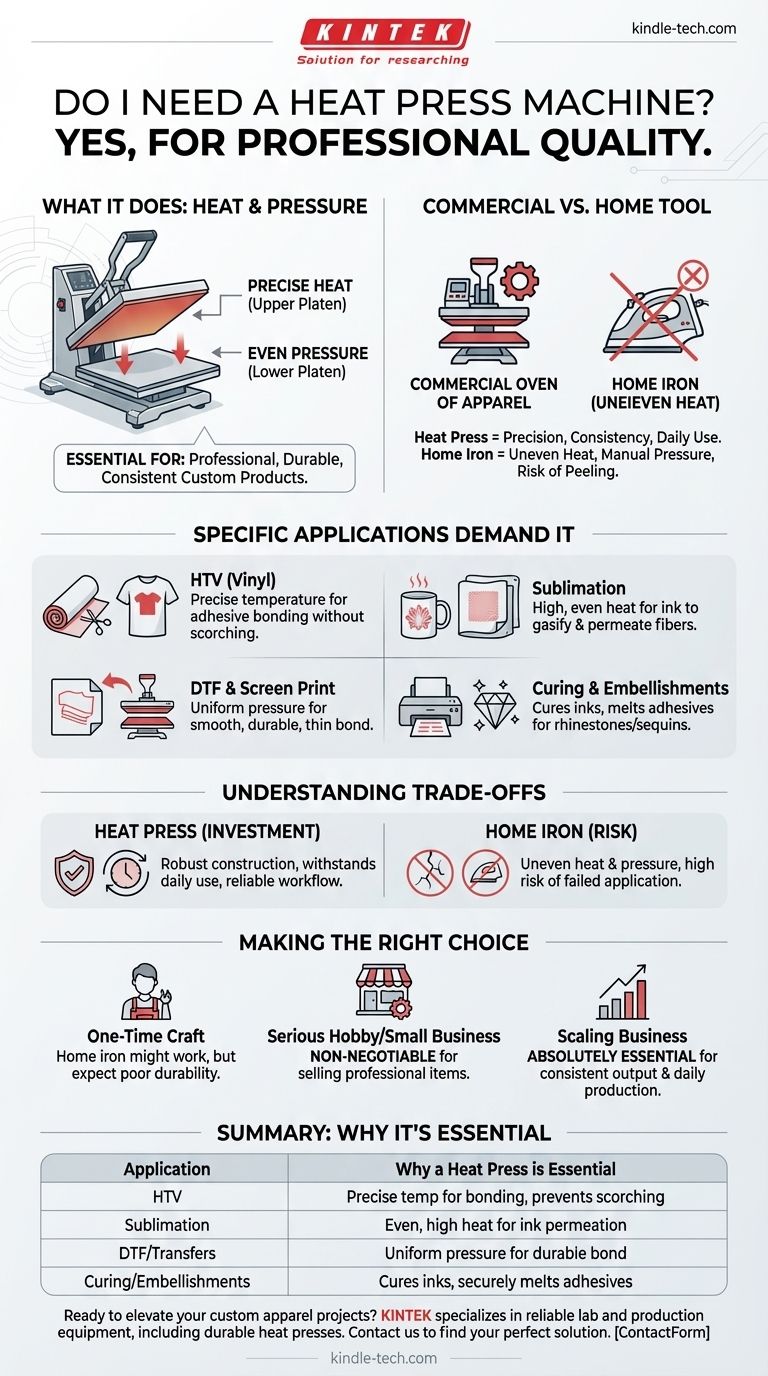

In short, yes, you need a heat press machine if you intend to create professional, durable, and consistent custom products. It is a specialized machine that applies designs using a precise combination of controlled heat and even pressure—two factors that are essential for a high-quality, lasting application that alternatives cannot reliably replicate.

A heat press is the bridge between a hobbyist craft and a professional-grade product. The decision to invest in one comes down to your commitment to quality, durability, and the specific decoration methods you plan to use, such as vinyl, sublimation, or film transfers.

What a Heat Press Actually Does

A common misconception is that a heat press is just a large, heavy iron. This isn't accurate. It's a purpose-built tool designed for one job: to bond one material to another perfectly, every single time.

The Core Principle: Heat and Pressure

A heat press operates with two surfaces, known as platens. The upper platen heats up to a precise temperature, while the lower platen provides a flat, stable surface for your item.

When the machine is engaged, it clamps the upper platen down with significant, evenly distributed pressure. This combination of exact temperature and consistent pressure is what activates adhesives and inks, forcing them to permanently bond with the substrate.

The Commercial vs. Home Tool Analogy

Think of the difference between a commercial kitchen oven and a home oven. Both can bake, but the commercial oven is built for precision, consistency, and the rigors of constant use.

