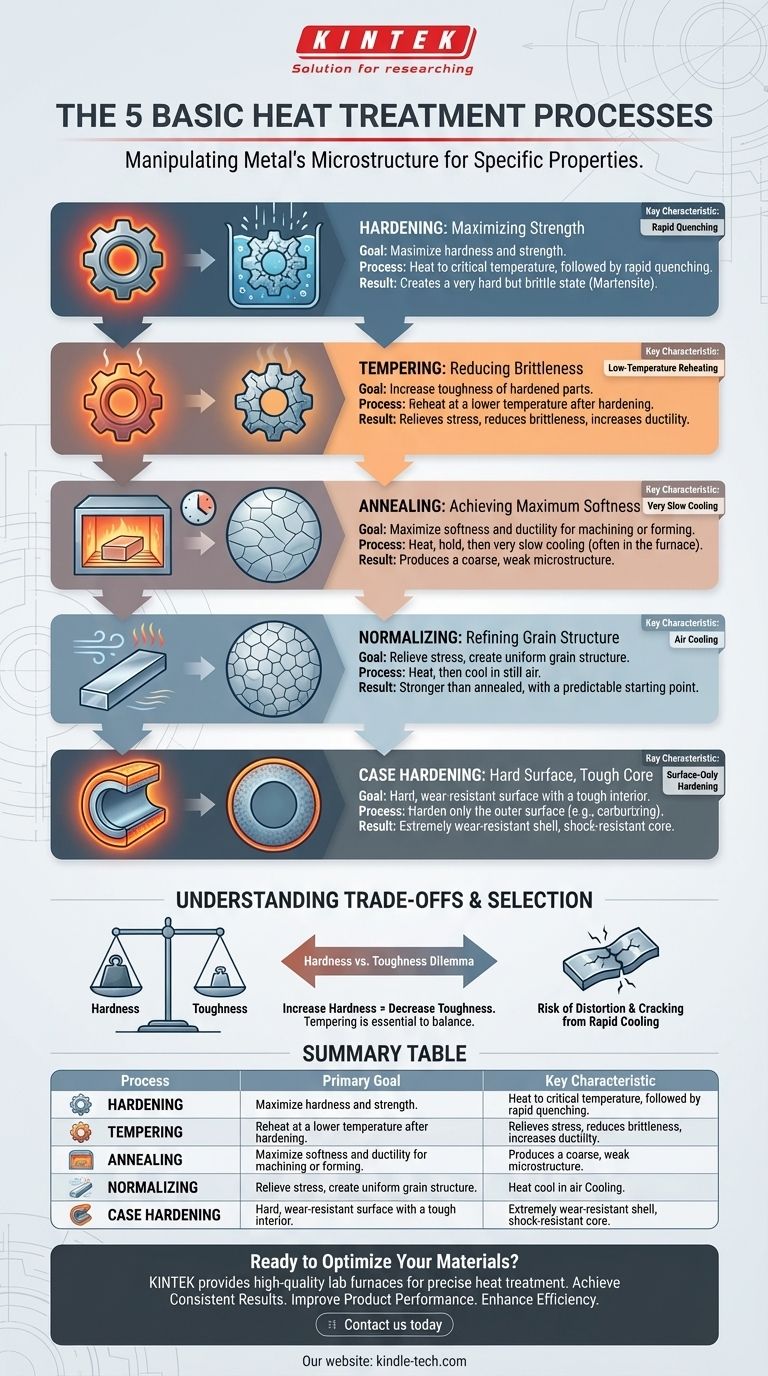

The five basic heat treatment processes are Hardening, Tempering, Annealing, Normalizing, and Case Hardening. Each process involves a specific cycle of heating and cooling designed to manipulate the internal structure of a metal, thereby achieving a distinct set of mechanical properties.

Heat treatment is not a single action but a set of controlled thermal processes. The core principle is that by precisely managing temperature and cooling rates, you can fundamentally change a metal's microstructure to achieve specific goals like increased hardness, improved toughness, or enhanced machinability.

The Purpose of Heat Treatment: Controlled Transformation

Heat treatment is the practice of altering a metal's physical and mechanical properties without changing its shape. It is a critical step in manufacturing that enables a single type of steel, for example, to be used for vastly different applications.

Manipulating the Microstructure

At a microscopic level, metals are composed of crystal structures or "grains." The size, shape, and composition of these grains determine properties like strength, ductility, and hardness.

Heating and cooling a metal allows these grains to dissolve and reform in controlled ways. This ability to manipulate the microstructure is the foundation of all heat treatment.

The Five Core Heat Treatment Processes

While there are many specialized variations, nearly all heat treatments are derived from these five fundamental processes.

Hardening: Maximizing Strength

The goal of hardening is to make a metal, typically steel, as hard and strong as possible.

The process involves heating the steel to a critical temperature where its internal structure transforms, followed by a rapid cooling process known as quenching. This rapid cooling traps the structure in a very hard but brittle state called martensite.

Tempering: Reducing Brittleness

Hardened parts are often too brittle for practical use. Tempering is a secondary process performed immediately after hardening to increase toughness.

The part is reheated to a much lower temperature, held for a specific time, and then cooled. This process relieves internal stresses and reduces some hardness, but it significantly increases the material's ductility and resistance to shock.

