Yes, absolutely. Hydraulic pressure changes significantly with temperature, primarily because temperature alters the physical properties of the hydraulic fluid itself. In a sealed hydraulic system, even a modest temperature increase can cause a dramatic and potentially dangerous rise in pressure due to the thermal expansion of the trapped fluid.

The core issue isn't that pressure and temperature are inherently linked, but that temperature directly affects the volume and viscosity of hydraulic fluid. In a fixed-volume system, a change in fluid volume has nowhere to go, forcing a massive change in system pressure.

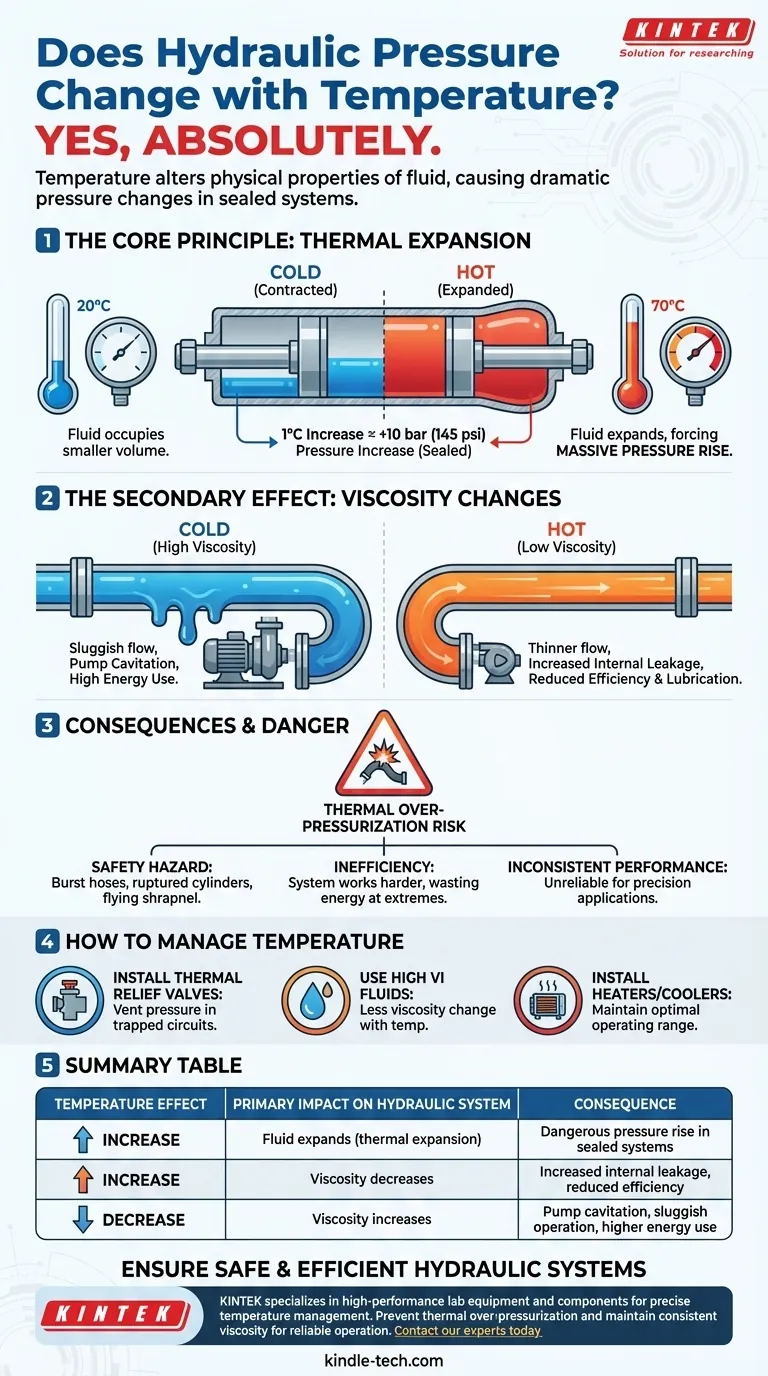

The Core Principle: Thermal Expansion

The most direct and powerful way temperature affects hydraulic pressure is through the principle of thermal expansion. This is a fundamental concept in physics that dictates how substances react to heat.

How Thermal Expansion Works

Nearly all materials, including liquids like hydraulic oil, expand when heated and contract when they cool. The molecules in the fluid gain kinetic energy as temperature rises, causing them to move more vigorously and occupy a larger volume.

This change is quantified by the fluid's coefficient of thermal expansion. For typical mineral-based hydraulic oils, this value is around 0.0007 per degree Celsius (0.0004 per degree Fahrenheit).

The Impact in a Sealed System

While a small expansion in an open container is unnoticeable, the effect is amplified dramatically in a sealed, fixed-volume hydraulic circuit, like a blocked cylinder or line.

Imagine a hydraulic cylinder completely filled with oil and sealed at both ends. As the ambient temperature rises—for example, from the sun beating down on the equipment—the oil tries to expand. Since the steel cylinder's volume is relatively fixed, the expanding fluid has nowhere to go.

