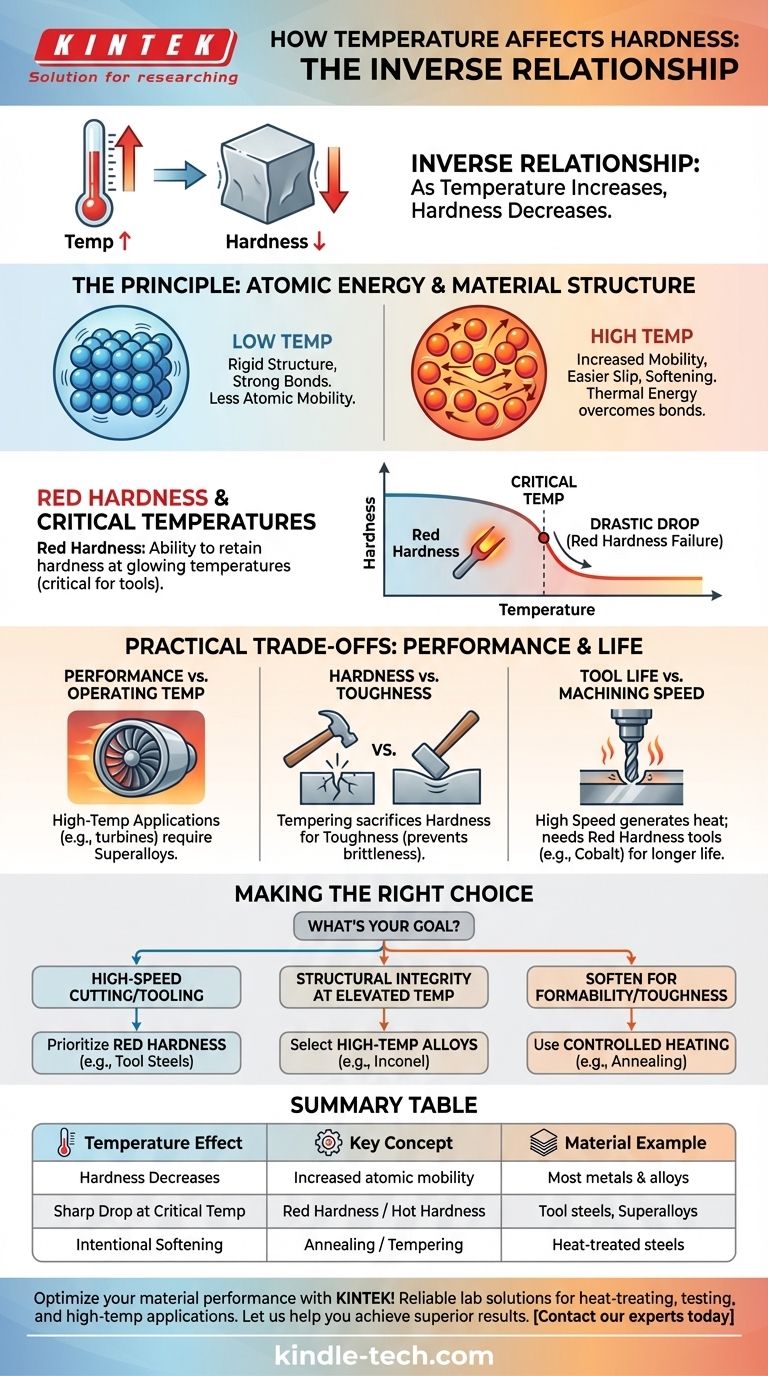

In nearly all materials, hardness has an inverse relationship with temperature. As a material's temperature increases, its hardness decreases. For many materials, especially complex alloys, this decline is not gradual; there is a critical temperature at which a drastic drop in hardness occurs, a property known as "red hardness" or "hot hardness."

The fundamental reason materials soften when heated is increased atomic mobility. Heat provides the energy that allows atoms within the material's crystal structure to move and slip past one another more easily, reducing the material's resistance to permanent deformation.

The Principle: Atomic Energy and Material Structure

To understand why heat softens a material, we must look at it on a microscopic level. The core concepts are atomic bonds and thermal energy.

Hardness at the Atomic Level

Hardness is a measure of a material's resistance to localized plastic deformation, such as a scratch or an indentation. At its core, this resistance comes from the strength of the atomic bonds holding the material's crystal lattice together. A hard material has a rigid structure that strongly resists any attempt to permanently displace its atoms.

The Role of Thermal Energy

Heat is simply a form of energy that causes atoms to vibrate in place. As you add more heat, the atoms vibrate more intensely. This increased vibrational energy makes it easier for atoms to overcome the bonding forces holding them in a fixed position.

The Impact on Crystal Structure

When a force is applied (for example, by a hardness tester's indenter), the added thermal energy helps atoms slip past one another into new positions. This atomic slip is the mechanism of plastic deformation. Because the atoms move more easily at higher temperatures, the material deforms with less applied force, registering as a lower hardness value.

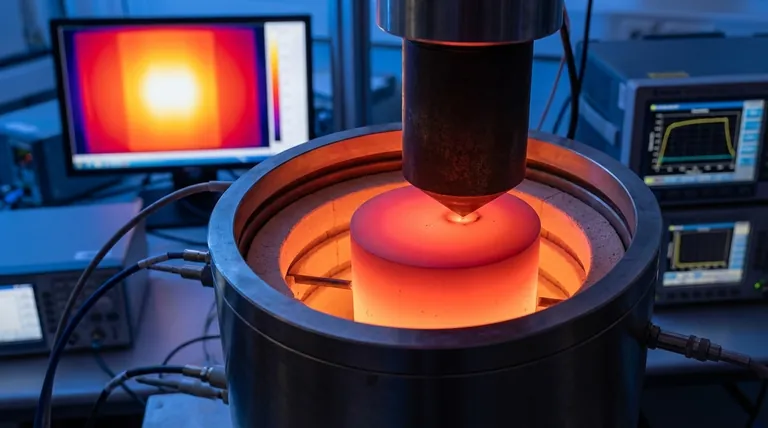

Understanding "Red Hardness" and Critical Temperatures

The relationship between temperature and hardness is not always a simple, straight line. Certain materials exhibit sharp changes in behavior at specific temperature thresholds.

What is "Red Hardness"?

Red hardness (or hot hardness) is the ability of a material, particularly tool steels and superalloys, to retain its hardness at temperatures high enough to cause it to glow. This property is critical in applications like high-speed machining, where the tool tip can reach extreme temperatures due to friction. A tool without sufficient red hardness will quickly soften, dull, and fail.

The Point of Drastic Change

In heat-treated alloys, hardness is achieved by locking the atomic structure into a specific, highly-strained configuration (like martensite in steel). Heating provides the energy for this unstable structure to relax into a more stable, softer form. This transformation can happen rapidly above a certain temperature, causing the "drastic change" in hardness mentioned in the reference.

Understanding the Trade-offs

The effect of temperature on hardness is not just a scientific curiosity; it is a central factor in material science and engineering with significant practical consequences.

Performance vs. Operating Temperature

Engineers must always consider the operating environment. A material that is exceptionally hard at room temperature may be completely unsuitable for a high-temperature application, like a jet engine turbine blade. This necessitates the use of specialized superalloys designed to maintain their mechanical properties under extreme heat.

Hardness vs. Toughness

The relationship is also used intentionally during heat treatment. Processes like tempering involve carefully heating a very hard, brittle steel to a specific temperature. This intentionally sacrifices some hardness to relieve internal stresses and increase toughness, preventing the material from being too fragile for its intended use.

Tool Life vs. Machining Speed

In manufacturing, there is a constant trade-off between the speed of an operation and the life of the cutting tool. Pushing for higher speeds generates more heat. This requires investing in tool materials with superior red hardness, such as those containing cobalt or tungsten, or using ceramic cutters, which are stable at even higher temperatures.

Making the Right Choice for Your Goal

Selecting a material or process requires a clear understanding of your primary objective. How you leverage the relationship between temperature and hardness depends entirely on your desired outcome.

- If your primary focus is high-speed cutting or tooling: Prioritize materials with a high "red hardness" rating to ensure the tool edge remains effective under extreme friction-induced heat.

- If your primary focus is structural integrity at elevated temperatures: You must select alloys specifically designed for high-temperature service (e.g., Inconel, Hastelloy) by consulting their temperature-dependent mechanical property charts.

- If your primary focus is to soften a material for formability or increased toughness: Use controlled heating processes like annealing or tempering, understanding that you are intentionally trading hardness for other desirable mechanical properties.

Understanding the interplay between temperature and hardness is fundamental to designing, selecting, and processing materials for reliable performance.

Summary Table:

| Temperature Effect | Key Concept | Material Example |

|---|---|---|

| Hardness Decreases | Increased atomic mobility | Most metals & alloys |

| Sharp Drop at Critical Temp | Red Hardness / Hot Hardness | Tool steels, Superalloys |

| Intentional Softening | Annealing / Tempering | Heat-treated steels |

Optimize your material performance with KINTEK!

Understanding the precise relationship between temperature and hardness is critical for selecting the right lab equipment and consumables. Whether you are heat-treating alloys, testing material properties, or developing high-temperature applications, KINTEK specializes in providing reliable lab solutions to meet your needs.

Let us help you achieve superior results. Contact our experts today to discuss how our products can enhance your laboratory's efficiency and accuracy.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is sputter coating used for? Achieve Superior Thin Films for Electronics, Optics, and Tools

- What is the sputtering yield of materials? Master Deposition Rates & Film Quality

- What are the advantages and applications of sintering process? Achieve Strong, Complex Parts Efficiently

- Are biomass fuels sustainable? Uncover the truth behind carbon neutrality and lifecycle impacts.

- What is the alternative to KBr in IR? Choosing the Right Sample Matrix for Accurate Spectroscopy

- What are the methods of synthesis of nanomaterials? Top-Down vs. Bottom-Up Approaches Explained

- Does higher heat capacity mean higher melting point? Unraveling the Critical Difference

- What is the product of physical vapor deposition? A High-Performance Thin Film Coating