In short, compressors are used in nearly every industry to provide power for tools, transport gases, enable chemical reactions, and create cooling. Their applications range from inflating your car tires and powering air conditioners to operating complex machinery in manufacturing plants and oil refineries.

A compressor is best understood not just as a device that squeezes air, but as a fundamental tool for converting electrical or mechanical energy into the potential energy of a pressurized gas, making that energy portable, powerful, and useful for a vast range of tasks.

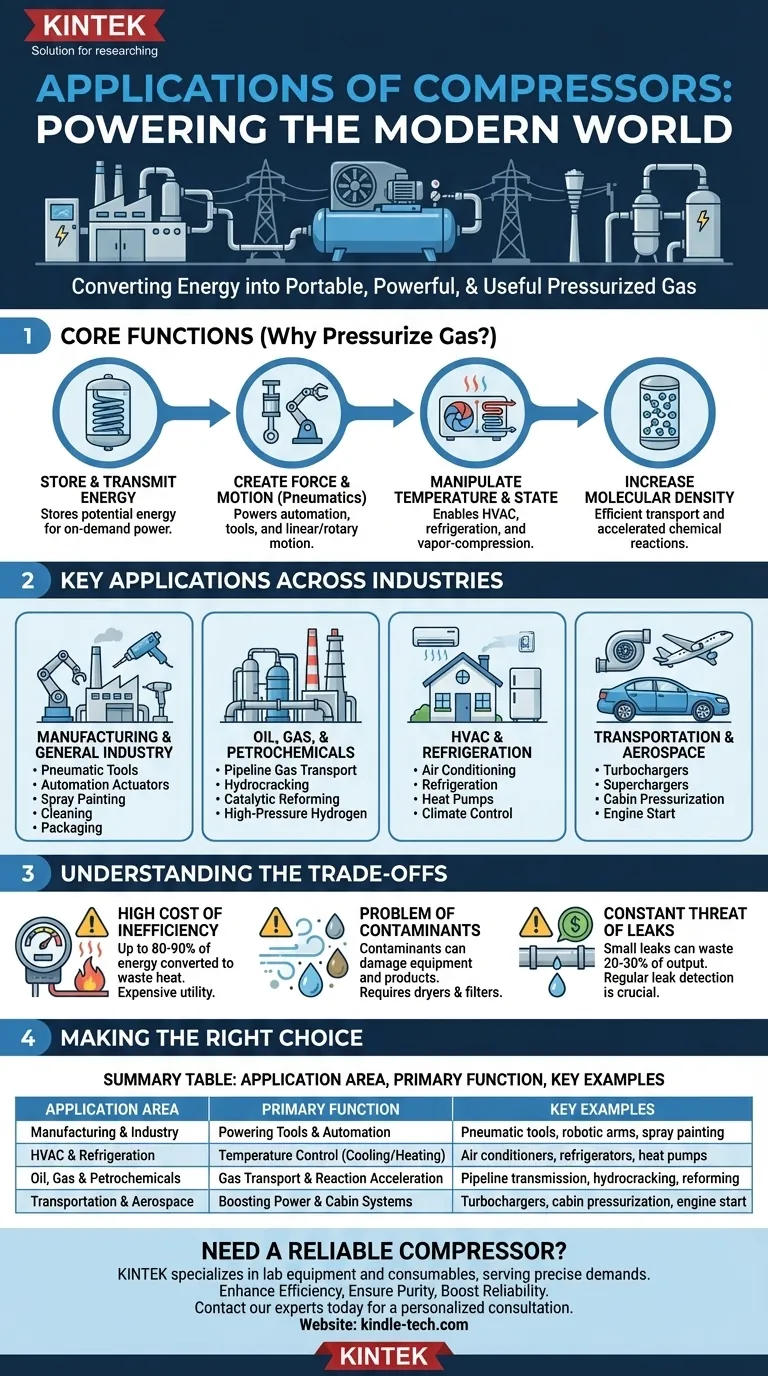

The Core Function: Why Compress a Gas?

To understand the countless applications of compressors, you must first grasp the four fundamental reasons why we pressurize a gas in the first place. Every application is a variation on one of these core principles.

To Store and Transmit Energy

Compressing a gas is like coiling a spring; it stores potential energy. This energy can be held in a receiver tank and used on-demand, often far from the compressor itself.

This stored energy can then be released to perform work, making compressed air a clean and robust energy transmission system.

To Create Force and Motion (Pneumatics)

Pressurized gas can be directed to push a piston or turn a vane, creating controlled linear or rotary motion. This is the principle behind pneumatics.

Pneumatic systems power everything from factory automation and robotic arms to handheld tools like nail guns, impact wrenches, and sanders. They are valued for their durability, simplicity, and safety in hazardous environments.

To Manipulate Temperature and State

The laws of physics dictate that when a gas is compressed, its temperature increases, and when it expands, its temperature decreases. This is the foundation of the vapor-compression cycle.

Compressors are the heart of all modern refrigeration, air conditioning (HVAC), and heat pump systems. They pressurize a refrigerant, forcing it to release heat outside, before allowing it to expand and absorb heat from the space you want to cool.

