The 1800°C Failure: When Hitting the Target Isn't Enough

Imagine this: weeks of work, expensive raw materials, and a critical project deadline all hinge on your next vacuum furnace run. You've programmed the cycle for a new advanced material, aiming for a peak temperature of 1800°C—well within your furnace's specified capabilities. You wait, hopeful.

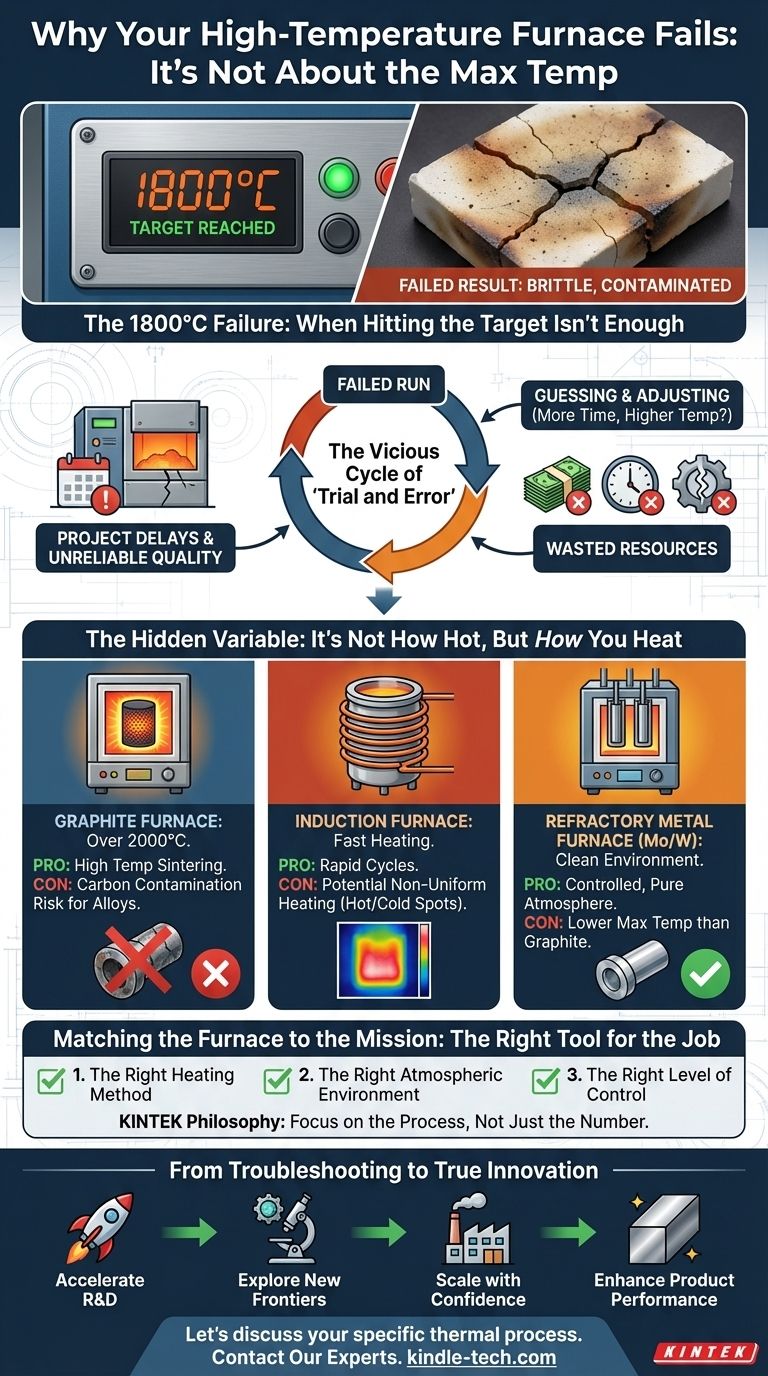

But when you open the chamber, the result is a disaster. The material is brittle, contaminated, or simply didn't sinter correctly. The furnace display confirmed it hit 1800°C. So what went wrong? You've just encountered one of the most frustrating and misunderstood problems in materials science: hitting the target temperature is not the same as achieving the desired outcome.

The Vicious Cycle of 'Trial and Error'

If this scenario feels familiar, you are not alone. Across countless R&D labs and production facilities, teams are stuck in a costly loop of troubleshooting their thermal processes. The common response to a failed run is to start guessing:

- "Let's run it again, maybe it was a fluke."

- "Maybe the raw material powder was contaminated."

- "Let's try increasing the 'soak' time by an hour."

