The primary benefits of hot isostatic pressing (HIP) are the complete removal of internal porosity and the significant enhancement of a material's mechanical properties. By applying high temperature and uniform gas pressure, the process consolidates materials into a fully dense state, which dramatically increases ductility, fatigue resistance, and overall component integrity without altering the part's shape.

The core problem with many manufacturing methods, like casting or 3D printing, is the presence of microscopic internal voids that act as failure points. Hot Isostatic Pressing is the definitive solution, using immense, uniform pressure to physically collapse and eliminate these flaws, thereby unlocking the material's maximum theoretical performance.

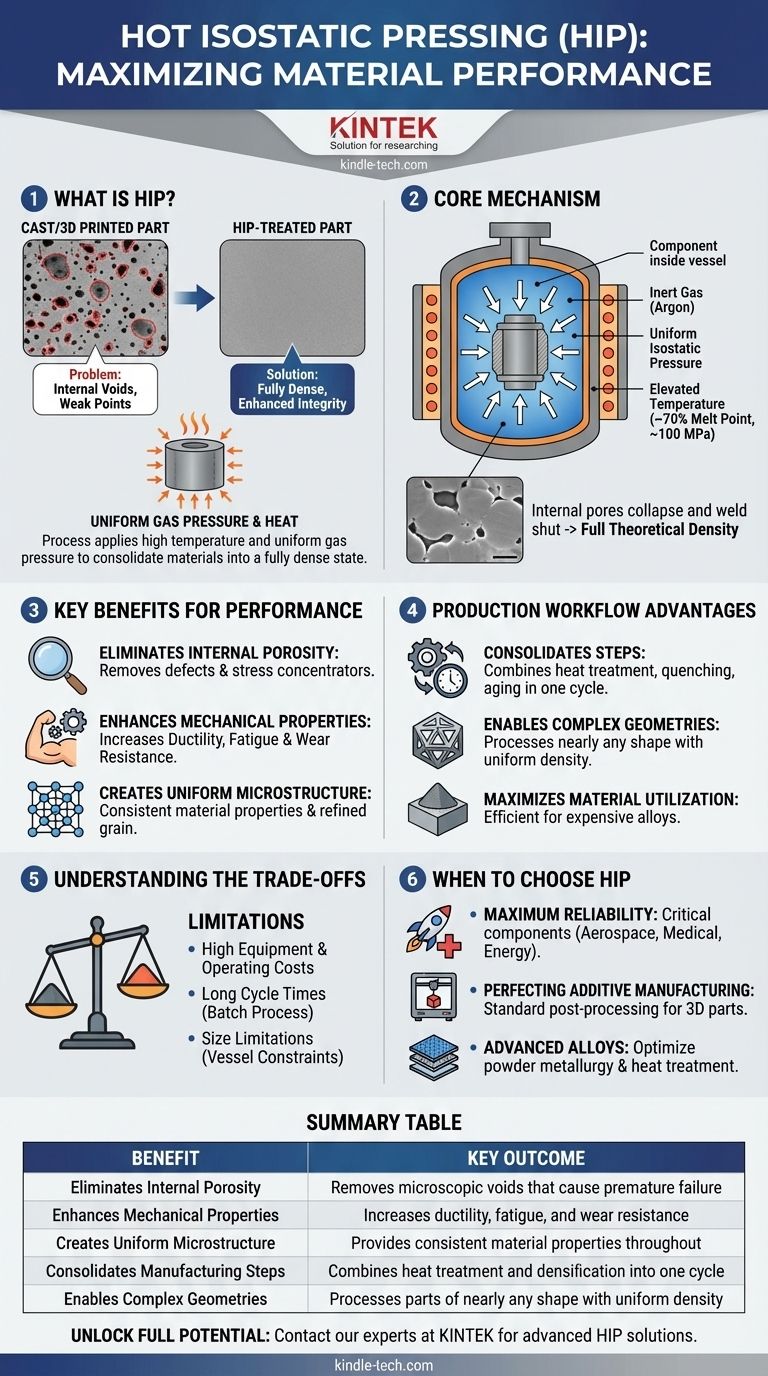

The Core Mechanism: How HIP Transforms Materials

Hot Isostatic Pressing is a manufacturing process that subjects a component to both elevated temperature and high-pressure gas. This combination is the key to its transformative effects on a material's internal structure.

Applying Uniform Pressure and Heat

The component is placed inside a vessel, which is then heated and filled with an inert gas, typically argon. This gas is pressurized to exert an equal force on all surfaces of the part.

This isostatic pressure is critical. Unlike unidirectional pressing in a die, it compacts the material uniformly, ensuring that density is consistent throughout the entire component and preventing shape distortion.

The Goal: Achieving Full Theoretical Density

The process typically operates at temperatures around 70% of the material's melting point and pressures of approximately 100 MPa (15,000 psi).

This forces the material to plastically deform on a microscopic level, causing any internal voids or pores to collapse and weld shut. The result is a fully dense part with properties that are equivalent to, or even better than, those of a traditionally wrought material.

Key Benefits for Component Performance

By creating a fully dense and uniform microstructure, HIP directly translates into superior, more reliable parts. These benefits are especially critical for components used in demanding environments.

Eliminating Internal Porosity

Porosity is the primary weakness in cast and additively manufactured parts. These tiny internal voids act as stress concentrators where cracks can initiate and propagate, leading to premature failure.

HIP completely removes this porosity, healing defects and creating a solid, homogenous structure.

Enhancing Mechanical Properties

With porosity eliminated, the material's inherent strength is no longer compromised. This leads to dramatic improvements across a range of mechanical properties.

Key enhancements include significantly increased ductility, fatigue resistance, wear resistance, and abrasion resistance. HIP-treated parts can withstand more stress, last longer, and perform more reliably in harsh conditions.

Creating a Uniform Microstructure

The process also helps to create a more consistent and refined grain structure throughout the material.

HIP relieves thermal stresses that may be locked into a part from casting or 3D printing. For additive manufacturing specifically, it improves the adhesion between printed layers, further strengthening the component.

Advantages in the Production Workflow

Beyond improving the final part, Hot Isostatic Pressing can also introduce significant efficiencies into the manufacturing process itself.

Consolidating Manufacturing Steps

For many advanced alloys, HIP can integrate post-processing steps into a single cycle.

Processes like heat treatment, quenching, and aging can often be combined within the HIP cycle. This consolidation reduces the number of required steps, shortening overall production time and lowering costs.

Enabling Complex Geometries

Traditional uniaxial pressing is limited by the geometry of its rigid dies. HIP, however, can process pre-formed parts of nearly any shape.

This allows for the creation of complex components that would be difficult or impossible to compact using other methods, all while achieving high, uniform density.

Maximizing Material Utilization

The HIP process is highly efficient, especially when starting from a powder-based form. It is an ideal method for working with expensive or difficult-to-compact materials, ensuring minimal waste.

Understanding the Trade-offs

While powerful, HIP is a specialized process with specific considerations that make it unsuitable for every application. Understanding its limitations is key to using it effectively.

High Equipment and Operating Costs

The machinery required to safely generate extreme heat and pressure is complex and expensive. The energy consumption during a cycle is also substantial, contributing to a high operating cost per part.

Long Cycle Times

A typical HIP cycle can last for several hours. This makes it a batch process best suited for high-value components rather than high-volume, low-cost mass production.

Size Limitations

The size of the component that can be processed is ultimately constrained by the internal dimensions of the HIP vessel. While very large units exist, they represent a significant capital investment.

When to Choose Hot Isostatic Pressing

The decision to use HIP should be driven by the performance requirements of the final component. It is a tool for achieving the highest levels of material integrity.

- If your primary focus is maximum reliability and performance: Use HIP for critical components in the aerospace, medical, or energy sectors where failure could have catastrophic consequences.

- If your primary focus is perfecting additive manufactured parts: Use HIP as a standard post-processing step to transform 3D-printed metal parts from near-net-shape prototypes into fully dense, production-grade components.

- If your primary focus is working with advanced alloys: Use HIP to achieve full density in powder metallurgy parts and to consolidate heat treatment cycles, optimizing both performance and production efficiency.

Ultimately, Hot Isostatic Pressing is the definitive process for ensuring a material meets its full engineering potential.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Eliminates Internal Porosity | Removes microscopic voids that cause premature failure |

| Enhances Mechanical Properties | Increases ductility, fatigue, and wear resistance |

| Creates Uniform Microstructure | Provides consistent material properties throughout the part |

| Consolidates Manufacturing Steps | Combines heat treatment and densification into one cycle |

| Enables Complex Geometries | Processes parts of nearly any shape with uniform density |

Ready to unlock the full potential of your critical components?

KINTEK specializes in advanced thermal processing solutions, including Hot Isostatic Pressing, to help you achieve maximum material density and performance. Whether you're in aerospace, medical, or additive manufacturing, our expertise in lab equipment and consumables ensures your parts meet the highest standards of reliability.

Contact our experts today to discuss how HIP can transform your manufacturing process and deliver superior component integrity.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard