At its core, a resistive heating element works by converting electrical energy directly into heat. This is achieved by passing an electrical current through a material that is specifically designed to have high electrical resistance. This resistance acts like friction for the flowing electricity, causing the material to heat up, a phenomenon known as Joule heating.

The effectiveness of a resistive heating system isn't just about creating heat; it's about selecting a material that can generate intense heat efficiently and withstand extreme temperatures repeatedly without degrading or melting.

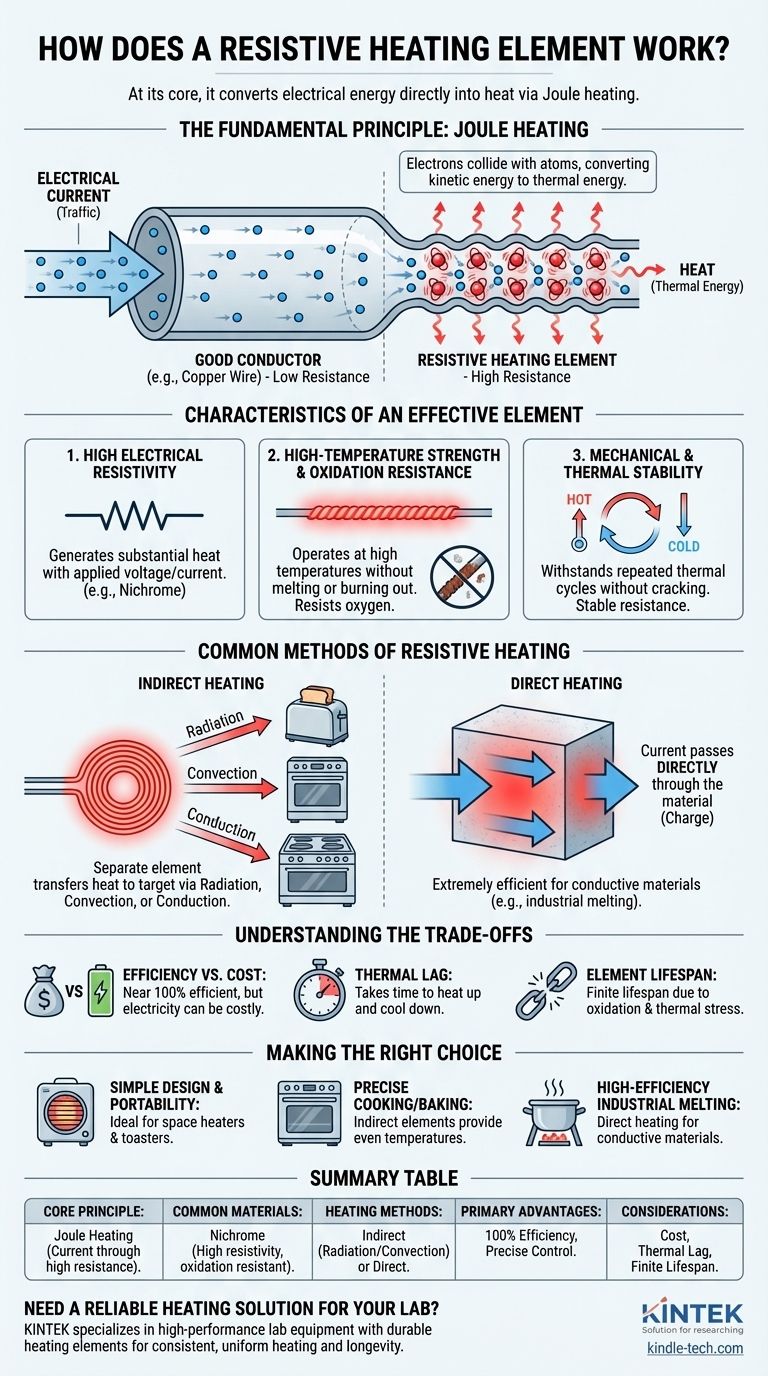

The Fundamental Principle: Joule Heating

The science behind every electric toaster, oven, and industrial furnace is a simple and elegant principle. Understanding it allows you to see why certain materials and designs are chosen over others.

What is Joule Heating?

Think of an electrical current as traffic flowing down a highway. In a good conductor like a copper wire, the road is wide and smooth, and electrons (the cars) flow with very little obstruction.

A resistive heating element, however, is like a narrow, bumpy road. As electrons are forced through it, they constantly collide with the atoms of the material. These collisions convert the electrons' kinetic energy into thermal energy, causing the atoms to vibrate intensely, which we perceive as heat.

The Role of Electrical Resistance

Resistance is the measure of how much a material opposes the flow of electrical current. Materials with low resistance are called conductors, and they are used for wiring because they transfer electricity efficiently without significant heat loss.