Annealing: Achieving Maximum Softness

Annealing is a process used to make a metal as soft and ductile as possible. This is often done to make a material easier to machine, stamp, or form.

It involves heating the metal, holding it at that temperature, and then allowing it to cool very slowly, often by leaving it inside the insulated furnace as it cools. This slow cooling produces a coarse and weak microstructure.

Normalizing: Refining Grain Structure

Normalizing is used to relieve internal stresses caused by processes like forging or welding and to create a more uniform and refined grain structure.

The process is similar to annealing, but the cooling is done faster by letting the part cool in still air. This results in a material that is stronger and harder than an annealed part but not as hard as a hardened one. It produces a predictable and consistent starting point for further manufacturing.

Case Hardening: A Hard Surface on a Tough Core

Case Hardening, also known as surface hardening, is a category of processes used to harden only the outer surface of a part while leaving the inner core soft and tough.

This creates a part with an extremely wear-resistant exterior shell and a shock-resistant interior. Common methods include carburizing, where carbon is diffused into the surface of low-carbon steel before the hardening process.

Understanding the Inherent Trade-offs

Choosing a heat treatment process requires understanding the balance between competing properties. No single process can maximize all desirable characteristics.

The Hardness vs. Toughness Dilemma

This is the most fundamental trade-off in heat treatment. As you increase a material's hardness (its resistance to scratching and indentation), you almost always decrease its toughness (its ability to absorb energy and resist fracturing).

The hardening process creates maximum hardness but also maximum brittleness. Tempering is the essential step to intentionally sacrifice some hardness to regain the necessary toughness for the application.

The Risk of Distortion and Cracking

The rapid temperature changes involved in heat treatment, especially the quenching step of hardening, induce significant internal stress.

This stress can cause parts to warp, distort, or even crack if not managed properly. The geometry of the part and the severity of the quench are critical factors.

Cost and Time Considerations

Processes that require very slow cooling, like annealing, tie up furnace time and can be costly.

Complex quenching setups and the secondary step of tempering also add to the overall cost and complexity of producing a finished part. The choice of process must be justified by the performance requirements of the component.

Selecting the Right Process for Your Goal

Your choice depends entirely on the final properties your component requires.

- If your primary focus is maximum wear resistance and strength: Start with Hardening, immediately followed by Tempering to achieve the desired toughness.

- If your primary focus is making a part easier to machine or form: Choose Annealing for the softest possible state.

- If your primary focus is relieving stress and ensuring material uniformity: Normalizing is the most effective and efficient choice.

- If your primary focus is a durable surface with a shock-resistant core: You need a Case Hardening process to create this dual property.

Ultimately, selecting the correct heat treatment is about matching the process to the engineering problem you need to solve.

Summary Table:

| Process | Primary Goal | Key Characteristic |

|---|---|---|

| Hardening | Maximize Strength & Hardness | Rapid Quenching |

| Tempering | Reduce Brittleness, Increase Toughness | Low-Temperature Reheating |

| Annealing | Maximize Softness & Ductility | Very Slow Cooling |

| Normalizing | Relieve Stress, Refine Grain Structure | Air Cooling |

| Case Hardening | Hard Surface, Tough Core | Surface-Only Hardening |

Ready to Optimize Your Materials with Precision Heat Treatment?

The right heat treatment process is critical for achieving the exact mechanical properties your components need. KINTEK specializes in providing the high-quality lab furnaces and equipment required for precise hardening, tempering, annealing, and more.

We help laboratories and manufacturers like you:

- Achieve Consistent Results with reliable, precise temperature control.

- Improve Product Performance by selecting and applying the optimal heat treatment cycle.

- Enhance Efficiency with durable equipment designed for your specific applications.

Contact us today using the form below to discuss your lab's needs. Our experts will help you select the perfect equipment to master the five basic processes and advance your material science projects.

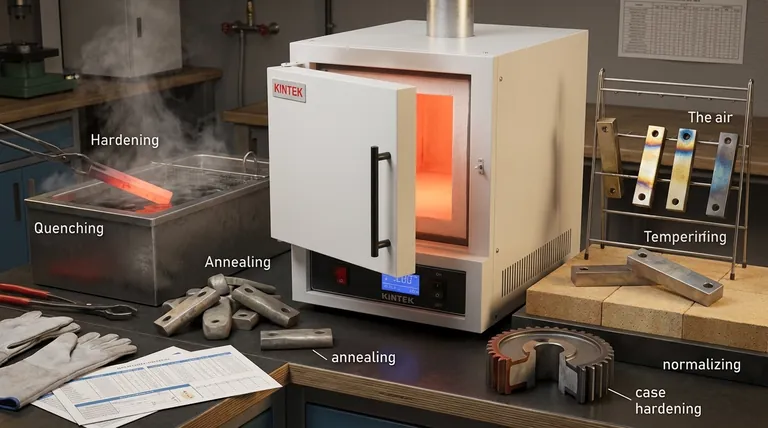

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace Tubular RTP Heating Furnace

- 1700℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- Does melting point ever change? Unlock the Secrets of Pressure and Purity

- What affects the melting point of a substance? Uncover the Key Factors & Forces

- What are the factors affecting the rate of melting process? Master Heat Transfer for Faster Results

- What is the debinding process? A Guide to Critical Binder Removal for MIM & 3D Printing

- What hazard is involved when using a furnace? Protect Your Home from the Silent Killer