At its core, powder metallurgy (PM) is fundamentally different because it is an additive, or "net-shape," manufacturing process that builds parts by compacting and heating metal powders. Unlike traditional machining, which cuts material away from a solid block, or casting, which starts with molten metal, PM constructs parts from the ground up, resulting in minimal waste and the ability to create unique material blends.

The critical distinction to grasp is that powder metallurgy is not just another way to shape metal. It's a process of material creation and part formation happening simultaneously, offering unparalleled control over material composition and part complexity for high-volume production.

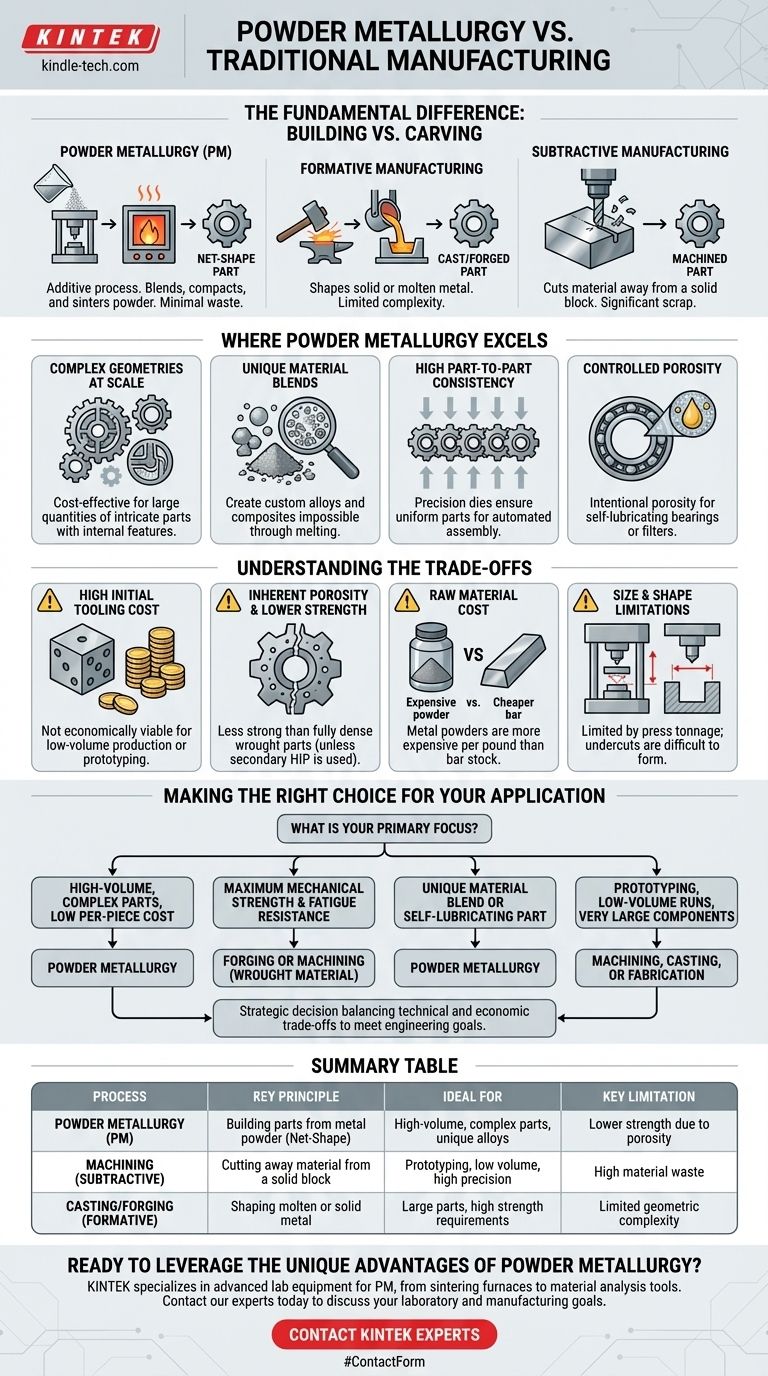

The Fundamental Difference: Building vs. Carving

To understand powder metallurgy, it's best to compare its core philosophy to that of other major manufacturing families.

Powder Metallurgy (PM): A "Net-Shape" Process

The PM process involves three primary steps: blending metal powders, compacting them into a desired shape using a die, and heating (sintering) them in a controlled atmosphere furnace to bond the particles together.

This process forms a solid part that is very close to its final dimensions right out of the furnace, hence the term net-shape or near-net-shape.

Subtractive Manufacturing: Carving from a Block

Processes like CNC machining are subtractive. They start with a solid block or bar of material and methodically cut away everything that isn't the final part.

While incredibly precise, this method generates significant scrap material, which can be costly, especially with expensive metals.

