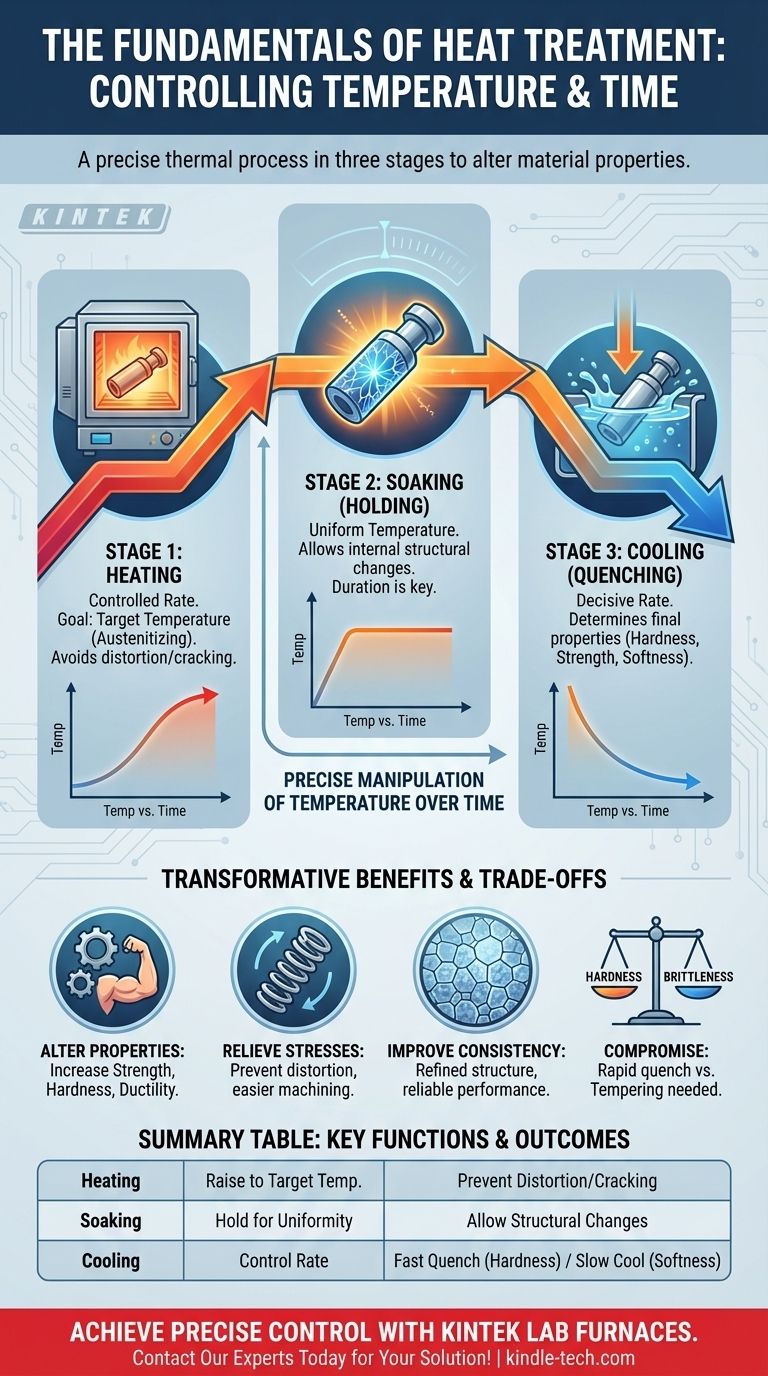

At its core, heat treatment consists of three fundamental stages: heating, soaking, and cooling. This controlled thermal process is not defined by the physical parts of a furnace, but by the precise manipulation of temperature over time to intentionally alter a material's internal structure and, consequently, its physical and mechanical properties.

The success of any heat treatment is determined by the precise control over its three core components: the rate of heating, the duration of soaking at a target temperature, and, most critically, the rate of cooling.

The Three Foundational Stages of Heat Treatment

To understand how heat treatment achieves its results, you must first understand the purpose of each distinct stage in the process. It is a carefully orchestrated sequence where every step builds upon the last.

Stage 1: The Heating Cycle

The first step is to heat the material in a controlled manner. The goal is to bring the entire part to a specific target temperature, known as the austenitizing temperature for most steels.

The rate of heating is a critical variable. Heating a component too quickly can cause internal stresses due to thermal expansion, leading to distortion or even cracking, especially in complex shapes.

Stage 2: The Soaking (or Holding) Period

Once the material reaches the target temperature, it is held there for a specific amount of time. This is the soaking or holding stage.

The purpose of soaking is to ensure the entire volume of the material, from the surface to the core, has reached a uniform temperature. It also provides the necessary time for the desired changes in the material's internal crystalline structure (microstructure) to occur.

