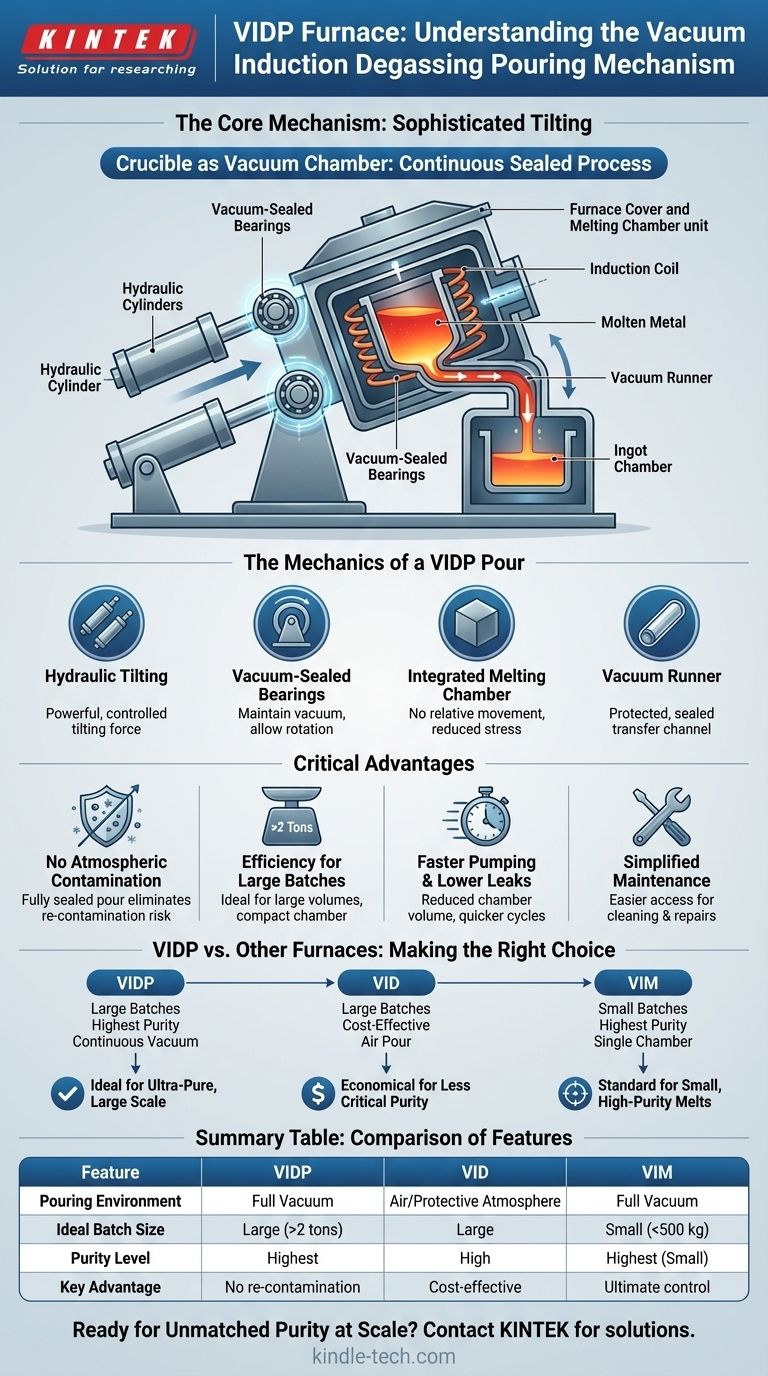

At its core, the pouring mechanism of a Vacuum Induction Degassing Pouring (VIDP) furnace is a sophisticated tilting system. It uses two hydraulic cylinders to pivot the furnace cover, which in turn drives the entire melting chamber to tilt around specially designed vacuum-sealed bearings. This allows molten metal to flow through a sealed vacuum runner into an ingot chamber, all without breaking the vacuum.

The critical innovation of the VIDP furnace isn't just the tilting motion, but the underlying principle: the crucible itself serves as the vacuum chamber. This design ensures the entire process—from melting and degassing to pouring—occurs in an uninterrupted vacuum, which is essential for producing large volumes of ultra-pure metals.

The Mechanics of a VIDP Pour

The elegance of the VIDP system lies in how it maintains a perfect seal while performing the complex mechanical action of pouring. Each component is engineered to work in concert to protect the refined metal.

The Hydraulic Tilting System

The process is initiated by two powerful hydraulic cylinders. These cylinders are connected to the furnace cover, providing the force needed to tilt the entire melting assembly in a smooth, controlled manner.

