Yes, polymers can absolutely be deposited using Chemical Vapor Deposition (CVD). While CVD is more famously associated with hard materials like silicon carbide or metals, the process has been reliably adapted to create high-purity, ultra-thin polymer films for specialized, high-performance applications.

While most think of CVD for creating robust ceramic or metallic layers, its application to polymers represents a sophisticated technique for engineering surfaces where conventional liquid-phase methods fall short. It allows for the direct synthesis of polymer films from gaseous precursors, offering unparalleled control and purity.

The Role of CVD in Polymer Deposition

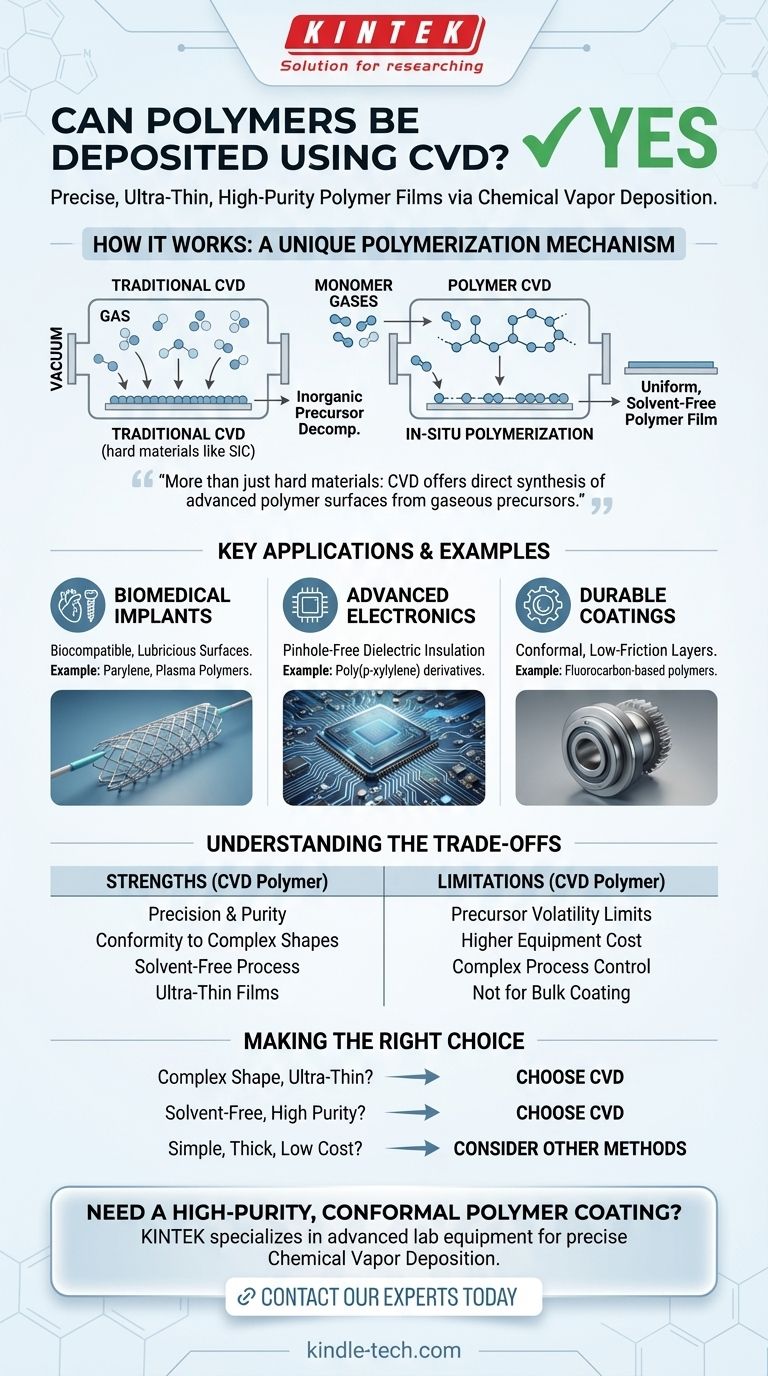

While the core principles of CVD remain, the application to polymers involves a unique approach compared to depositing traditional inorganic materials.

A Departure from Conventional Materials

CVD is a cornerstone technology for depositing a wide range of inorganic compounds. Its ability to create dense, high-purity coatings is well-established for materials like silicon carbide, pyrolytic carbon, boron nitride, and various metallic compounds.

The adaptation of this process for organic polymers leverages the same fundamental advantage: building a material layer-by-layer from a chemical reaction in the vapor phase.

The Polymerization Mechanism

Instead of decomposing a gas to deposit an element like silicon, polymer CVD introduces monomer gases into a vacuum chamber. These monomers adsorb onto a substrate surface and are then triggered to link together, or polymerize, directly on that surface.

This in-situ polymerization builds the polymer film one chain at a time, resulting in a coating that is exceptionally uniform and free from the solvents or impurities common in traditional polymer processing.

Proven Applications and Key Examples

The value of polymer CVD is most evident in fields where surface properties are critical and coating integrity is paramount.

Biomedical Device Implants

CVD polymer coatings are used to create biocompatible or lubricious surfaces on medical implants. These ultra-thin films can improve how a device interacts with the body, reducing friction or preventing adverse reactions, without changing the bulk properties of the implant.

Advanced Electronics

In electronics, thin polymer films serve as excellent dielectric insulators or protective barriers. CVD is used to apply these coatings onto complex topographies like circuit boards, ensuring complete, pinhole-free coverage that protects sensitive components from moisture and electrical interference.

Durable and Lubricious Coatings

Beyond specific industries, CVD polymers are used to create highly durable, low-friction surfaces for a variety of mechanical applications. These coatings can significantly reduce wear and tear on moving parts where traditional liquid lubricants are not practical.

Understanding the Trade-offs

Polymer CVD is a powerful but specialized tool. It is not a universal replacement for all polymer coating methods.

Material and Precursor Limitations

The primary limitation is the need for suitable starting materials. The process requires monomers that can be vaporized without decomposing. This restricts the range of polymers that can be deposited compared to the vast library of polymers available through conventional synthesis.

Process Complexity and Cost

CVD is inherently a vacuum-based technology, which involves higher equipment costs and more complex process control compared to simpler methods like dip-coating or spray-coating. It is best reserved for applications where its unique benefits justify the investment.

Making the Right Choice for Your Application

Choosing a deposition method depends entirely on your end goal. Polymer CVD excels where precision, purity, and conformity are non-negotiable.

- If your primary focus is an ultra-thin, conformal coating on a complex shape: CVD is an excellent choice for applications like medical stents or microelectronics.

- If your primary focus is creating a completely solvent-free, high-purity polymer film: CVD provides a distinct advantage over wet-chemistry methods that can leave residual impurities.

- If your primary focus is applying a simple, thick protective coating to a flat surface: Simpler and less expensive methods like spin-coating or spray-coating are likely more appropriate.

Ultimately, polymer CVD provides a powerful solution for creating advanced functional surfaces that are impossible to achieve with conventional techniques.

Summary Table:

| Application | CVD Polymer Benefit | Example Polymers/Materials |

|---|---|---|

| Biomedical Implants | Biocompatible, lubricious surfaces | Parylene, Plasma Polymers |

| Advanced Electronics | Pinhole-free dielectric insulation | Poly(p-xylylene) derivatives |

| Durable Coatings | Conformal, low-friction layers | Fluorocarbon-based polymers |

Need a high-purity, conformal polymer coating for your specialized application? KINTEK specializes in advanced lab equipment and consumables for precise Chemical Vapor Deposition processes. Whether you are developing medical implants, advanced electronics, or durable coatings, our expertise ensures you achieve the ultra-thin, solvent-free films your project demands. Contact our experts today to discuss how our solutions can enhance your R&D and production capabilities.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings