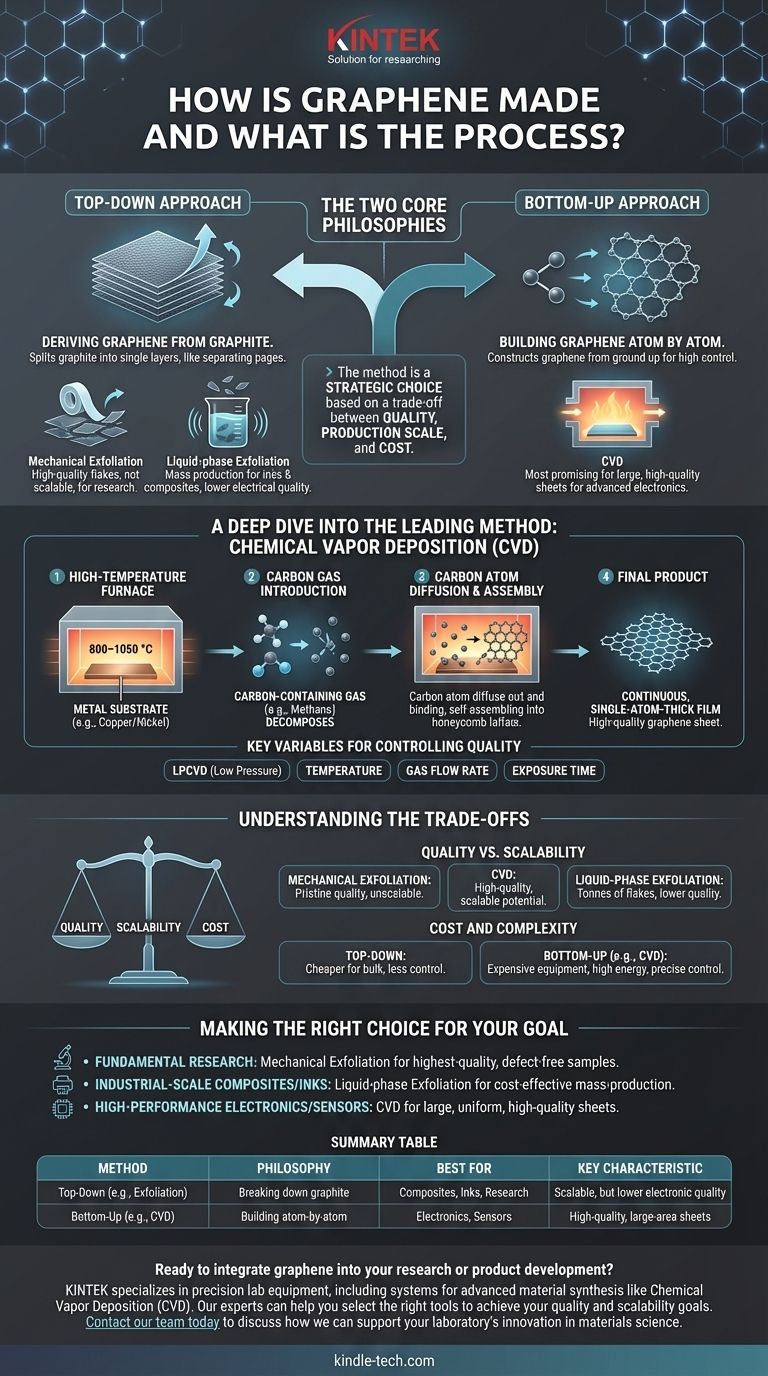

At its core, graphene is produced using two opposing strategies. The first is a "top-down" approach that splits graphite into single layers, while the second is a "bottom-up" method that builds the graphene sheet atom by atom. Among these, Chemical Vapor Deposition (CVD) has emerged as the most promising technique for creating the large, high-quality sheets required for advanced electronics.

The method used to create graphene is not a matter of one being universally better, but a strategic choice based on a fundamental trade-off between the final product's quality, production scale, and cost.

The Two Core Philosophies of Graphene Production

Understanding how graphene is made begins with understanding the two fundamental approaches. Each philosophy serves different end goals, from small-scale research to industrial mass production.

The "Top-Down" Approach: Deriving Graphene from Graphite

This method starts with bulk graphite and breaks it down into its constituent single-atom-thick layers. It's conceptually similar to separating pages from a thick book.

