At its core, heat treatment modifies a metal's strength by altering its internal crystal structure, known as its microstructure. Through controlled heating and cooling cycles, you can make a metal significantly harder and more resistant to deformation, or conversely, softer and more ductile. The specific outcome depends entirely on the chosen process and the intended application of the part.

The central purpose of heat treating is not simply to "increase strength," but to precisely engineer a metal's mechanical properties. It is a strategic manipulation of the trade-off between hardness (resistance to wear) and toughness (resistance to fracture) to achieve a desired performance characteristic.

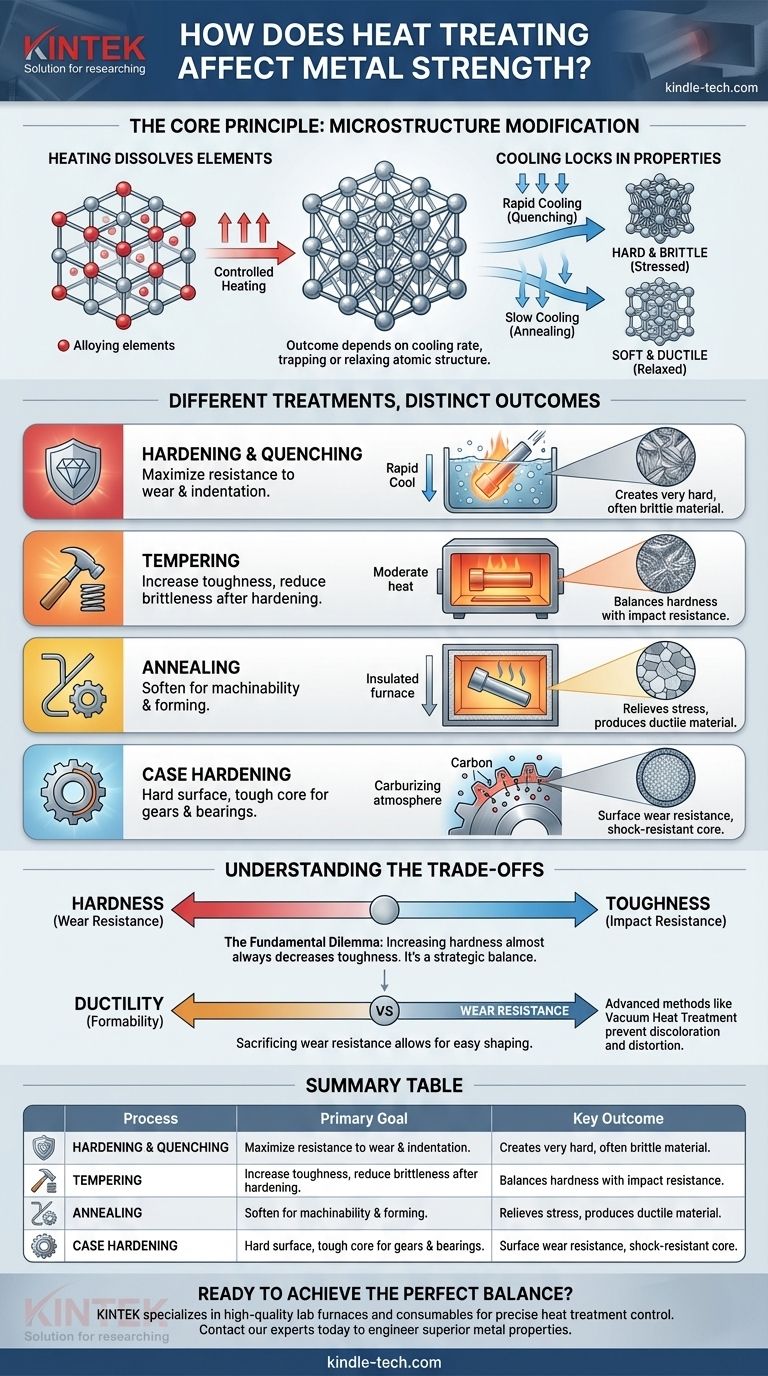

The Core Principle: Changing the Microstructure

Heat treatment works by manipulating the arrangement of atoms within a metal's crystalline lattice. The process generally involves heating the metal to a specific temperature, holding it there, and then cooling it at a controlled rate.

