The primary advantage of Graphite Furnace Atomic Absorption Spectroscopy (GFAAS) over Flame AAS is its vastly superior sensitivity. This allows analysts to detect concentrations of an element that are 100 to 1,000 times lower than what is possible with a flame. Furthermore, GFAAS achieves this sensitivity using a much smaller sample volume, making it ideal for precious or limited materials.

GFAAS offers exceptional sensitivity for trace and ultra-trace analysis, allowing you to measure parts-per-billion levels with minimal sample. However, this precision comes at the cost of lower throughput and a more complex process compared to the robust and rapid Flame AAS method.

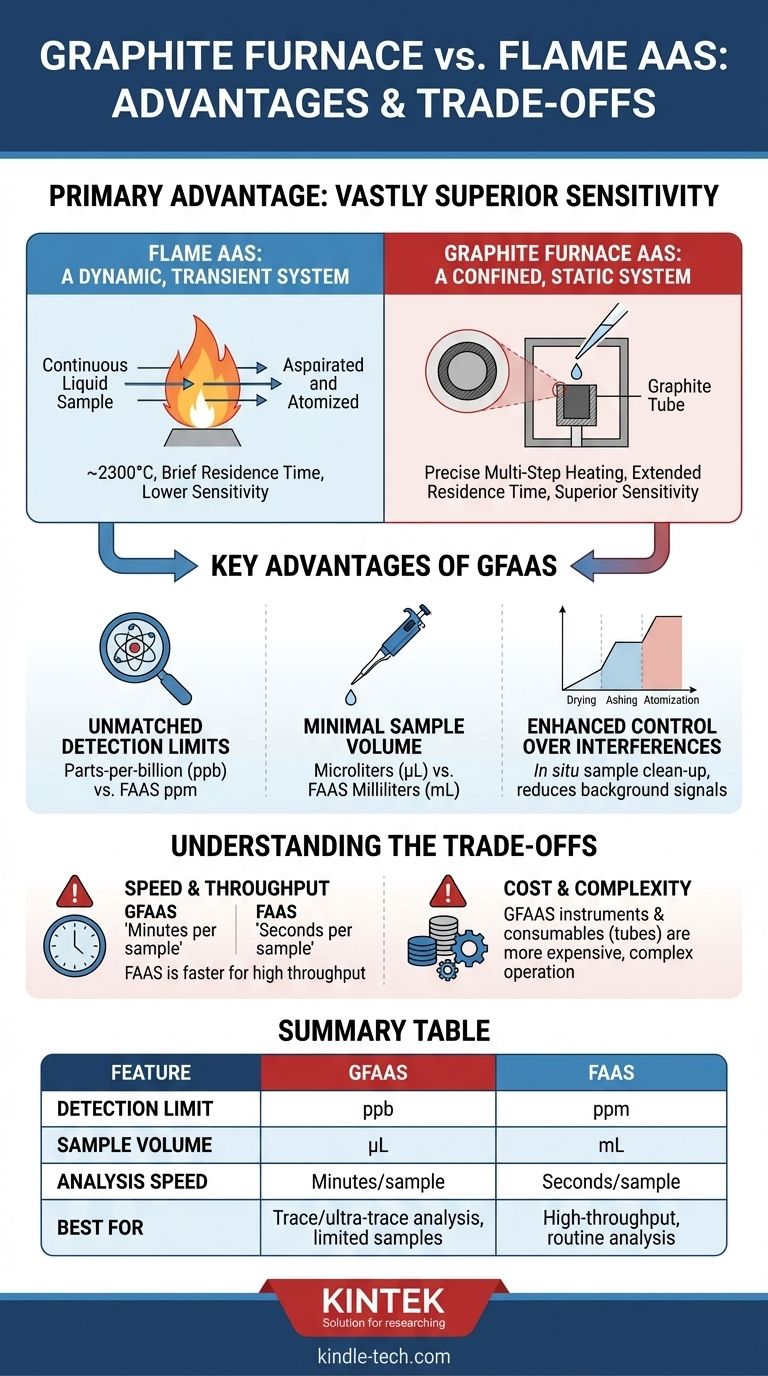

The Fundamental Difference: Atomization Environment

The advantages of the graphite furnace stem directly from how it converts a sample into free atoms for measurement. This process is known as atomization.

Flame AAS: A Dynamic, Transient System

In Flame Atomic Absorption Spectroscopy (FAAS), the liquid sample is continuously aspirated into a flame. The flame's high temperature (e.g., ~2300°C for air-acetylene) desolvates the sample and converts the analyte into free atoms.

These atoms then pass through the instrument's light path, but only for a fraction of a second. This brief residence time limits the sensitivity of the measurement.

Graphite Furnace AAS: A Confined, Static System

In GFAAS, a small, discrete volume of sample (typically 5-50 microliters) is pipetted directly into a graphite tube. This tube is then heated in a precisely controlled, multi-step program inside a confined, inert argon atmosphere.

This method traps the entire population of atomized analyte in the light path for a much longer period—several seconds. This vastly increased residence time is the principal reason for the technique's superior sensitivity.

Key Advantages of the Graphite Furnace Method

The unique atomization environment of the graphite furnace provides three distinct, powerful advantages over a flame.

Unmatched Detection Limits

The longer residence time of the atom cloud directly translates to a much stronger absorption signal for a given concentration. This allows GFAAS to routinely achieve detection limits in the parts-per-billion (ppb) range, whereas FAAS is typically limited to the parts-per-million (ppm) range.

Minimal Sample Volume

FAAS requires a continuous flow of sample to maintain a stable flame and signal, often consuming several milliliters (mL) per analysis. GFAAS is a discrete technique that uses only microliters (µL) of sample.

This makes GFAAS the essential choice when analyzing precious biological fluids, expensive reagents, or any sample that is limited in quantity.

Enhanced Control Over Interferences

The GFAAS heating program consists of several distinct stages:

- Drying: Gently removes the solvent at a low temperature.

- Ashing (Pyrolysis): Ramps to a higher temperature to thermally break down and remove the bulk of the sample matrix (e.g., salts, organic matter) before the final measurement.

- Atomization: Rapidly heats to a very high temperature to vaporize the target analyte.

This programmable ashing step is a powerful tool. It allows the analyst to clean up the sample in situ, removing interfering components that would otherwise cause background signal errors in FAAS.

Understanding the Trade-offs

Despite its advantages, GFAAS is not a universal replacement for FAAS. The choice of technique involves significant trade-offs that every analyst must consider.

Speed and Sample Throughput

A single GFAAS analysis takes several minutes to complete due to the programmed heating cycle. In contrast, once an FAAS instrument is calibrated, it can analyze samples in a matter of seconds.

For labs requiring high throughput, such as in routine quality control, the speed of FAAS is a decisive advantage.

Cost and Complexity

GFAAS instruments are generally more expensive to purchase and operate. The graphite tubes are consumable items with a finite lifetime of a few hundred firings, representing a significant ongoing operational cost.

The method is also more complex and less forgiving than FAAS, requiring a more highly skilled operator to develop methods and troubleshoot issues.

Precision and Concentration Range

For concentrations well within the working range of FAAS (ppm levels), the flame technique typically offers better precision (lower relative standard deviation). GFAAS is optimized for trace analysis and can be less precise for higher concentration samples.

Choosing the Right Technique for Your Analysis

Selecting the correct AAS method depends entirely on the goals of your analysis and the nature of your sample.

- If your primary focus is trace or ultra-trace analysis (ppb levels): GFAAS is the necessary and superior choice due to its exceptional sensitivity.

- If you are analyzing mid-to-high concentration samples (ppm levels): Flame AAS is faster, more precise, and more cost-effective.

- If you have very limited sample volume: GFAAS is your only viable option, as it requires only microliters of sample.

- If you need high sample throughput for routine quality control: Flame AAS is the industry standard for its unmatched speed and robustness.

By understanding the fundamental trade-off between sensitivity and speed, you can confidently select the atomic absorption technique that best aligns with your analytical goals.

Summary Table:

| Feature | Graphite Furnace AAS (GFAAS) | Flame AAS (FAAS) |

|---|---|---|

| Detection Limit | Parts-per-billion (ppb) | Parts-per-million (ppm) |

| Sample Volume | Microliters (µL) | Milliliters (mL) |

| Analysis Speed | Minutes per sample | Seconds per sample |

| Best For | Trace/ultra-trace analysis, limited samples | High-throughput, routine analysis |

Ready to enhance your lab's trace analysis capabilities?

KINTEK specializes in providing high-performance lab equipment and consumables, including Graphite Furnace Atomic Absorption Spectroscopy systems. Whether you're working with precious biological samples or need to detect ultra-trace elements, our solutions deliver the sensitivity and precision your research demands.

Contact our experts today to discuss how GFAAS can transform your analytical workflow and help you achieve breakthrough results in your laboratory.

Visual Guide

Related Products

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the mechanical properties of graphite? Harnessing Rigidity and Managing Brittleness

- At what temperature does graphite melt? Understanding Its Extreme Phase Change

- Why graphite has high thermal conductivity? Unlock Superior Heat Management with Its Unique Structure

- Why graphite Cannot conduct electricity? Unlocking the Secret of its High Electrical Conductivity

- Why is graphite melting point high? Unlocking the Power of Strong Covalent Bonds