- "Maybe we should push the temperature to 1850°C?"

Each of these attempts is a shot in the dark. This isn't just a scientific frustration; it's a significant business problem. Every failed cycle translates directly into:

- Wasted Budgets: Expensive raw materials are consumed, energy costs mount, and valuable man-hours are spent on repeating work instead of advancing projects.

- Project Delays: Critical R&D milestones are missed, and production schedules slip, delaying time-to-market for new products.

- Unreliable Quality: Inconsistent material properties can lead to component failure, damaging your company's reputation and credibility.

These repeated failures happen because the troubleshooting efforts are focused on the symptoms, not the underlying disease.

The Hidden Variable: It's Not How Hot, But How You Heat

The core reason for these failures lies in a common misconception: that the most important specification for a vacuum furnace is its maximum temperature. This is like judging a chef's ability based only on how hot their oven can get.

The truth is, a material's final properties are determined by a delicate interplay of factors, with peak temperature being just one. The real root cause of failure is often a fundamental mismatch between the furnace's heating technology and the material's specific processing needs.

Here’s what that means in practice:

Not All Heat is Created Equal

The way a furnace generates and contains heat is critical. The materials used in its construction define its capabilities and limitations.

- A graphite furnace can reach extremely high temperatures (over 2000°C), making it ideal for sintering certain ceramics. However, at these temperatures, it can introduce carbon into the atmosphere, which can contaminate sensitive metal alloys, ruining them.

- An induction furnace heats incredibly fast by inducing an electric current directly within the metal. But this method can sometimes lead to non-uniform heating, creating hot and cold spots in complex parts.

- A standard refractory metal furnace (using Molybdenum or Tungsten elements) provides a very clean, controlled environment but typically operates at a lower maximum temperature than a graphite furnace.

Chasing the highest temperature spec without understanding these trade-offs is why a furnace rated for 2200°C might fail at a process where a 1300°C furnace would succeed. You were treating the symptom (temperature) while ignoring the cause (furnace environment and heating method).

Matching the Furnace to the Mission: The Right Tool for the Job

To permanently escape the cycle of trial and error, you don't need a furnace that just gets "hotter." You need a furnace system that provides:

- The right heating method for your specific material.

- The right atmospheric environment to prevent contamination.

- The right level of control over the entire thermal cycle—from ramp-up to soak and cool-down.

This is precisely the philosophy behind KINTEK's approach to laboratory equipment. We understand that a vacuum furnace is not a commodity oven; it is a precision instrument. It is a tool designed to solve a specific scientific or engineering challenge.

Our range of vacuum furnaces is not built to win a "max temp" competition. It is engineered to provide the correct solution for distinct applications:

- Our standard vacuum furnaces are perfect for clean, precise processes like brazing and annealing steels up to 1300°C, where control and consistency are paramount.

- Our specialized vacuum graphite and induction furnaces are designed for those pushing the boundaries with advanced ceramics or refractory metals, where achieving temperatures of 2000°C and beyond is necessary, and the system is built to manage the unique challenges at those extremes.

By focusing on the process first, we ensure the furnace you choose is not just capable of reaching a number, but is fundamentally designed to produce the material transformation you require.

From Troubleshooting to True Innovation

When you stop fighting your tools and start using the right one, the focus shifts. The time, budget, and mental energy previously wasted on troubleshooting are now freed up for what truly matters: innovation.

With a furnace correctly matched to your process, you can:

- Accelerate R&D: Move from concept to validated material faster than ever before, knowing your results are repeatable and reliable.

- Explore New Frontiers: Confidently experiment with novel alloys, advanced composites, and next-generation ceramics that were previously too risky or difficult to process.

- Scale with Confidence: Seamlessly transition a successful laboratory process to pilot production with predictable, high-quality outcomes.

- Enhance Product Performance: Create materials with superior strength, purity, and specific properties that give your final product a competitive edge in the market.

Ultimately, solving the furnace problem isn't just about getting better data; it's about unlocking your lab's full potential to invent, improve, and lead.

Your materials have unique requirements, and your projects have ambitious goals. Stop letting a mismatched furnace dictate your limits. Let's discuss the specific thermal process you need to master and equip your lab for success. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

Related Articles

- The Engineering of Nothingness: Why Vacuum Furnaces Define Material Integrity

- Why Your High-Performance Parts Fail in the Furnace—And How to Fix It for Good

- Why Your Brazed Joints Are Inconsistent—And the Fix Isn't in the Furnace

- Vacuum Induction Furnace Fault Inspection: Essential Procedures and Solutions

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.