Formative Manufacturing: Shaping Solid or Liquid Metal

This category includes forging and casting. Forging uses immense pressure to shape a solid piece of hot metal, while casting involves pouring molten metal into a mold.

These are excellent for producing strong or large parts, but they often have limitations in geometric complexity and may require extensive secondary machining to achieve final specifications.

Where Powder Metallurgy Excels

PM's unique approach provides distinct advantages that make it the ideal choice for specific applications.

Complex Geometries at Scale

PM is exceptionally cost-effective for producing large quantities of small, intricate parts. Creating complex internal features or gear teeth through machining is time-consuming and wasteful, but with PM, these features are pressed directly into the part from the start.

Unique Material Blends

This is a key differentiator. PM allows you to create custom alloys and composites that are impossible to produce through melting and casting. You can blend different metals, or even metals and ceramics, to achieve specific properties like high wear resistance with self-lubrication.

High Part-to-Part Consistency

The use of durable, precision-machined dies ensures that every part produced is virtually identical. This high degree of part-to-part uniformity is critical for automated assembly lines and applications requiring tight tolerances across millions of components.

Controlled Porosity

While often seen as a downside, the inherent porosity of standard PM parts can be a design advantage. This porosity can be intentionally controlled and used to create self-lubricating bearings (by impregnating the part with oil) or filters.

Understanding the Trade-offs

No process is perfect. Objectivity requires acknowledging PM's limitations.

High Initial Tooling Cost

The hardened steel or carbide dies required for compaction are expensive to design and manufacture. This makes PM economically unviable for low-volume production or prototyping.

Inherent Porosity and Lower Strength

Standard sintered PM parts are not 100% dense. This residual porosity makes them less strong than parts that are forged or machined from a fully dense wrought bar. While secondary processes like Hot Isostatic Pressing (HIP) can create fully dense PM parts, this adds significant cost.

Raw Material Cost

Finely atomized metal powders are more expensive per pound than the equivalent raw bar stock or ingot used in other processes. The cost savings in PM come from the elimination of waste and machining, not from cheaper material.

Size and Shape Limitations

Part size is limited by the tonnage of the compaction press. Furthermore, features like undercuts or holes perpendicular to the pressing direction are difficult or impossible to form and require secondary operations.

Making the Right Choice for Your Application

Selecting the correct manufacturing process depends entirely on your project's specific priorities of cost, volume, material properties, and complexity.

- If your primary focus is high-volume, complex parts at a low per-piece cost: Powder metallurgy is often the most economical and efficient choice.

- If your primary focus is maximum mechanical strength and fatigue resistance: Forging or machining from a solid wrought material is typically the superior option.

- If your primary focus is creating a unique material blend or a self-lubricating part: Powder metallurgy may be the only technologically viable path.

- If your primary focus is prototyping, low-volume runs, or very large components: Machining, casting, or fabrication are generally more practical and cost-effective.

Ultimately, choosing a manufacturing process is a strategic decision based on balancing these technical and economic trade-offs to meet your specific engineering goal.

Summary Table:

| Process | Key Principle | Ideal For | Key Limitation |

|---|---|---|---|

| Powder Metallurgy (PM) | Building parts from metal powder (Net-Shape) | High-volume, complex parts, unique alloys | Lower strength due to porosity |

| Machining (Subtractive) | Cutting away material from a solid block | Prototyping, low volume, high precision | High material waste |

| Casting/Forging (Formative) | Shaping molten or solid metal | Large parts, high strength requirements | Limited geometric complexity |

Ready to leverage the unique advantages of powder metallurgy for your high-volume component needs?

KINTEK specializes in providing the advanced lab equipment and consumables—from sintering furnaces to material analysis tools—that are essential for developing and optimizing PM processes. Our expertise helps you achieve the material properties and production efficiency your application demands.

Contact our experts today to discuss how we can support your laboratory and manufacturing goals.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Automatic Laboratory Heat Press Machine

People Also Ask

- What are the disadvantages of centrifugal separators? High Costs and Performance Limitations

- Why is an ultrasonic cleaner used with ethanol to treat alloy specimens? Ensure Superior Diffusion Bonding Results

- Why is potassium bromide used as a reference compound in IR spectroscopy? Unlock Clear, Interference-Free Sample Analysis

- What is the difference between pyrolysis and incineration? Material Recovery vs. Energy Recovery

- What is the temperature of sintering heating? It Depends on Your Material's Melting Point

- How does biomass compare to other renewable sources? Unlocking On-Demand Power for Grid Stability

- What are the limitations of melting point determination? Understand Purity, Technique, and Material Behavior

- What is the acceptable pressure drop across a filter? Master Your System's Health and Efficiency