Heating Dissolves Elements

Heating a metal above a critical transformation temperature allows the atoms in its crystal structure to rearrange. Carbon and other alloying elements, which are normally locked in place, can dissolve and distribute more evenly throughout the material.

Cooling Locks in New Properties

The rate of cooling is what determines the final properties. This step locks the rearranged atomic structure in place, creating different microstructures with distinct mechanical characteristics.

- Rapid cooling (quenching) traps the atomic structure in a highly stressed, distorted state. This results in a very hard but often brittle material.

- Slow cooling (annealing) allows the atoms to settle into a more relaxed, organized state. This creates a softer, more ductile material that is easier to machine or form.

Different Treatments for Different Outcomes

The term "strength" can be misleading because it encompasses several distinct properties. Different heat treatments are designed to optimize for one property, often at the expense of another.

Increasing Hardness (Hardening & Quenching)

This is what most people think of when they hear about strengthening metal. The goal is to maximize the metal's resistance to indentation, scratching, and wear. It is achieved through rapid cooling, or quenching, from a high temperature.

Increasing Toughness (Tempering)

A metal that has been hardened is often too brittle for practical use, meaning it can shatter under impact. Tempering is a secondary, lower-temperature heat treatment performed after quenching to reduce some of that brittleness and increase toughness, which is the ability to absorb energy and deform without fracturing.

Softening for Workability (Annealing)

Sometimes, the goal is to make a metal weaker and more workable. Annealing involves heating a metal and then letting it cool very slowly. This process relieves internal stresses and produces a soft, ductile material that can be easily machined, stamped, or formed.

Surface-Level Strength (Case Hardening)

For parts like gears or bearings, you need a very hard, wear-resistant surface but a softer, tougher core that can withstand shock. Case hardening (or carburising) is a process that introduces carbon into the surface layer of a low-carbon steel, allowing the surface to be hardened while the core remains tough and ductile.

Understanding the Trade-offs

Choosing a heat treatment process is always an exercise in balancing competing properties. It is impossible to maximize every desirable characteristic at once.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off in metallurgy. As you increase a metal's hardness, you almost always decrease its toughness, making it more brittle. A file is extremely hard and holds an edge, but it will shatter if dropped on a concrete floor.

Sacrificing Wear Resistance for Ductility

Conversely, a very soft and ductile metal (like one that has been annealed) can be bent and shaped easily without cracking. However, it will have very poor resistance to wear and abrasion.

Process Benefits and Complexity

Advanced methods like vacuum heat treatment offer significant advantages, such as preventing surface discoloration and reducing part distortion. This can eliminate the need for costly secondary cleaning or finishing operations, but the process itself can be more complex and expensive.

Matching the Treatment to Your Goal

The right heat treatment is the one that produces the ideal balance of properties for the component's specific function.

- If your primary focus is wear resistance and cutting edges: Hardening through quenching is the primary choice, followed by a light temper.

- If your primary focus is impact resistance and preventing fracture: Tempering after hardening is essential to impart the necessary toughness.

- If your primary focus is easy machining or forming: Annealing is the correct process to soften the metal before any fabrication work begins.

- If your primary focus is a durable surface with a shock-resistant core: Case hardening is the ideal solution for components like gears and shafts.

Ultimately, heat treatment transforms a simple piece of metal into a highly engineered component with properties tailored for its precise purpose.

Summary Table:

| Heat Treatment Process | Primary Goal | Key Outcome |

|---|---|---|

| Hardening & Quenching | Increase Hardness & Wear Resistance | Creates a very hard, but brittle, material. |

| Tempering | Increase Toughness | Reduces brittleness in a hardened metal, improving impact resistance. |

| Annealing | Soften for Workability | Produces a soft, ductile metal that is easy to machine or form. |

| Case Hardening | Surface Hardness with Tough Core | Creates a hard, wear-resistant surface layer over a tough, ductile core. |

Ready to achieve the perfect balance of strength, hardness, and toughness for your metal components? The right lab equipment is critical for precise heat treatment processes. KINTEK specializes in high-quality lab furnaces and consumables that deliver the exact temperature control and uniform heating your R&D or production needs. Contact our experts today to discuss how our solutions can help you engineer superior metal properties.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals

- What is the leak rate for a vacuum furnace? Ensure Process Purity and Repeatability

- How to vacuum out a furnace? A Step-by-Step Guide to Safe DIY Maintenance

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment