Yes, absolutely. Melting copper in a graphite crucible is not only possible but is the standard and recommended practice for most small-scale and industrial applications. Graphite's exceptional thermal properties and chemical stability make it an ideal container for handling molten copper.

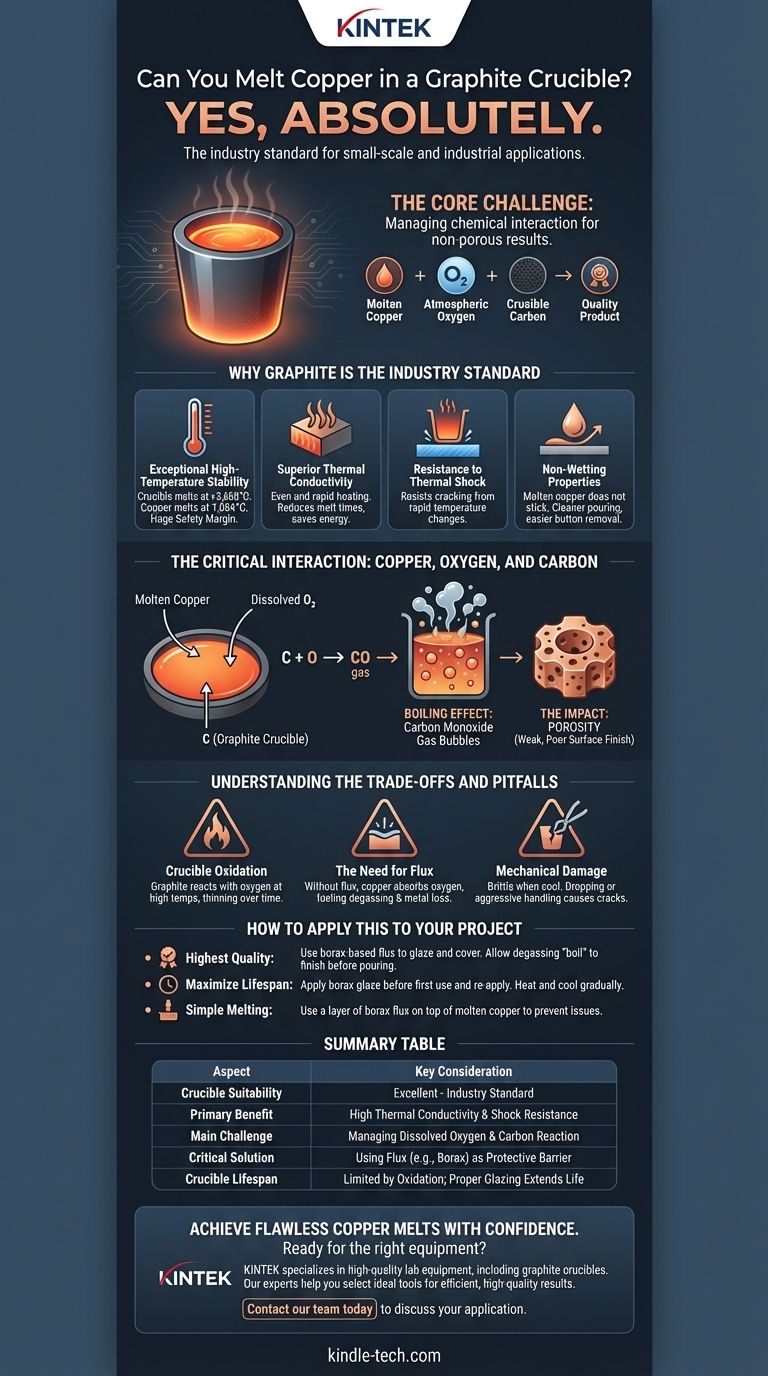

The core challenge isn't whether graphite can handle the heat, but how to manage the chemical interaction between molten copper, atmospheric oxygen, and the carbon of the crucible to ensure a high-quality, non-porous final product.

Why Graphite is the Industry Standard

Graphite possesses a unique combination of properties that make it superior for high-temperature metallurgical work, especially with non-ferrous metals like copper.

Exceptional High-Temperature Stability

A graphite crucible's melting point is extremely high, over 3,600°C (6,500°F). This is far above the melting point of copper, which is 1,084°C (1,984°F), providing an enormous margin of safety.

Superior Thermal Conductivity

Graphite conducts heat very efficiently. This allows for even and rapid heating of the copper, reducing melt times and saving energy.

Resistance to Thermal Shock

The material is highly resistant to cracking from rapid temperature changes. You can take a hot graphite crucible and place it on a cooler (but still refractory) surface without it shattering, a critical property for casting operations.

Non-Wetting Properties

Molten copper does not easily "wet" or stick to the surface of a properly prepared graphite crucible. This makes pouring cleaner and simplifies the removal of the solidified metal "button" left over after a pour.

The Critical Interaction: Copper, Oxygen, and Carbon

While graphite is the right material, understanding its interaction with molten copper and air is crucial for success. The primary issue you may encounter is a "boiling" or bubbling effect in your melt.

Copper's Affinity for Oxygen

When copper becomes molten, it acts like a sponge for oxygen, readily dissolving it from the surrounding atmosphere. This dissolved oxygen is the root cause of most problems.

The Degassing Reaction

The dissolved oxygen in the molten copper can react directly with the carbon of the crucible.

This reaction (C + O → CO gas) produces carbon monoxide gas bubbles within the melt. This is what creates the "boiling" effect. It is not the copper itself boiling, but a chemical reaction releasing gas.

The Impact: Porosity

If this gas is still being produced as you pour the metal into a mold, the bubbles will become trapped as the copper solidifies. This results in porosity—a final casting riddled with tiny holes, which severely weakens the part and ruins its surface finish.

Understanding the Trade-offs and Pitfalls

Using graphite crucibles requires some care to maximize their lifespan and ensure melt quality.

Crucible Oxidation

At high temperatures, the graphite itself will react with oxygen in the air and slowly burn away, becoming thinner over time. This is the primary factor limiting a crucible's lifespan.

The Need for Flux

Without a protective layer, your molten copper will continuously absorb oxygen from the air, fueling the degassing reaction. This leads to metal loss (as it gets trapped in slag) and the persistent risk of porosity.

Mechanical Damage

Graphite is strong at high temperatures but can be brittle when cool. Dropping the crucible or being too aggressive with tongs and stirring rods can easily cause chips and cracks, rendering it unsafe for use.

How to Apply This to Your Project

Proper technique transforms a good material into a great result. Following these steps will protect your crucible and improve the quality of your copper melts.

- If your primary focus is achieving the highest quality, non-porous castings: Use a borax-based flux to both glaze the crucible and cover the melt, and allow the degassing "boil" to finish completely before pouring.

- If your primary focus is maximizing crucible lifespan: Always apply a borax glaze before the first use and re-apply as needed to seal the graphite from atmospheric oxygen, and heat and cool the crucible gradually.

- If your primary focus is simple, hobby-level melting: Even for basic projects, using a layer of borax flux on top of the molten copper is the single most important step you can take to prevent issues.

By managing the chemistry of the melt, you can consistently achieve clean, high-quality results with your copper casting.

Summary Table:

| Aspect | Key Consideration |

|---|---|

| Crucible Suitability | Excellent - Industry standard for copper melting. |

| Primary Benefit | High thermal conductivity and resistance to thermal shock. |

| Main Challenge | Managing the reaction between dissolved oxygen in copper and carbon from the crucible. |

| Critical Solution | Using a flux (e.g., borax) to create a protective barrier and prevent gas porosity. |

| Crucible Lifespan | Primarily limited by oxidation; proper glazing and handling extend life. |

Achieve Flawless Copper Melts with Confidence

Ready to get the right equipment for your project? The key to success lies in using the proper crucible and techniques.

KINTEK specializes in high-quality lab equipment and consumables, including the right graphite crucibles for your specific copper melting needs. Our experts can help you select the ideal tools to ensure efficient, high-quality results while maximizing the lifespan of your equipment.

Contact our team today to discuss your application and let us provide the reliable solutions your laboratory deserves.

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- Carbon Graphite Boat -Laboratory Tube Furnace with Cover

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

People Also Ask

- How are crucibles made? The Secret to Superior Performance and Safety

- What is the best crucible for melting gold? Choose the Right Crucible for Safety & Purity

- What are the functions of a high-purity graphite crucible in the FFC Cambridge process? Optimize Your Alloy Production

- What is the efficiency of a crucible furnace? A Guide to Thermal Performance & Trade-offs

- Why is a glass sintered crucible required for pulp separation? Achieve 100% Precision in Wood Fractionation

- Why are high-purity corundum crucibles preferred for Fe-13Cr alloys? Ensure Melt Purity and Stability

- What are the advantages of sintered glass crucible as used in filtration? Achieve Purity and Precision in Your Lab

- Can you melt gold in a crucible? Yes, with the right crucible, heat source, and safety process.