To Increase Molecular Density

Forcing gas molecules closer together increases their density. This is critical for two main reasons: transportation and chemical reactions.

Higher density allows more gas to be stored in a given volume (like a SCUBA tank) or transported efficiently through a pipeline. It also dramatically accelerates chemical reaction rates, which is essential in the chemical and petrochemical industries.

Key Applications Across Industries

With the core principles understood, the specific applications of compressors become clear extensions of these functions.

Manufacturing and General Industry

This is the most common environment for compressors. They act as a "fourth utility" alongside electricity, natural gas, and water.

Uses include powering pneumatic tools, operating actuators on automated assembly lines, and providing air for spray painting, cleaning, and packaging equipment.

Oil, Gas, and Petrochemicals

Compressors are indispensable in the energy sector. They are used to move natural gas through thousands of miles of pipelines.

In refineries, compressors provide high-pressure hydrogen and other gases needed for critical processes like hydrocracking and catalytic reforming, which break down crude oil into gasoline and other valuable products.

HVAC and Refrigeration

Every refrigerator, freezer, and air conditioner in homes, cars, and commercial buildings relies on a compressor to pump refrigerant and move heat. This is arguably the most common consumer-facing application.

Transportation and Aerospace

Internal combustion engines use turbochargers or superchargers—both of which are specialized compressors—to force more air into the cylinders, boosting engine power and efficiency.

Aircraft use compressors for cabin pressurization and to provide the high-volume "bleed air" needed to start their massive jet engines.

Understanding the Trade-offs

While incredibly useful, compressed air is not a "free" resource. Understanding its limitations is critical for efficient and safe operation.

The High Cost of Inefficiency

The process of compressing air is inherently inefficient. A large portion of the electrical energy consumed by a compressor, often as much as 80-90%, is converted directly into waste heat.

This makes compressed air one of the most expensive utilities in a facility. Managing this waste heat and the overall energy consumption is a major operational concern.

The Problem of Contaminants

Atmospheric air is not pure. It contains water vapor, dust particles, and often oil aerosols from the compressor itself.

These contaminants must be removed using dryers and filters. Failure to do so can damage pneumatic equipment, contaminate end products (like food or pharmaceuticals), and cause operational failures.

The Constant Threat of Leaks

A small, unheard leak in a compressed air line is a constant and direct drain of energy and money. A system of small leaks can easily waste 20-30% of a compressor's total output.

Detecting and repairing leaks is a crucial and ongoing maintenance task required to operate any compressed air system efficiently.

Making the Right Choice for Your Goal

Your perspective on a compressor depends entirely on the problem you are trying to solve.

- If your primary focus is industrial efficiency: View compressed air as one of your most expensive utilities and prioritize leak management, proper sizing, and heat recovery to control costs.

- If your primary focus is process engineering: See the compressor as a tool to manipulate pressure, density, and temperature to enable or accelerate chemical reactions and phase changes.

- If your primary focus is mechanical automation: Recognize pneumatic systems powered by compressors as a robust, clean, and powerful method for creating motion, especially in demanding industrial environments.

Ultimately, a compressor is a powerful energy converter, transforming raw power into a flexible and widely applicable utility that drives the modern world.

Summary Table:

| Application Area | Primary Function | Key Examples |

|---|---|---|

| Manufacturing & Industry | Powering Tools & Automation | Pneumatic tools, robotic arms, spray painting |

| HVAC & Refrigeration | Temperature Control (Cooling/Heating) | Air conditioners, refrigerators, heat pumps |

| Oil, Gas & Petrochemicals | Gas Transport & Reaction Acceleration | Pipeline transmission, hydrocracking, reforming |

| Transportation & Aerospace | Boosting Power & Cabin Systems | Turbochargers, cabin pressurization, engine start |

Need a Reliable Compressor for Your Laboratory or Industrial Process?

Compressors are the workhorses of modern industry, and choosing the right one is critical for efficiency, safety, and performance. Whether your lab requires clean, oil-free air for sensitive instruments or your manufacturing process depends on robust pneumatic power, KINTEK has the expertise and equipment to meet your needs.

KINTEK specializes in lab equipment and consumables, serving the precise demands of laboratories and industrial facilities. We can help you select the ideal compressor solution to:

- Enhance Efficiency: Minimize energy waste and operational costs.

- Ensure Purity: Meet strict contamination standards for sensitive applications.

- Boost Reliability: Power your tools and processes with dependable performance.

Let's discuss your specific requirements. Contact our experts today for a personalized consultation and discover how KINTEK can power your success.

Visual Guide

Related Products

- Infrared Heating Quantitative Flat Plate Press Mold

- Automatic Laboratory Heat Press Machine

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Ball Press Mold for Lab

People Also Ask

- What is the standard temperature for heat press? Master the Perfect Settings for Durable Transfers

- What role do molds play in the formation of Ruthenium sheets? Master High-Density Ruthenium Fabrication

- What's the difference between a heat press machine and an iron? Achieve Professional, Durable Apparel Transfers

- Is a heat press machine good for t-shirts? Unlock Professional, Custom Apparel Creation

- What is a good mini heat press? Achieve Professional Results on Small, Complex Items