At its core, induction heating offers four primary advantages: it is exceptionally fast, remarkably precise, inherently clean, and highly energy-efficient. Unlike traditional methods that heat a material's surface from the outside, induction heating generates heat directly inside the workpiece itself using a powerful, non-contact magnetic field.

The fundamental benefit of induction heating stems from a single principle: contactless, internal heat generation. This unique mechanism is the source of its superior speed, control, and cleanliness compared to conventional flame or resistance heating methods.

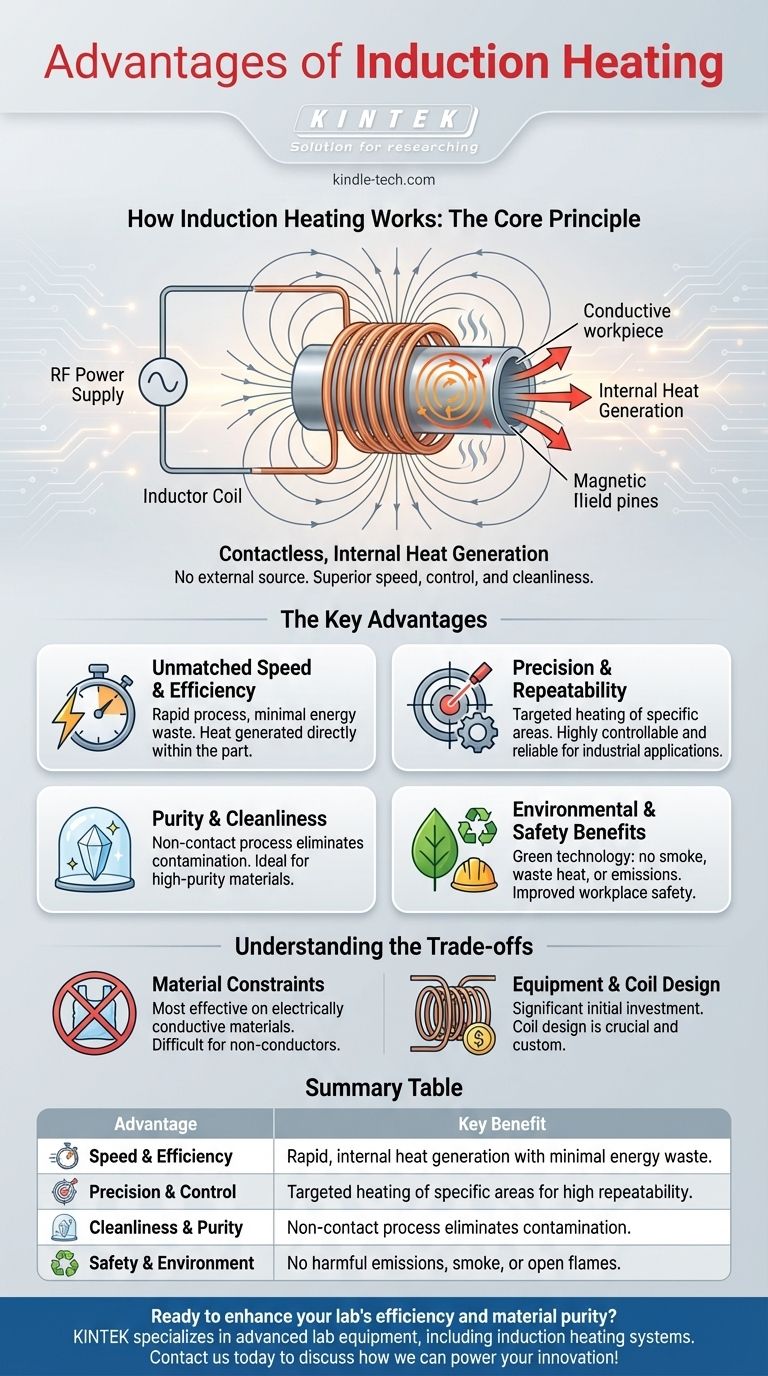

How Induction Heating Works: The Core Principle

To understand the advantages, we must first understand the mechanism. The process is a direct application of electromagnetic principles.