Materials with high resistance are called resistors. A heating element is simply a specialized resistor designed not to control a signal, but to get as hot as possible. Its primary purpose is to impede the current and transform that electrical work into usable heat.

Characteristics of an Effective Heating Element

Not just any high-resistance material will work. An effective heating element must balance three critical properties to be reliable and long-lasting.

High Electrical Resistivity

First and foremost, the material must have a sufficiently high resistance to generate substantial heat with the applied voltage and current. Common choices include metallic alloys like Nichrome (nickel-chromium), which is found in everything from toasters to hair dryers.

High-Temperature Strength and Oxidation Resistance

The element must be able to operate at very high temperatures without melting, sagging, or degrading. Crucially, it must resist oxidation (reacting with oxygen in the air), which would cause it to burn out quickly. This is why a plain iron wire makes a poor heating element—it would rust and break down rapidly.

Mechanical and Thermal Stability

The material must withstand the physical stress of repeated thermal cycles—heating up and cooling down—without becoming brittle or cracking. Its resistance should also remain relatively stable across its operating temperature range to ensure consistent heat output.

Common Methods of Resistive Heating

Resistive heating is applied in two primary ways, depending on what is being heated.

Indirect Heating

This is the most common method. A separate heating element (like a Nichrome coil) gets hot and then transfers its heat to the target object or space via radiation (like in a toaster), convection (like in an oven fan), or conduction (like on an electric stovetop). The elements line the interior of the device but do not touch the substance being heated.

Direct Heating

In some industrial applications, the material being heated (the "charge") serves as the heating element itself. A massive electrical current is passed directly through the material, causing it to heat from within. This is extremely efficient for melting metals or other conductive materials, as the heat is generated exactly where it is needed.

Understanding the Trade-offs

While simple and effective, resistive heating is not without its limitations.

Efficiency vs. Operating Cost

Resistive heating is nearly 100% efficient at converting electrical watts into thermal watts. However, electricity is often a more expensive energy source than natural gas or oil. This can make resistive heating a costly choice for large-scale applications, like heating an entire building.

Thermal Lag

Heating elements take time to reach their target temperature and also take time to cool down. This inherent thermal lag can be a disadvantage in processes that require very precise or rapid temperature changes.

Element Lifespan

Even the best heating elements have a finite lifespan. Over hundreds or thousands of cycles, oxidation and thermal stress will eventually cause the element to fail, requiring replacement. The higher the operating temperature, the shorter the lifespan.

Making the Right Choice for Your Goal

Understanding these principles helps you recognize the best application for this technology.

- If your primary focus is simple design and portability: Resistive heating is ideal due to its lack of moving parts and straightforward construction, making it perfect for appliances like space heaters and toasters.

- If your primary focus is precise cooking or baking: The radiant and convective heat from indirect resistive elements provides the even, consistent temperatures required in electric ovens and cooktops.

- If your primary focus is high-efficiency industrial melting: Direct resistive heating can be the most effective method, provided the target material is electrically conductive.

By grasping the interplay between electricity and material science, you can effectively evaluate where this foundational heating technology excels.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Joule Heating: Electrical current through a high-resistance material generates heat. |

| Common Materials | Nichrome (Nickel-Chromium alloy) for high resistivity and oxidation resistance. |

| Heating Methods | Indirect (element heats target via radiation/convection) or Direct (current passes through material itself). |

| Primary Advantages | Near 100% efficiency, simple design, precise temperature control for applications like ovens. |

| Considerations | Electricity cost, thermal lag, finite element lifespan due to oxidation and thermal stress. |

Need a Reliable Heating Solution for Your Lab?

Understanding the principles of resistive heating is the first step. Selecting the right equipment is what ensures your processes run efficiently and reliably. KINTEK specializes in high-performance lab equipment, including furnaces and ovens built with durable heating elements designed for precision and longevity.

We provide solutions for:

- Consistent & Uniform Heating: Achieve precise temperature control for experiments and sample preparation.

- Durability at High Temperatures: Our equipment uses elements engineered to resist oxidation and thermal stress.

- Tailored to Your Application: Whether you need indirect heating for an oven or a direct heating solution, we can help.

Let's discuss your specific thermal requirements. Contact our experts today to find the perfect heating solution for your laboratory needs.

Visual Guide

Related Products

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- What material is used for furnace heating? Select the Right Element for Your Process

- Is molybdenum disulfide a heating element? Discover the best material for high-temperature applications.

- Which material is suitable for use in heating elements? Match the Right Material to Your Temperature and Atmosphere

- What is molybdenum disilicide used for? Powering High-Temperature Furnaces Up to 1800°C

- What are the properties of molybdenum heating element? Choose the Right Type for Your Furnace Atmosphere