Your high-temperature process has been running for 48 hours. You approach the furnace, anticipating perfect results, only to find the temperature has dropped and the cycle is ruined. The cause? A cracked or peeling heating element. This isn't just a minor equipment failure; it's a catastrophic loss of time, valuable materials, and irreplaceable data. For any lab or production facility relying on thermal processing, this scenario is a recurring nightmare that silently kills productivity and inflates operational costs.

The Hidden Enemy in Your High-Temperature Furnace

To defeat an enemy, you must first understand it. The workhorses of many high-temperature furnaces are Molybdenum Disilicide (MoSi2) heating elements, prized for their ability to operate reliably in air at extreme temperatures. Their secret is a remarkable self-healing mechanism: when heated, a thin, protective layer of quartz glass (SiO₂) forms on the surface, shielding the core from further oxidation.

However, this shield is not invincible. Several well-defined factors—the "dragons" of thermal processing—can lead to premature and unpredictable failure.

The "Pest" Oxidation Zone

The most notorious threat is a phenomenon known as "pesting." In the relatively low temperature range of 400°C to 700°C, MoSi2 elements undergo a catastrophic low-temperature oxidation. Instead of forming a protective layer, the element rapidly disintegrates into a powder. Spending too long in this temperature zone during heat-up or cool-down cycles is a death sentence for the component.

Death by Atmosphere and Stress

Even outside the pesting zone, danger lurks. The integrity of the protective SiO₂ layer is paramount, and it is vulnerable to attack:

- Chemical Attack: Reducing atmospheres, as well as vapors from acids, alkalis, and halogens, can aggressively strip away the protective layer, exposing the element's core to rapid degradation.

- Mechanical Stress: Improper installation is a common but overlooked cause of failure. Loose terminal clamps can cause arcing that destroys the element's cold end. Incorrect spacing from the furnace wall can create thermal stress points, leading to fractures.

- Thermal Shock: Using elements intermittently seems economical, but each heating cycle creates and stresses a new protective film. This repeated stress can cause the surface to peel, drastically shortening the element's lifespan compared to continuous operation.

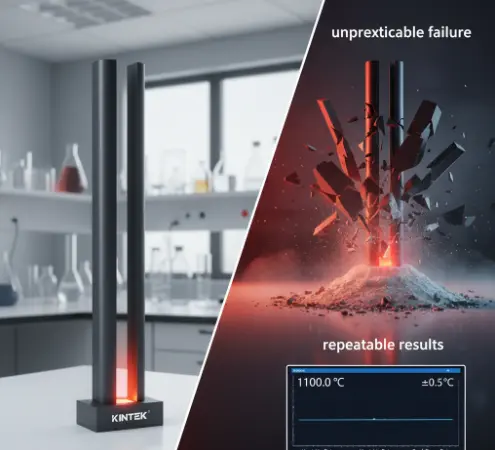

From Unpredictable Failures to Repeatable Results

The "heroic" moment in this story isn't a single discovery, but a fundamental shift in approach: treating heating elements not as disposable consumables, but as critical components of a precision system. Laboratories and production facilities that achieve exceptional reliability do so by implementing a rigorous operational protocol.

They meticulously plan their heating and cooling profiles to move through the 400-700°C "pest" zone as quickly as possible. Before its first use, every new furnace or set of elements undergoes a controlled "burn-in" at high temperature to form a mature, robust SiO₂ protective layer. They maintain strict control over furnace atmospheres and adhere to precise installation guidelines, ensuring every clamp is perfectly torqued and every element is correctly positioned.

The result of this diligence is transformative. Unscheduled downtime plummets. Experimental outcomes and production batches become highly consistent and repeatable. The focus shifts from reacting to failures to predicting and controlling performance.

The Critical Tool That Made This Reliability Possible

Achieving this level of process control isn't just about following a checklist; it begins with the intrinsic quality of the heating element itself. This is where the breakthrough becomes possible, thanks to the right tools.

The chronic issues of peeling, pesting, and premature fracture are often exacerbated by low-purity materials and inconsistent manufacturing in inferior heating elements. This is the challenge that KINTEK directly addresses.

Our MoSi2 heating elements are manufactured using exceptionally high-purity raw materials. This minimizes the microscopic impurity sites that can initiate cracks or disrupt the uniform formation of the vital SiO₂ protective layer. Paired with our precisely engineered clamps and mounting hardware, they eliminate the installation guesswork that leads to arcing and mechanical stress. We provide not just a component, but a foundational element of a reliable system, engineered to resist the very "dragons" that plague high-temperature work.

Beyond Reliability: Turning Thermal Processing into a Competitive Advantage

When your high-temperature processes become predictable, the entire scope of your work changes. You are no longer held hostage by the unpredictable lifespan of a critical component. Instead of budgeting for constant replacements and production losses, you can focus on innovation.

For materials scientists, this means faster discovery cycles. For semiconductor manufacturing, it means higher yields and less wafer scrappage. For quality control labs, it means unwavering confidence in test results. By eliminating a primary source of operational risk, you turn your thermal processing capability from a potential liability into a distinct competitive advantage. The true victory isn't just a longer-lasting heating element; it's the new research and production possibilities that unwavering reliability unlocks.

The principles that ensure the longevity of a single heating element are the same principles that build a more efficient and productive operation. If you're ready to move beyond fighting daily fires and start building a truly reliable thermal processing system, our team is here to help you analyze your specific application and challenges.

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Multi-zone Laboratory Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

Related Articles

- Understanding Electric Heating Systems(2): From Furnaces to Heating Elements

- Optimizing Performance with Graphite Vacuum Furnaces: A Comprehensive Guide

- Why Your High-Temperature Furnace Elements Fail: The Critical Difference in Silicon Carbide

- Dos and don'ts during the installation of molybdenum disilicide (MoSi2) heating element

- Investigating the Factors Affecting the Slow Temperature Rise in Box Furnaces