The Vacuum-Sealed Bearings

The furnace cover and melting chamber pivot around specialized vacuum-sealed bearings. These are the lynchpin of the design, allowing for rotational movement while preventing any atmospheric gases from entering the system. The integrity of these seals is paramount.

The Integrated Melting Chamber

A key design feature is that there is no relative movement between the melting chamber and the induction coil crucible during the pour. The cover, chamber, and crucible tilt as a single, unified block. This prevents mechanical stress and ensures the refined metal's journey is undisturbed.

The Vacuum Runner

As the furnace tilts, the molten metal doesn't simply spill out. It flows through a purpose-built, sealed channel known as a vacuum runner. This runner connects the melting chamber directly to the ingot chamber, acting as a protected transfer tube that maintains the vacuum environment.

Why This Design is a Critical Advantage

The VIDP's pouring mechanism directly addresses the core challenges of large-scale, high-purity metal production. It offers distinct advantages over older vacuum furnace technologies.

Eliminating Atmospheric Contamination

The primary goal of vacuum metallurgy is to remove dissolved gases like oxygen and hydrogen. A standard Vacuum Induction Degassing (VID) furnace can achieve this during melting but may pour the metal in air or a protective atmosphere, reintroducing the risk of contamination. The VIDP's fully sealed pour eliminates this risk entirely.

Unprecedented Efficiency for Large Batches

For charge weights above two tons, building a traditional Vacuum Induction Melting (VIM) furnace, where the entire apparatus sits inside one massive chamber, becomes highly inefficient. The VIDP design solves this by making the crucible itself the compact vacuum chamber.

Faster Pumping and Lower Leak Rates

This drastically reduced chamber volume leads to significant benefits. The vacuum pumps can evacuate the small space much faster, shortening the overall production cycle. Furthermore, a smaller chamber has fewer potential leak points, simplifying leak detection and repair.

Simplified Maintenance

The compact and accessible structure of the VIDP furnace makes routine tasks easier. Internal cleaning is faster, and critical components like the thermocouple used for temperature measurement can be replaced with minimal downtime.

Understanding the Trade-offs: VIDP vs. Other Furnaces

No single technology is perfect for every application. The choice between VIDP, VID, and VIM depends entirely on the required purity, batch size, and economic constraints.

VIDP vs. VID (Vacuum Induction Degassing)

A standard VID furnace is a simpler, more cost-effective system. It excels at melting and degassing but lacks the integrated vacuum pouring of a VIDP. It is suitable for alloys where the highest possible purity is not the primary driver and some exposure during pouring is acceptable.

VIDP vs. VIM (Vacuum Induction Melting)

A traditional VIM furnace encloses the crucible and the ingot mold in a single large vacuum chamber. This is the gold standard for producing small-capacity (5-500 kg) batches of extremely pure alloys. However, for large capacities, the chamber size becomes a major liability in terms of cost, pump-down time, and maintenance. The VIDP was developed specifically to overcome this large-scale limitation.

Making the Right Choice for Your Goal

Selecting the correct vacuum process requires a clear understanding of your end goal.

- If your primary focus is producing large batches (>2 tons) of alloys with the absolute highest purity: The VIDP process is superior because it maintains a vacuum from melting through pouring, preventing any re-contamination.

- If your primary focus is cost-effective degassing for applications that can tolerate pouring in air: A standard VID furnace offers a more economical solution by simplifying the pouring stage.

- If your primary focus is producing smaller, high-purity batches (<500 kg) in a highly controlled environment: A traditional VIM furnace, where both melt and mold are in one chamber, remains the industry standard.

Understanding these distinct pouring philosophies is the key to selecting the most effective and economical technology for your metallurgical goals.

Summary Table:

| Feature | VIDP Furnace | VID Furnace | VIM Furnace |

|---|---|---|---|

| Pouring Environment | Full vacuum | Air or protective atmosphere | Full vacuum |

| Ideal Batch Size | Large (>2 tons) | Large | Small (<500 kg) |

| Purity Level | Highest | High | Highest (for small batches) |

| Key Advantage | No re-contamination during pour | Cost-effective degassing | Ultimate control for small melts |

Ready to Achieve Unmatched Metal Purity at Scale?

Producing large volumes of ultra-pure metals requires precision equipment designed for performance and reliability. KINTEK specializes in advanced lab equipment and consumables, providing solutions like the VIDP furnace to meet the demanding needs of modern metallurgy.

Our expertise ensures you get the right technology to eliminate contamination, improve efficiency, and achieve your production goals. Let's discuss how we can support your laboratory's success.

Contact KINTEK today for a personalized consultation

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity