At its core, induction heating is governed by the interplay between the power supply's characteristics, the inductor's design, and the physical properties of the material being heated. The key factors are the frequency and power of the alternating current, the shape and proximity of the induction coil, and the material's resistivity, magnetic permeability, and physical size.

The effectiveness of induction heating is not about a single factor, but about the precise tuning of a complete system. Your ability to control the outcome depends on understanding how the power source, the induction coil, and the workpiece interact to generate heat exactly where and when you need it.

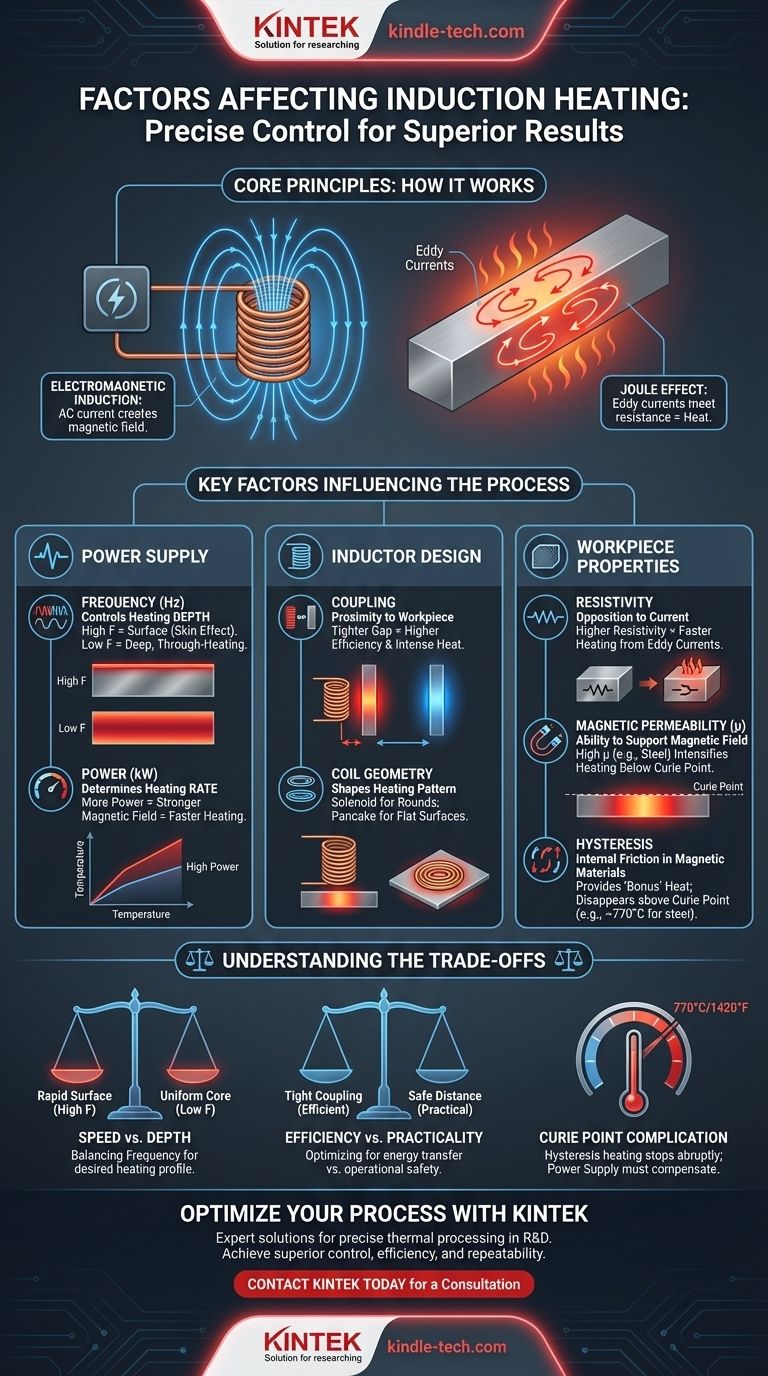

The Core Principles: How Induction Heating Works

To control the process, you must first understand the fundamental physics at play. Induction heating is built on two phenomena working in sequence.

Electromagnetic Induction

An induction system's power supply sends a high-frequency alternating current (AC) through a copper coil, known as the inductor. This AC current generates a powerful, rapidly changing magnetic field around the coil.

When you place an electrically conductive workpiece into this field, the magnetic field induces circulating electrical currents within the part. These are called eddy currents.

The Joule Effect

As these eddy currents swirl through the material, they encounter electrical resistance. This resistance converts the electrical energy of the currents into thermal energy, or heat. This is known as the Joule effect, and it is the primary source of heat in all induction processes.

Key Factors Influencing the Process

Mastering induction heating means understanding and manipulating the variables that affect these core principles. These factors can be grouped into the equipment you control and the properties of the part you're heating.

Power Supply: Frequency and Power

The power supply is your primary control panel. The two most critical settings are frequency and power.

- Frequency determines the depth of heating. Higher frequencies cause the eddy currents to flow in a thin layer near the surface, a phenomenon called the skin effect. Lower frequencies penetrate deeper into the material, allowing for more uniform, through-heating.

- Power (measured in kilowatts) determines the rate of heating. Increasing the power increases the magnitude of the magnetic field, which induces stronger eddy currents and generates heat more quickly.

Inductor Design: The Shape of the Heat

The inductor coil is not just a conductor; it is the tool that shapes the magnetic field and focuses the energy.

- Coupling refers to the proximity of the coil to the workpiece. A smaller gap (tighter coupling) results in a more efficient transfer of energy and more intense heating.

- Coil Geometry dictates the heating pattern. A simple solenoid coil heats the outer diameter of a round bar, while a "pancake" coil can heat a flat surface. The design of the coil is critical for concentrating heat exactly where it is needed.

Workpiece Properties: The Material's Response

The workpiece itself is an active participant in the heating process. Its inherent properties dictate how efficiently it will heat up.

- Resistivity is a measure of a material's opposition to electrical current. Materials with higher resistivity will generate more heat from the same amount of eddy current, heating up faster.

- Magnetic Permeability is the ability of a material to support the formation of a magnetic field. Magnetic materials like iron and steel have high permeability, which greatly intensifies the heating process below a certain temperature (the Curie point).

- Hysteresis Heating is a secondary effect that only occurs in magnetic materials. The rapid reversal of the magnetic field causes internal friction as the material's magnetic domains try to align, generating extra heat. This effect provides a "bonus" heating boost but disappears once the material passes its Curie temperature and becomes non-magnetic.

Understanding the Trade-offs

Optimizing an induction process always involves balancing competing factors. Understanding these trade-offs is key to avoiding common pitfalls.

Speed vs. Depth

Choosing a frequency is the classic trade-off. High frequency provides extremely rapid surface heating, ideal for case hardening. However, it will not effectively heat the core of a thick part. For that, you need a lower frequency and a longer heating time to allow the heat to conduct inward.

Efficiency vs. Practicality

The most energy-efficient setup involves very tight coupling, with the coil positioned as close to the part as possible. However, this can be difficult to achieve in an automated production line and increases the risk of contact between the part and the coil, which could cause a damaging short circuit.

The Curie Point Complication

When heating magnetic steels, remember that the rapid heating from hysteresis will stop abruptly when the material's temperature exceeds the Curie point (around 770°C / 1420°F). Your power supply must be able to compensate for this change to maintain a consistent heating rate.

Making the Right Choice for Your Goal

The optimal setup depends entirely on your specific application. Use your goal to guide your decisions on these key factors.

- If your primary focus is rapid surface hardening: Use a high frequency (100 kHz to 400 kHz) and high power with a precisely shaped inductor coupled closely to the part.

- If your primary focus is through-heating a large billet for forging: Use a lower frequency (1 kHz to 10 kHz) to ensure deep energy penetration and allow sufficient time for the heat to soak to the core.

- If your primary focus is maximum energy efficiency: Design the inductor for the tightest possible coupling that your process can safely accommodate to minimize energy loss to the surrounding environment.

- If you are heating a non-magnetic material like aluminum or copper: You must rely solely on the Joule effect, which may require higher power or more efficient coupling compared to heating steel.

By understanding these interconnected factors, you can move from simply using induction heating to truly engineering the process for your desired outcome.

Summary Table:

| Factor | Key Influence on Heating Process |

|---|---|

| Frequency | Controls heating depth (skin effect) |

| Power | Determines the rate of heating |

| Coil Design & Coupling | Shapes the heating pattern and affects efficiency |

| Material Resistivity | Higher resistivity materials heat faster |

| Magnetic Permeability | Intensifies heating in magnetic materials below the Curie point |

Ready to Optimize Your Induction Heating Process?

Understanding these factors is the first step. Implementing them effectively requires the right equipment and expertise. KINTEK specializes in high-performance lab equipment and consumables, including induction heating systems tailored for precise thermal processing in research and development.

Let our experts help you select the ideal system to achieve superior control, efficiency, and repeatability in your applications. Contact KINTEL today for a consultation and discover how our solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Non Consumable Vacuum Arc Induction Melting Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- Can you get an electrical arc in vacuum? How High Voltage Creates Plasma in a Void

- What is vacuum hot pressing? Achieve Maximum Density & Purity in Advanced Materials

- Is brazing or welding cheaper? A Detailed Cost Analysis for Your Project

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What is the effect of increasing the pressure during sintering? Achieve Maximum Density and Superior Performance