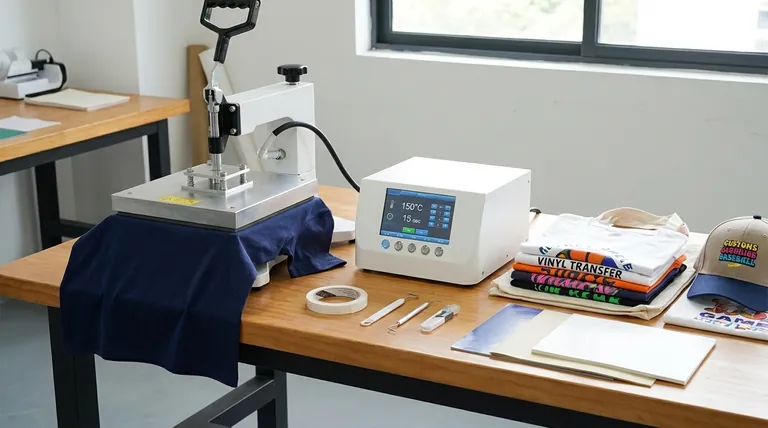

A heat press is the commercial oven of apparel decoration. It is constructed to be robust and to withstand the physical demands of daily operation, ensuring every t-shirt, bag, or jersey you produce meets the same quality standard.

Specific Applications That Demand a Heat Press

Different decoration methods have unique requirements for heat and pressure. Using a tool that doesn't meet these requirements often leads to peeling, cracking, or faded designs after just a few washes.

For Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl relies on a heat-activated adhesive. A heat press ensures the entire design reaches the exact temperature needed to bond properly without scorching the vinyl or the garment.

For Sublimation Transfers

Sublimation is a chemical process where solid ink turns directly into a gas. It requires high, even heat to permeate the polyester fibers of the substrate. Without the consistent temperature of a press, the transfer will be blotchy and incomplete.

For DTF and Screen Print Transfers

Direct-to-Film (DTF) and Screen Print Transfers use specialized adhesives that must be melted and pressed firmly into the fabric. The even pressure from a heat press is critical for achieving a smooth, durable bond that doesn't feel overly thick or plastic.

For Curing Inks and Embellishments

A heat press is also used to cure the inks from direct-to-garment printers, making them permanent and washable. Similarly, it melts the glue on hotfix rhinestones or sequins, pressing them firmly onto a garment for a secure application.

Understanding the Trade-offs

While a heat press is a superior tool, the decision to purchase one involves understanding what you are gaining and what you are giving up by choosing a lesser alternative.

The Downside of a Home Iron

A standard household iron is the most common alternative, but it is fundamentally unsuited for this work. Its heat is uneven, with hot and cool spots across its surface.

Furthermore, it's impossible to apply consistent pressure by hand. This combination of uneven heat and pressure is the primary cause of transfers that peel off or crack after washing.

The Investment in Durability

A quality heat press is an investment. Its robust construction is meant to handle the physical force of being opened and closed hundreds of times a day. This durability is what ensures your machine will remain a reliable part of your workflow for years.

Space and Power Considerations

These are not small, lightweight appliances. A heat press requires a dedicated, sturdy workspace and may draw a significant amount of power. Factoring in the physical footprint and electrical needs is a practical part of the decision.

Making the Right Choice for Your Goal

Your need for a heat press is directly tied to the quality of the outcome you want to achieve.

- If your primary focus is a one-time personal craft: You might attempt to use a home iron, but you must accept the high risk of a failed application and poor durability.

- If your primary focus is starting a serious hobby or small business: A heat press is a non-negotiable, foundational tool for producing professional-quality items that you can confidently sell.

- If your primary focus is scaling an existing decoration business: A high-quality, durable heat press is absolutely essential for maintaining consistent output and withstanding the demands of daily production.

Ultimately, investing in a heat press is the clearest step you can take to move from inconsistent results to reliable, professional production.

Summary Table:

| Application | Why a Heat Press is Essential |

|---|---|

| Heat Transfer Vinyl (HTV) | Ensures precise temperature for adhesive bonding, preventing peeling or scorching. |

| Sublimation | Provides even, high heat for ink to gasify and permeate polyester fibers completely. |

| DTF/Screen Print Transfers | Applies uniform pressure for a smooth, durable bond without a thick, plastic feel. |

| Curing & Embellishments | Cures DTG inks and securely melts adhesives for rhinestones or sequins. |

Ready to elevate your custom apparel projects with professional-grade results? KINTEK specializes in reliable lab and production equipment, including heat press machines designed for durability and precision. Whether you're a serious hobbyist or scaling a business, our solutions ensure consistent, high-quality outcomes. Contact us today to find the perfect heat press for your needs!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Automatic Laboratory Heat Press Machine

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Are heat press attachments interchangeable? Avoid Costly Mistakes with Brand-Specific Compatibility

- What are the advantages of using a hot press over a cold press for LiMOCl4 composite cathodes? Boost Battery Efficiency

- What are the steps in the hot pressing process? Achieve Maximum Density for Complex Parts

- Why is a hot press utilized for 70Li2S-30P2S5 glass-ceramic electrolytes? Maximize Ionic Conductivity & Densification

- Why are precision molds and pressure control essential for TlBr hot pressing? Enhance Semiconductor Performance

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- Why increase the temperature when forging? Achieve Superior Strength and Formability

- What role does a laboratory hot press play in shielding materials? Optimize Polyaniline/Wollastonite Composite Density