Stage 3: The Cooling (or Quenching) Cycle

The final and often most decisive stage is cooling. The rate at which the material is cooled from the target temperature directly dictates its final hardness, strength, and other mechanical properties.

Different cooling rates are achieved using various methods, from a rapid quench in water or oil for maximum hardness to a very slow cool inside an insulated furnace for maximum softness.

Why These Stages Matter: The Goal of Heat Treatment

The precise execution of these three stages allows engineers to achieve specific, desirable outcomes in a material. The benefits are transformative for manufacturing and engineering applications.

Altering Mechanical Properties

The primary goal is often to change a material's physical characteristics. This includes increasing its strength, creating extreme surface hardness for wear resistance, or improving its ductility and toughness to resist fracture.

Relieving Internal Stresses

Processes like manufacturing, welding, or hot forming can lock internal stresses into a part. A controlled heat treatment cycle, particularly one with slow cooling (annealing), can relieve these stresses, making the part easier to machine and preventing future distortion.

Improving Material Consistency

Heat treatment refines the grain structure of the metal. This homogenization improves overall consistency, ensuring the material will perform reliably and predictably under load.

Understanding the Trade-offs

Heat treatment is a science of compromise. Improving one property often comes at the expense of another, and improper control can introduce new problems.

The Hardness vs. Brittleness Compromise

A fundamental trade-off exists between hardness and toughness. A very rapid quench can make steel extremely hard, but it also makes it very brittle and susceptible to cracking. A secondary, lower-temperature treatment called tempering is often required to restore some toughness.

The Risk of Distortion and Cracking

As mentioned, improper control over heating and cooling rates is the primary cause of failure. The thermal gradients created can cause a part to warp, distort, or crack, rendering it useless. This is why control is paramount.

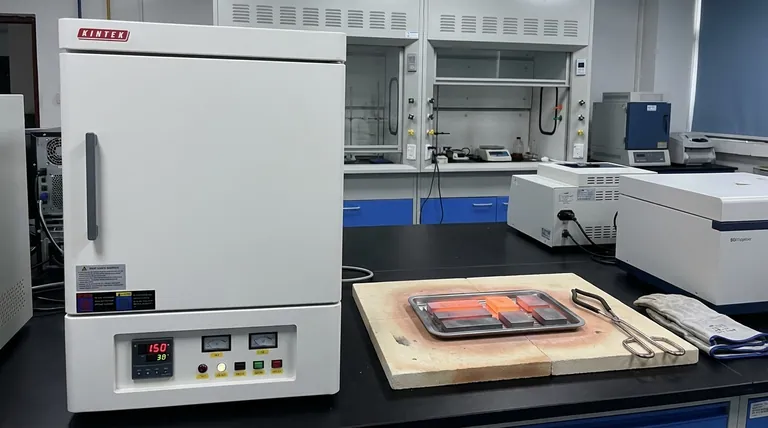

The Role of Equipment

Achieving precise thermal control requires specialized equipment. The choice of furnace and its heating elements—such as resistance wires for lower temperatures or silicon molybdenum rods for higher temperatures—is dictated by the specific temperature profile required for the treatment cycle.

Matching the Process to Your Material Goal

The specific parameters of the three stages are adjusted based on the material and the desired outcome.

- If your primary focus is maximum hardness (hardening): You will use a rapid cooling cycle, or quench, after a thorough soak.

- If your primary focus is maximum softness and stress relief (annealing): You will use a very slow, controlled cooling cycle inside the furnace.

- If your primary focus is balancing hardness and toughness (tempering): You will perform a secondary, lower-temperature heat treatment after the initial hardening quench.

Ultimately, mastering heat treatment is about understanding that you are commanding a fundamental change in a material's very structure through the disciplined application of temperature and time.

Summary Table:

| Stage | Key Function | Outcome/Consideration |

|---|---|---|

| Heating | Raise material to target temperature. | Must be controlled to prevent distortion/cracking. |

| Soaking | Hold at temperature for uniformity. | Allows internal structural changes to occur. |

| Cooling | Control rate to set final properties. | Fast quench for hardness; slow cool for softness. |

Achieve precise control over your heat treatment processes with KINTEK.

Whether you need to harden, anneal, or temper, the right lab furnace is critical for executing the heating, soaking, and cooling stages with accuracy. KINTEK specializes in providing reliable lab equipment and consumables tailored to your laboratory's specific thermal processing needs.

Let us help you enhance your material properties and improve consistency. Contact our experts today to find the perfect solution for your application!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- How does a muffle oven work? Achieve Pure, Contamination-Free Heating for Your Lab

- What is the difference between a muffle furnace and a drying oven? Choose the Right Thermal Tool

- What is a muffle furnace and its uses? Achieve Contamination-Free High-Temperature Processing

- What is the use of muffle furnace in chemistry laboratory? Achieve Precise High-Temperature Material Processing

- What is the difference between an oven and a muffle? Choose the Right Heating Tool for Your Lab