In magnetron sputtering, plasma is the energized medium that makes the entire coating process possible. It is created by applying a high voltage between two electrodes—a cathode holding the target material and an anode—within a vacuum chamber filled with a low-pressure gas, typically argon. This electric field accelerates free electrons, which then collide with and ionize the gas atoms, initiating a self-sustaining cascade that forms the plasma.

The generation of plasma in magnetron sputtering is fundamentally a controlled chain reaction. It begins with a powerful electric field that energizes a few free electrons, which then collide with neutral gas atoms, creating a dense, self-sustaining population of positive ions and more electrons that becomes the engine for the sputtering process.

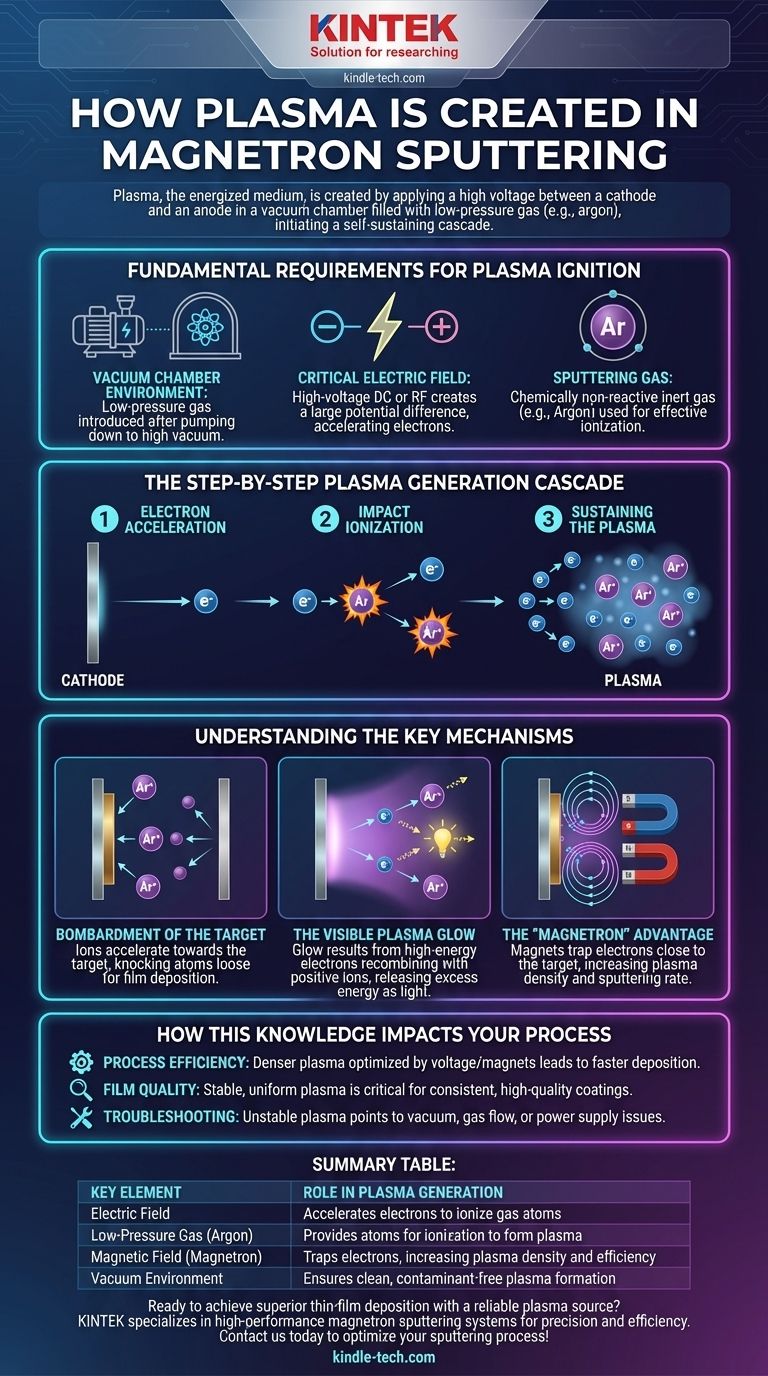

The Fundamental Requirements for Plasma Ignition

To create a stable plasma, three initial conditions must be met inside the sputtering chamber. These elements work in concert to transform a neutral gas into an ionized, reactive state.

The Vacuum Chamber Environment

First, the chamber is pumped down to a high vacuum to remove air and other contaminants. Then, a small, precisely controlled amount of a process gas is introduced, creating a low-pressure environment.

The Critical Electric Field

A high-voltage DC or RF power supply creates a large potential difference between the cathode (which holds the target material and is negatively charged) and the anode (often the chamber walls and substrate holder, which are grounded). This powerful electric field is the primary driver of the entire process.

The Sputtering Gas

An inert gas, most commonly argon (Ar), is used. Argon is chosen because it is chemically non-reactive and has a suitable atomic mass for effectively dislodging atoms from the target, yet it can be ionized with relative ease by the electric field.

The Step-by-Step Plasma Generation Cascade

Once the initial conditions are set, the creation of plasma occurs in a rapid, self-sustaining sequence of events.

Step 1: Electron Acceleration

The strong electric field immediately accelerates the few free electrons that are naturally present in the gas, propelling them away from the negative cathode at high speed.

Step 2: Impact Ionization

As these high-energy electrons travel through the chamber, they collide with neutral argon atoms. If the collision is energetic enough, it knocks an electron out of the argon atom's orbit.

This single event creates two new charged particles: a new free electron and a positively charged argon ion (Ar+).

Step 3: Sustaining the Plasma

The newly created electron is also accelerated by the electric field, leading to more collisions and more ionization. This cascade effect quickly generates a dense, stable cloud of positive ions and free electrons, which is the plasma.

Understanding the Key Mechanisms

The plasma itself does not deposit the film. Instead, it serves as the source of ions that do the work of sputtering. The visible glow is merely a side effect of this activity.

The Bombardment of the Target

While the electrons are accelerated away from the cathode, the much heavier, positively charged argon ions are accelerated towards the negatively charged cathode target. They strike the target surface with immense kinetic energy.

This high-energy bombardment physically knocks atoms loose from the target material. These ejected atoms then travel through the chamber and deposit onto the substrate, forming the thin film.

The Visible Plasma Glow

The characteristic glow seen during sputtering is not the sputtering event itself. It is produced when high-energy free electrons recombine with the positive argon ions, causing them to return to a lower energy state. The excess energy is released as photons of light, creating the visible glow.

The "Magnetron" Advantage

In magnetron sputtering specifically, powerful magnets are placed behind the cathode target. These magnets generate a magnetic field that traps the highly mobile electrons in a circular path close to the target's surface.

This trapping mechanism dramatically increases the probability that an electron will collide with an argon atom before being lost to the anode. This creates a much denser, more intense plasma right where it is needed, leading to higher sputtering rates and a more efficient process that can operate at lower gas pressures.

How This Knowledge Impacts Your Process

Understanding how plasma is formed is essential for controlling and troubleshooting your thin-film deposition process.

- If your primary focus is process efficiency: Realize that a denser plasma, achieved by optimizing voltage and magnetic field strength, directly leads to a higher ion bombardment rate and a faster deposition.

- If your primary focus is film quality: A stable and uniform plasma is absolutely critical for depositing a consistent, homogenous, and high-quality coating onto your substrate.

- If you are troubleshooting your system: An unstable, weak, or non-existent plasma points directly to a problem with one of the three core requirements: the vacuum level, the gas flow, or the power supply providing the voltage.

By mastering the principles of plasma generation, you gain direct control over the quality and efficiency of your thin-film deposition.

Summary Table:

| Key Element | Role in Plasma Generation |

|---|---|

| Electric Field | Accelerates electrons to ionize gas atoms |

| Low-Pressure Gas (Argon) | Provides atoms for ionization to form plasma |

| Magnetic Field (Magnetron) | Traps electrons, increasing plasma density and efficiency |

| Vacuum Environment | Ensures clean, contaminant-free plasma formation |

Ready to achieve superior thin-film deposition with a reliable plasma source? KINTEK specializes in high-performance lab equipment, including magnetron sputtering systems designed for precision and efficiency. Whether you're focused on research or production, our solutions ensure stable plasma generation for consistent, high-quality coatings. Contact us today to discuss how we can optimize your sputtering process!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 304 316 Stainless Steel Vacuum Ball Valve Stop Valve for High Vacuum Systems

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications