high-performance equipment must be paired with high-level understanding. We design our vacuum furnaces and thermal solutions with the operator's reality in mind, but hardware is only half the equation. The other half is knowledge.

Don't let a "silent" hazard compromise your laboratory. Ensure your team understands the physics behind the equipment they use every day.

Is your safety protocol built on intuition or physics? Contact Our Experts to discuss advanced safety features, training, and equipment designed to protect your most valuable asset—your people.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

Related Articles

- Vacuum Induction Furnace Fault Inspection: Essential Procedures and Solutions

- The Art of the Void: When Precision Matters More Than Power

- Mastering Vacuum Furnace Brazing: Techniques, Applications, and Advantages

- Materials Science with the Lab Vacuum Furnace

- Why Your Brazed Joints Fail: The Truth About Furnace Temperature and How to Master It