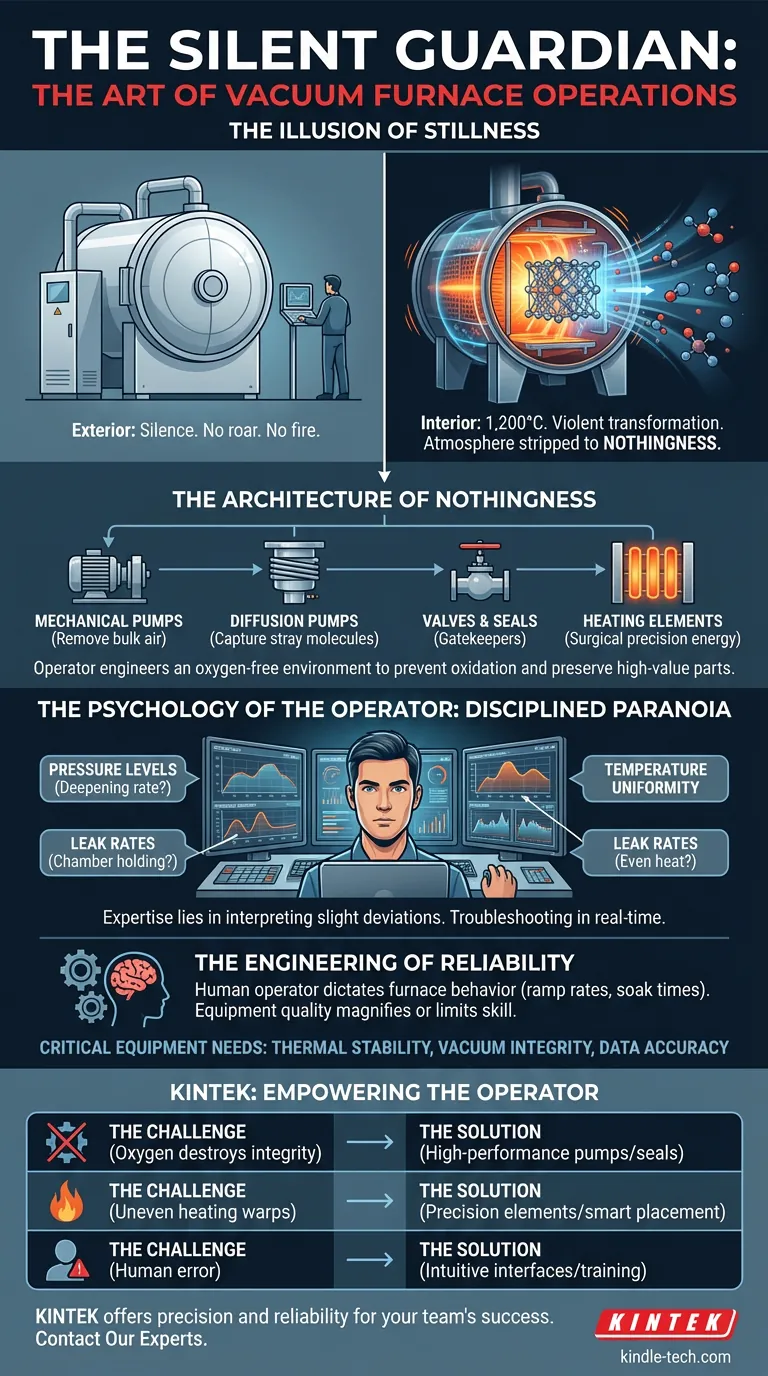

The Illusion of Stillness

Stand next to a vacuum furnace during a cycle, and you might be struck by the silence.

There is no roar of combustion. There is no visible fire. To the untrained eye, it looks like a large, static metal box.

But inside, a violent and precise transformation is occurring. Temperatures are climbing to 1,200°C. Metal lattices are vibrating, shifting, and reorganizing. And most importantly, the atmosphere is being stripped away, molecule by molecule, until the environment is emptier than space.

The person standing next to that box—the vacuum furnace operator—is not merely watching a machine. They are piloting a vessel through a hostile environment. They are the guardians of purity in a world desperate to oxidize.

The Architecture of Nothingness

We often think of heat treatment as a brute-force process: make it hot, make it hard.

But in advanced manufacturing—aerospace, medical devices, semiconductors—brute force ruins the product. The enemy is oxygen. At high temperatures, oxygen is a relentless contaminant. It scales surfaces, weakens alloys, and destroys the integrity of high-value parts.

The operator’s job is to engineer "nothingness."

This is not passive work. A vacuum furnace is a complex ecosystem of interdependent systems:

- Mechanical Pumps: The heavy lifters that remove the bulk of the air.

- Diffusion Pumps: The precision instruments that capture stray molecules.

- Valves and Seals: The gatekeepers of the vacuum integrity.

- Heating Elements: The source of energy that must be controlled with surgical precision.

When an operator initiates a cycle, they are conducting a symphony. If the vacuum pumps pull too hard before the furnace is ready, moisture freezes. If the heat ramps up before the oxygen is gone, the parts turn blue and brittle.

The Psychology of the Operator

Morgan Housel often writes that financial success is not about math; it is about behavior. The same is true for high-stakes metallurgy.

Being a vacuum furnace operator requires a specific psychological profile: disciplined paranoia.

A single load in a vacuum furnace can contain hundreds of thousands of dollars in machined parts. These components may have already spent weeks in production—milled, turned, and polished. The heat treatment is the final step.

If the operator fails, the parts are scrap. There is no "undo" button in metallurgy.

The Vigilance of Monitoring

The operator’s screen is a stream of data points:

- Pressure Levels: Is the vacuum deepening at the correct rate?

- Temperature Uniformity: Is the heat spreading evenly, or are there cold spots?

- Leak Rates: Is the chamber holding the vacuum, or is the atmosphere trying to break back in?

The difference between a novice and an expert is how they interpret a slight deviation. A novice sees a glitch. An expert sees a symptom—a failing O-ring, a struggling pump, or a sensor drift. They troubleshoot in real-time, often saving the batch before the alarm even sounds.

The Engineering of Reliability

There is a romantic notion in engineering that design solves everything. We believe that if we build the machine perfectly, the human element disappears.

Atul Gawande argues the opposite: the more complex the system, the more critical the human operator becomes.

The vacuum furnace is a perfect example. Theoretical physics dictates how the alloy should behave. But the operator dictates how the furnace behaves. They determine the ramp rates. They set the soak times. They load the basket to ensure radiative heat transfer isn't blocked by a shadow.

The Role of Equipment

However, even the most skilled pilot cannot fly a broken plane.

The operator’s skill is magnified or limited by the quality of the laboratory equipment they use. This is where the intersection of human talent and mechanical reliability becomes critical.

To maintain a contamination-free environment, the equipment must provide:

- Thermal Stability: No fluctuations during the critical soak phase.

- Vacuum Integrity: Seals and pumps that perform consistently over thousands of cycles.

- Data Accuracy: Sensors that tell the truth, every time.

KINTEK: Empowering the Operator

At KINTEK, we understand the pressure resting on the shoulders of the lab technician and the furnace operator. We know that when you are processing a critical sample, you are fighting against the natural chaos of thermodynamics.

We don't just sell equipment; we sell assurance.

Our vacuum furnaces and lab consumables are engineered to be the silent partner in your process. We focus on robust thermal insulation, precise control systems, and durable vacuum components so that your operators can focus on the metallurgy, not on fighting the machine.

Key Factors for Success

| Factor | The Challenge | The Solution |

|---|---|---|

| Atmosphere | Oxygen destroys surface integrity. | High-performance vacuum pumps and seals. |

| Temperature | Uneven heating warps parts. | Precision heating elements and smart placement. |

| Control | Human error during programming. | Intuitive interfaces and rigorous training. |

The Final Product

When the cycle finishes and the furnace cools, the operator opens the door.

If they have done their job well, and if their equipment has performed, the parts emerge bright and shiny. They have been heated to near their melting point, yet they look pristine. Their internal structure has changed—they are stronger, tougher, ready for the real world.

It is a quiet victory. But in the world of materials science, the quietest victories are the most important.

Do you need equipment that matches the skill of your team?

Your operators deserve tools that work as hard as they do. Whether you are setting up a new lab or upgrading your thermal processing capabilities, KINTEK offers the precision and reliability required for success.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

Related Articles

- The Architecture of Emptiness: Achieving Metallurgical Perfection in a Vacuum

- Why Your Heat-Treated Parts Fail: The Invisible Enemy in Your Furnace

- The Hidden Variable: Why Your Vacuum Furnace Results Are Inconsistent, and How to Fix Them for Good

- More Than Nothing: The Art of Partial Pressure in High-Temperature Furnaces

- The Engineering of Nothingness: Why Perfection Requires a Vacuum