Operating an electric arc furnace is a cyclical process centered on transforming solid scrap metal into molten steel using immense electrical energy. The fundamental steps involve charging the furnace with scrap, melting it down with a powerful electric arc, refining the molten bath, and tapping the finished liquid steel.

The core of EAF operation is not merely a sequence of steps, but a highly controlled industrial process that harnesses extreme temperatures to melt and chemically refine scrap metal inside a durable, refractory-lined vessel.

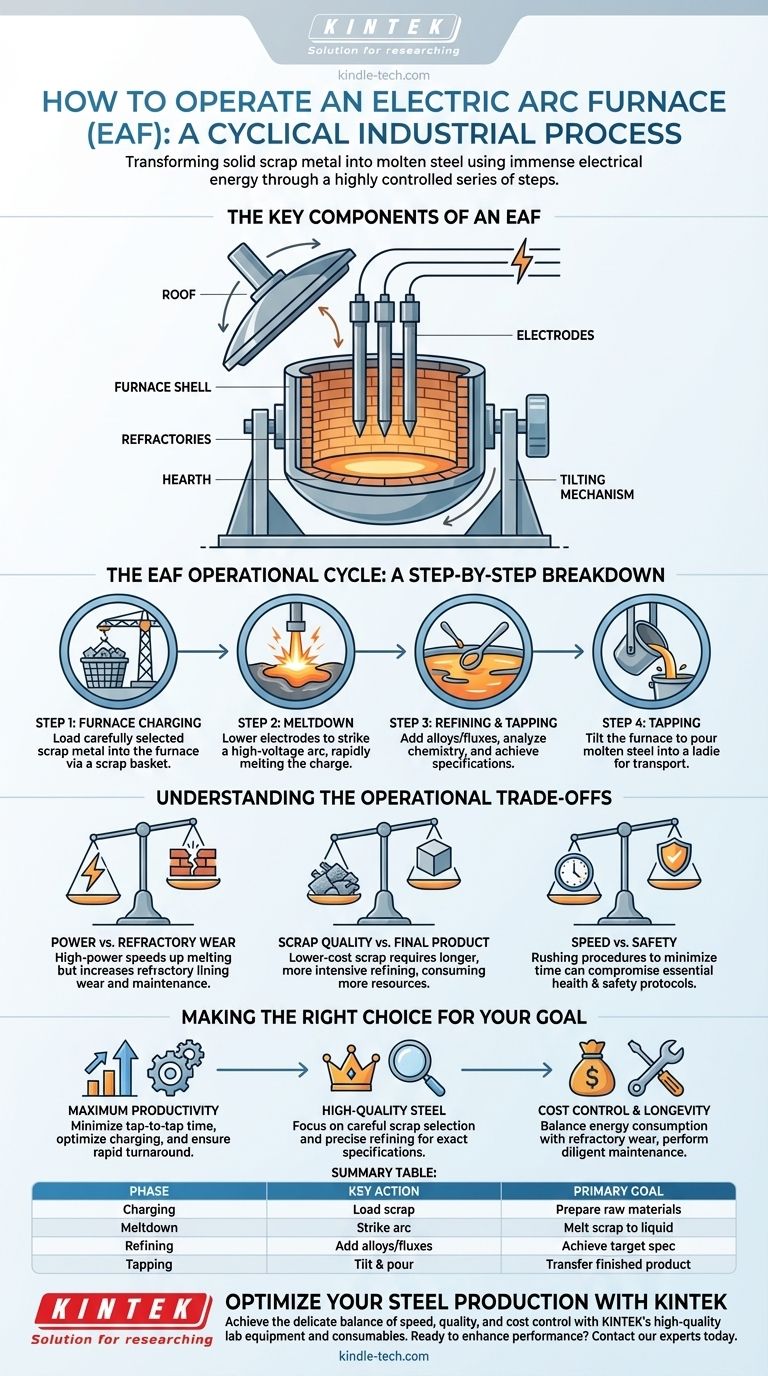

The Key Components of an EAF

To understand the operation, you must first understand the machine. The EAF is a robust system designed to contain and control a violent melting process.

The Furnace Shell and Hearth

The main body of the furnace is a large, cylindrical steel shell. This shell is lined with specialized heat-resistant bricks known as refractories.

The bottom of the furnace, called the hearth, is where the molten steel collects before being poured out.

The Roof and Electrodes

The EAF has a removable, water-cooled roof that swings away to allow scrap to be loaded from above.

The roof has three holes through which massive graphite or carbon electrodes are lowered. These electrodes deliver the electricity that melts the metal.

The Tilting Mechanism

The entire furnace shell is mounted on a rocking mechanism or cradle. This allows the furnace to be tilted forward to pour out, or "tap," the finished steel and tilted backward to remove slag.

The EAF Operational Cycle: A Step-by-Step Breakdown

The complete process from one batch of steel to the next is known as the "tap-to-tap" cycle. It consists of several distinct phases.

Step 1: Furnace Charging

First, carefully selected scrap metal is loaded into a large "scrap basket."

The furnace roof is swung aside, and the basket is positioned over the furnace. The bottom of the basket opens, charging the EAF with the raw material.

Step 2: Meltdown

The roof is moved back into place, and the electrodes are lowered into the furnace until they are just above the scrap.

A high-voltage, high-current arc is struck between the electrodes and the scrap metal. This generates intense heat, rapidly melting the charge from the top down.

Step 3: Refining and Tapping

Once the scrap is molten, the process shifts from melting to refining. Samples are taken to analyze the steel's chemistry.

Alloys and fluxes are added to the molten bath to adjust its chemical composition and remove impurities. When the steel meets the required specification, the furnace is tilted. The molten steel is poured through a drain hole (the taphole) into a ladle for transport.

Understanding the Operational Trade-offs

Simply following the steps is not enough. Efficient and safe operation requires managing critical variables and potential challenges.

Power vs. Refractory Wear

Aggressive, high-power melting profiles can decrease the time it takes to make a batch of steel, increasing productivity.

However, this intensity also increases wear and tear on the expensive refractory lining, leading to more frequent and costly maintenance.

Scrap Quality vs. Final Product

Using lower-cost, lower-quality scrap can reduce initial material expenses.

This often requires a longer and more intensive refining process to remove unwanted elements, consuming more energy, alloys, and time, which can negate the initial savings.

Speed vs. Safety

Minimizing "tap-to-tap" time is a primary goal for productivity.

However, rushing procedures, such as charging or maintenance, can compromise the rigorous health and safety protocols that are essential for operating such powerful and dangerous equipment.

Making the Right Choice for Your Goal

The operational focus of an EAF can be adjusted depending on the primary objective of the melt shop.

- If your primary focus is maximum productivity: The key is to minimize tap-to-tap time by optimizing scrap charging, using high-power melting profiles, and ensuring rapid furnace turnaround.

- If your primary focus is producing high-quality steel: The key is careful scrap selection and precise control over the refining stage to meet exact chemical specifications.

- If your primary focus is cost control and longevity: The key is balancing electrical energy consumption with refractory wear and performing diligent preventative maintenance.

Ultimately, successful EAF operation is a masterful balance of speed, chemistry, energy management, and safety.

Summary Table:

| EAF Operation Phase | Key Action | Primary Goal |

|---|---|---|

| Furnace Charging | Load scrap metal into the furnace vessel. | Prepare raw materials for melting. |

| Meltdown | Lower electrodes and strike an electric arc. | Melt the scrap charge into liquid steel. |

| Refining | Add alloys/fluxes and sample chemistry. | Achieve the target steel specification. |

| Tapping | Tilt furnace to pour molten steel into a ladle. | Transfer finished product for casting. |

Optimize Your Steel Production with KINTEK

Operating an electric arc furnace efficiently requires a delicate balance of speed, quality, and cost control. Whether your goal is maximizing productivity, achieving superior steel quality, or extending equipment longevity, having the right lab equipment for precise chemical analysis and process monitoring is critical.

KINTEK specializes in providing high-quality laboratory equipment and consumables tailored to the demanding needs of the metals industry. From robust refractories to precise sampling tools, our products help you manage the key trade-offs of EAF operation—ensuring safety, reducing downtime, and improving your bottom line.

Ready to enhance your melt shop's performance? Contact our experts today to discuss how KINTEK's solutions can support your specific operational goals.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process