The System Components

An induction heating system consists of three main parts: an RF power supply that generates an alternating current, an inductor (typically a copper coil), and the workpiece to be heated.

The Electromagnetic Process

An alternating current flows through the copper coil, creating a rapidly alternating magnetic field around it. When a conductive workpiece is placed within this field, the field induces electrical currents, known as eddy currents, to flow within the material.

The Source of the Heat

The resistance of the material to the flow of these eddy currents generates precise and localized heat. Because this process happens inside the material itself, no external heat source or physical contact is required.

The Key Advantages Explained

The unique physics of induction heating directly translates into significant operational benefits across various industries, from metallurgy to semiconductor manufacturing.

Unmatched Speed and Efficiency

Because heat is generated directly within the part, the process is incredibly rapid. There is no need to wait for heat to conduct from an external source. This also means very little energy is wasted heating the surrounding atmosphere, making the process highly energy-efficient.

Precision and Repeatability

The magnetic field can be precisely controlled and shaped by the design of the inductor coil. This allows for the targeted heating of very specific areas of a part, leaving other sections unaffected. This level of control makes the process highly repeatable and reliable for industrial applications.

Purity and Cleanliness

Induction heating is a non-contact process. The workpiece never touches a flame or a heating element, which completely eliminates contamination that can occur with other methods. This is critical in applications like Czochralski crystal growth or melting high-purity metals.

Environmental and Safety Benefits

Considered a green technology, induction heating produces no smoke, waste heat, or harmful emissions. By eliminating the need for an open flame or red-hot elements, it significantly improves workplace safety.

Understanding the Trade-offs

While powerful, induction heating is not a universal solution. Its effectiveness is governed by the principles on which it operates.

Material Constraints

The primary limitation is that induction heating is most effective on electrically conductive materials. The process relies on inducing eddy currents, which is difficult to achieve in non-conductors like plastics or ceramics without special considerations.

Equipment and Coil Design

The initial investment in a solid-state RF power supply can be significant. Furthermore, the efficiency and precision of the heating process are heavily dependent on the design of the inductor coil, which often must be customized for the specific geometry of the workpiece.

Making the Right Choice for Your Application

Selecting the right heating method depends entirely on your primary goal.

- If your primary focus is high-volume, repeatable manufacturing: The speed and precise control of induction heating deliver unparalleled consistency and throughput.

- If your primary focus is high-purity material processing: The non-contact, contaminant-free nature of the process is essential for applications in metallurgy and semiconductors.

- If your primary focus is improving energy efficiency and workplace safety: Induction heating provides a clean, emission-free alternative to fossil fuel-based heating methods.

Ultimately, induction heating empowers you to place heat exactly where you need it, exactly when you need it, with no waste.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Speed & Efficiency | Rapid, internal heat generation with minimal energy waste. |

| Precision & Control | Targeted heating of specific areas for high repeatability. |

| Cleanliness & Purity | Non-contact process eliminates contamination. |

| Safety & Environment | No harmful emissions, smoke, or open flames. |

Ready to enhance your lab's efficiency and material purity with induction heating? KINTEK specializes in advanced lab equipment, including induction heating systems, to meet the precise needs of laboratories in metallurgy, semiconductor manufacturing, and high-purity processing. Our solutions deliver the speed, control, and cleanliness your research demands. Contact us today to discuss how we can power your innovation!

Visual Guide

Related Products

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Double Plate Heating Press Mold for Lab

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- What is the proper post-treatment procedure for a platinum sheet electrode? Ensure Long-Term Accuracy & Protect Your Investment

- What are the available specifications for platinum sheet electrodes? Find the Perfect Fit for Your Electrochemical Needs

- What are the performance characteristics of platinum sheet electrodes? Unlock Superior Electrochemical Performance

- What is the most critical guideline for immersing a platinum sheet electrode in an electrolyte? Ensure Accurate Electrochemical Measurements

- What are the key performance characteristics and applications of platinum sheets? Unmatched Reliability for Demanding Applications