The most famous example is mechanical exfoliation, famously done with simple adhesive tape to lift a single layer of graphene. While this produces extremely high-quality flakes, it is not scalable and is primarily used for fundamental research.

Another top-down method is liquid-phase exfoliation. This process uses liquids and energy (like sonication) to separate graphite into graphene flakes, making it more suitable for mass production of graphene inks and composites, though the electrical quality is often lower.

The "Bottom-Up" Approach: Building Graphene Atom by Atom

This strategy constructs graphene from the ground up by assembling individual carbon atoms on a substrate. This provides a much higher degree of control over the final product's quality and size.

This category includes methods like arc discharging and epitaxial growth, but the most important and widely used technique is Chemical Vapor Deposition (CVD).

A Deep Dive into the Leading Method: Chemical Vapor Deposition (CVD)

For applications that demand large, uniform sheets of high-quality graphene, such as in semiconductors and transparent displays, CVD is the industry-leading process.

How the CVD Process Works

The CVD process takes place inside a high-temperature furnace. A metal substrate, typically copper or nickel foil, is heated to around 800–1050 °C.

A carbon-containing gas, such as methane, is then introduced into the chamber. The extreme heat causes the hydrocarbon gas to decompose, releasing individual carbon atoms.

These carbon atoms then diffuse and bind onto the surface of the hot metal substrate, self-assembling into the signature honeycomb lattice structure of graphene. This forms a continuous, single-atom-thick film across the entire substrate.

Key Variables for Controlling Quality

The final quality of CVD graphene is highly dependent on precise control over the reaction environment. Most systems use low-pressure chemical vapor deposition (LPCVD), as lower pressures help prevent unwanted side reactions and produce a more uniform film.

Engineers carefully adjust variables like temperature, gas flow rate, and exposure time to control the graphene's layer thickness and crystal quality, ensuring the final product meets exact specifications.

Understanding the Trade-offs

There is no single "best" way to make graphene. The choice of production method is a critical decision dictated by the intended application and its specific requirements.

Quality vs. Scalability

Methods like mechanical exfoliation produce pristine, defect-free graphene perfect for lab research but are impossible to scale.

Conversely, liquid-phase exfoliation can produce tonnes of graphene flakes for use in composites or inks, but the individual flakes have more defects and lower electrical performance. CVD sits in the middle, offering a path to high-quality, large-area sheets with scalable potential.

Cost and Complexity

High-temperature processes like CVD or the sublimation of silicon carbide require expensive, specialized equipment and significant energy input.

Top-down methods can be less complex and cheaper to implement for bulk production, but they sacrifice the precise control over quality that bottom-up methods provide.

Making the Right Choice for Your Goal

Selecting a graphene production method requires aligning the process capabilities with your primary objective.

- If your primary focus is fundamental research: Mechanical exfoliation remains the gold standard for producing the highest-quality, defect-free samples for scientific study.

- If your primary focus is industrial-scale composites or inks: Liquid-phase exfoliation offers the most cost-effective path to mass-producing graphene flakes in large quantities.

- If your primary focus is high-performance electronics or sensors: Chemical Vapor Deposition (CVD) is the most viable method for growing the large, uniform, and high-quality graphene sheets required.

Ultimately, the journey from a carbon source to a final graphene product is a carefully engineered process tailored to its intended purpose.

Summary Table:

| Method | Philosophy | Best For | Key Characteristic |

|---|---|---|---|

| Top-Down (e.g., Exfoliation) | Breaking down graphite | Composites, Inks, Research | Scalable, but lower electronic quality |

| Bottom-Up (e.g., CVD) | Building atom-by-atom | Electronics, Sensors | High-quality, large-area sheets |

Ready to integrate graphene into your research or product development? The right production method is critical to your success. KINTEK specializes in precision lab equipment, including systems for advanced material synthesis like Chemical Vapor Deposition (CVD). Our experts can help you select the right tools to achieve your quality and scalability goals. Contact our team today to discuss how we can support your laboratory's innovation in materials science.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How do CVD diamonds grow? A Step-by-Step Guide to Lab-Grown Diamond Creation

- How do you calculate coating coverage? A Practical Guide to Accurate Material Estimation

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is the process of coating deposition? A Step-by-Step Guide to Thin Film Engineering

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies