In essence, the primary advantages of ceramic materials are rooted in their exceptional resilience. They exhibit high resistance to heat, abrasion, corrosion, and electricity, all stemming from a unique atomic structure that also provides remarkable hardness and strength.

The defining advantage of ceramics comes from their strong ionic and covalent bonds. This atomic-level stability is what grants them their signature hardness and resilience against the chemical, thermal, and electrical challenges that cause metals and polymers to fail.

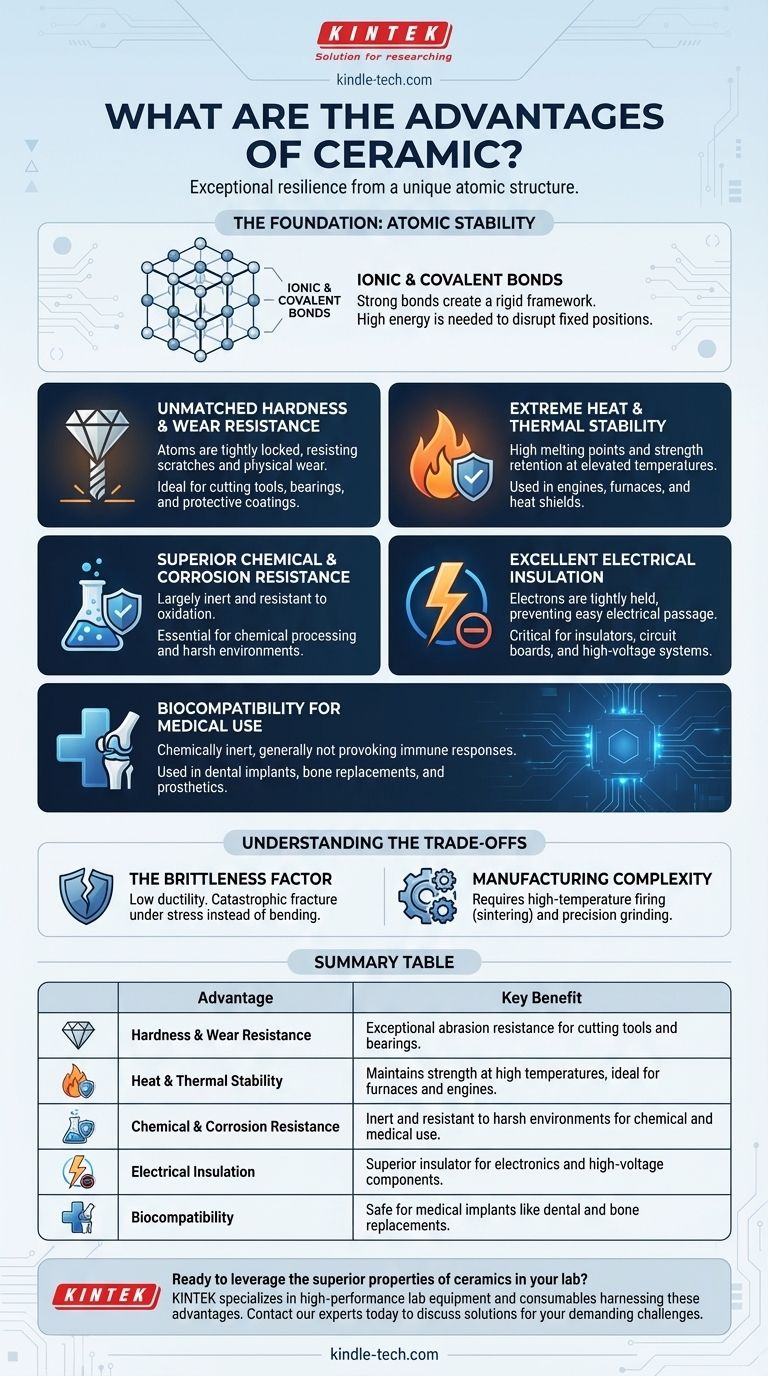

The Foundation: Why Ceramics Are So Robust

To understand the advantages of ceramics, we must first look at their fundamental structure. Unlike metals, which have a "sea" of free-moving electrons, the atoms in a ceramic are locked into a rigid framework.

A Matter of Atomic Bonds

The atoms in advanced ceramics are held together by ionic or covalent bonds. These are two of the strongest types of chemical bonds in nature.

This powerful bonding means that a significant amount of energy is required to disrupt the atoms from their fixed positions, which is the root cause of nearly all of their beneficial properties.

Key Advantages in Application

This unique atomic structure translates directly into tangible performance benefits across a wide range of demanding applications.

Unmatched Hardness and Wear Resistance

Because the atoms are so tightly locked in place, it is extremely difficult to scratch or physically wear down a ceramic surface. This results in high hardness and exceptional abrasion resistance.

This property makes ceramics ideal for applications like cutting tools, industrial bearings, and protective coatings where friction and wear are primary concerns.

Extreme Heat and Thermal Stability

The strong bonds require immense energy to vibrate and break apart. Consequently, ceramics have very high melting points and maintain their strength at elevated temperatures.

This is why they are used in engine components, furnace linings, and as heat shields on spacecraft, performing reliably in environments that would melt most metals.

Superior Chemical and Corrosion Resistance

Ceramic materials are largely inert. Many are already in a stable, oxidized state, meaning they do not readily react with oxygen or other corrosive substances.

This resistance to corrosion and oxidation makes them essential for chemical processing equipment, medical implants, and any application exposed to harsh chemical environments.

Excellent Electrical Insulation

The same strong bonds that hold the atoms in place also hold their electrons tightly. With no free-flowing electrons, electricity cannot pass through the material easily.

This makes ceramics superb electrical insulators, which is why they are critical for spark plugs, circuit boards, and high-voltage power line components.

Biocompatibility for Medical Use

The chemical inertness of ceramics means they generally do not provoke an immune response from the human body.

This biocompatibility allows for their safe use in a wide range of medical applications, including dental implants, bone replacements, and prosthetic joints.

Understanding the Trade-offs

No material is perfect. To use ceramics effectively, it is critical to understand their primary limitation.

The Brittleness Factor

The same rigid atomic structure that provides hardness also means ceramics have low ductility. When a metal is struck, its atoms can slip past one another, allowing it to bend or deform.

In a ceramic, there is no mechanism for this kind of movement. When the stress exceeds the material's limit, the bonds fracture catastrophically instead of bending. This property is known as brittleness.

Manufacturing Complexity

Processing ceramics into finished parts often requires high-temperature firing processes (sintering) and precision grinding, which can be more complex and costly than manufacturing with metals or polymers.

Making the Right Choice for Your Goal

Selecting a ceramic is a decision to prioritize performance under extreme conditions over ductility and ease of manufacturing.

- If your primary focus is performance in extreme environments: Ceramics are the ideal choice for applications involving high heat, abrasive wear, or corrosive chemicals.

- If your primary focus is electrical isolation: The inherent insulating properties of ceramics make them essential for electronic components and high-voltage systems.

- If your primary focus is biocompatibility and inertness: Ceramics are unparalleled for medical implants and components that must not react with their surroundings.

- If your primary focus is impact resistance: You must carefully consider the trade-off of brittleness and may need to engineer the system to avoid shock loading or explore toughened composite ceramics.

By understanding their fundamental properties, you can leverage the distinct advantages of ceramics to solve engineering challenges that other materials simply cannot withstand.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Hardness & Wear Resistance | Exceptional abrasion resistance for cutting tools and bearings. |

| Heat & Thermal Stability | Maintains strength at high temperatures, ideal for furnaces and engines. |

| Chemical & Corrosion Resistance | Inert and resistant to harsh environments for chemical and medical use. |

| Electrical Insulation | Superior insulator for electronics and high-voltage components. |

| Biocompatibility | Safe for medical implants like dental and bone replacements. |

Ready to leverage the superior properties of ceramics in your lab?

KINTEK specializes in high-performance lab equipment and consumables that harness the advantages of ceramic materials for extreme conditions. Whether you need components with exceptional thermal stability, wear resistance, or chemical inertness, our solutions are designed to enhance the reliability and efficiency of your laboratory processes.

Contact our experts today to discuss how our ceramic-based products can solve your most demanding challenges.

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

People Also Ask

- What is the temperature for ceramic parts sintering? A Guide to Material-Specific Sintering Cycles

- What ceramics are used for insulation? Choose the Right Material for Thermal or Electrical Needs

- What is the function of high-purity alumina powder in pack cementation? Ensure Uniform Aerospace Blade Coatings

- What are the properties of SiC? Unlock High-Temperature, High-Frequency Performance

- What is the purpose of using ceramic fiber insulation in molten salt pipelines? Ensure Fluidity and Energy Efficiency

- What are the properties of silicon carbide tubing? Master Extreme Conditions with Unmatched Durability

- What are some of the important characteristics of sintered ceramics? Achieve High-Performance Material Properties

- How does Alumina (Al2O3) ceramic coating influence CdS tribocatalytic activity? Boost Degradation Rates by 6X