This creates an immense increase in static pressure. The relationship is so direct that a temperature rise of just 1°C can increase the pressure by over 10 bar (145 psi). A 50°C (90°F) swing could theoretically generate over 500 bar (7,250 psi) of pressure, far exceeding the safe operating limits of many components.

The Secondary Effect: Viscosity Changes

Temperature also has a profound effect on the fluid's viscosity, which is its resistance to flow. This doesn't affect static pressure in a sealed line but has a huge impact on the system's dynamic performance.

Temperature's Influence on Viscosity

The relationship between temperature and viscosity is inverse.

- As temperature increases, viscosity decreases. The oil becomes thinner and flows more easily, like warming up honey.

- As temperature decreases, viscosity increases. The oil becomes thicker and more resistant to flow.

Practical Consequences of Viscosity Change

This change in flow characteristic directly impacts how the hydraulic system operates.

At high temperatures, low viscosity can lead to increased internal leakage past seals in pumps, motors, and valves. This reduces efficiency, causes components to respond more slowly, and diminishes the fluid's ability to create a strong lubricating film, accelerating wear.

At low temperatures, high viscosity makes the fluid sluggish. This can starve the pump (cavitation), significantly increase the energy required to operate the system, and make actuator movements slow and unresponsive.

Understanding the Trade-offs and Safety Implications

Ignoring the effects of temperature is not an option in hydraulic design or maintenance. The consequences range from inefficiency to catastrophic failure.

The Danger of Thermal Over-Pressurization

The single greatest risk is the pressure buildup in a sealed or blocked part of a circuit. A piece of equipment parked in the sun can easily experience a temperature swing sufficient to burst a hose or rupture a cylinder, creating a severe safety hazard from high-pressure fluid injection or flying shrapnel.

This is precisely why critical systems must be protected with thermal relief valves, which are designed to vent small amounts of fluid to relieve pressure caused by thermal expansion.

The Inefficiency of Operating at Wrong Temperatures

A system running too hot or too cold is an inefficient system. When cold, the prime mover (engine or motor) must work much harder just to pump the thick fluid, wasting fuel or electricity. When hot, internal leakage means the pump must work harder to achieve the same amount of work, again wasting energy.

The Challenge of Inconsistent Performance

For applications requiring precision, like CNC machinery or aircraft flight controls, temperature-induced changes can be a major problem. Changes in fluid viscosity can alter valve timing and actuator speed, leading to unpredictable and unreliable system behavior.

How to Manage Temperature in Your Hydraulic System

Effectively managing temperature is about ensuring safety, reliability, and efficiency. Your approach will depend on your system's design and operating environment.

- If your primary focus is safety: You must install thermal relief valves in any part of the circuit that can trap a fixed volume of fluid, such as between a cylinder and a closed directional control valve.

- If your primary focus is consistent performance: Select a high-quality, multi-grade hydraulic fluid with a high Viscosity Index (VI), which means its viscosity changes less with temperature. For extreme environments, consider installing system heaters for cold climates or coolers (heat exchangers) for hot climates.

- If your primary focus is troubleshooting pressure issues: Always measure both pressure and fluid temperature at the same time. A pressure reading that climbs steadily with temperature in a non-operating system is a clear sign of thermal expansion.

Controlling the effects of temperature is fundamental to designing and maintaining a safe, reliable, and efficient hydraulic system.

Summary Table:

| Temperature Effect | Primary Impact on Hydraulic System | Consequence |

|---|---|---|

| Increase | Fluid expands (thermal expansion) | Dangerous pressure rise in sealed systems |

| Increase | Viscosity decreases | Increased internal leakage, reduced efficiency |

| Decrease | Viscosity increases | Pump cavitation, sluggish operation, higher energy use |

Ensure your hydraulic systems operate safely and efficiently across all temperatures. KINTEK specializes in high-performance lab equipment and consumables, including hydraulic system components designed for precise temperature management. Our solutions help prevent thermal over-pressurization and maintain consistent viscosity for reliable operation. Contact our experts today to discuss how we can support your laboratory's hydraulic equipment needs with tailored solutions.

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press ensure the quality of oxide ceramic bulk materials? Achieve Precision Compaction

- What is the function of a laboratory hydraulic press and a 15 mm circular mold? Create Dense Oxygen Membrane Green Bodies

- Press forging vs. hammer forging: Which is right for your metal forming needs?

- What is the necessity of using a laboratory hydraulic press for RDF TGA? Optimize Your Thermal Analysis Accuracy

- How is a Laboratory Hydraulic Press used during the contact angle testing of limestone powders? | Sample Prep Guide

- How does a laboratory hydraulic press contribute to the preparation of fly ash composite samples? Precision Pressing

- What size is a forging press? Match Tonnage & Footprint to Your Forging Needs

- What role does a laboratory hydraulic press play in MFC air cathode assembly? Precision Compaction for Peak Performance