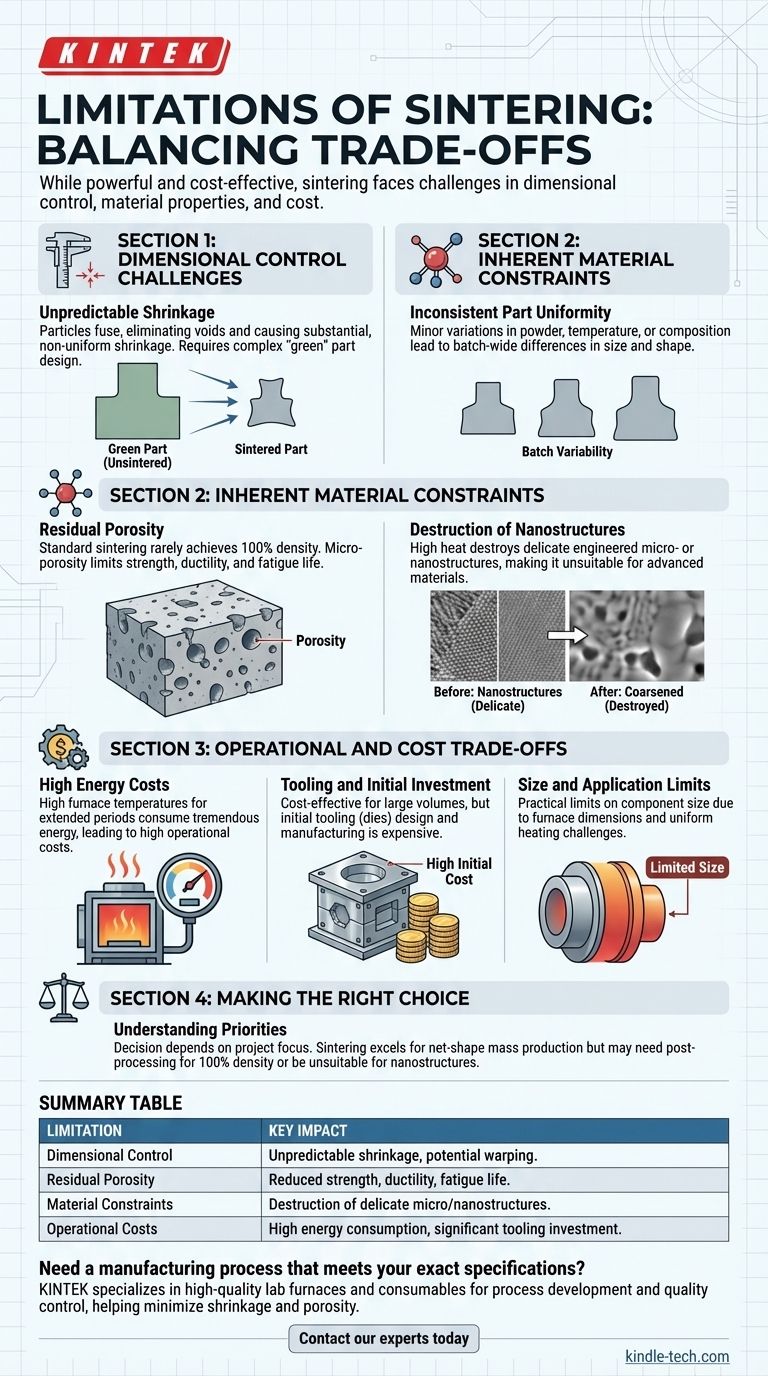

While a powerful and cost-effective process, the primary limitations of sintering are significant challenges in dimensional control due to material shrinkage, the inherent residual porosity in the final part, high energy consumption, and the destruction of delicate pre-existing micro- or nanostructures within the raw material. These factors must be carefully managed to achieve the desired component specifications.

Sintering excels at creating strong, complex parts at scale, but it is not a perfect densification process. Its core limitations arise from the fundamental trade-off between consolidating powder into a solid form and the resulting changes in dimension, internal structure, and cost.

The Challenge of Dimensional Control

One of the most significant engineering challenges in sintering is predicting and controlling the final dimensions of the part. This stems from the very nature of the process: turning loose powder into a dense solid.

Unpredictable Shrinkage

As particles fuse together during sintering, the voids between them are eliminated, causing the entire component to shrink. This shrinkage can be substantial and is not always perfectly uniform, which can warp the part or throw it out of tolerance.

Manufacturers must meticulously account for this shrinkage in the initial design of the "green" (unsintered) part, often requiring significant trial and error.

Inconsistent Part Uniformity

Achieving perfectly identical dimensions across a large batch of sintered parts is difficult. Minor variations in powder density, temperature distribution within the furnace, or material composition can lead to slight differences in the final size and shape of each component.

The Need for Process Tuning

Because of these variables, sintering often requires extensive empirical analysis and theoretical modeling to dial in the process. Reaching the required specifications demands a deep understanding of the interplay between material grain size, temperature, and pressure.

Inherent Material Constraints

Sintering fundamentally alters the material at a microscopic level. While this creates strength, it also introduces unavoidable constraints on the final product's properties.

Residual Porosity

Standard sintering rarely achieves 100% theoretical density. The final part almost always contains a certain amount of micro-porosity, which can act as a stress concentration point and may limit the material's ultimate strength, ductility, or fatigue life.

While processes like Hot Isostatic Pressing (HIP) can be added to reduce this porosity, it adds significant cost and complexity.

Destruction of Nanostructures

The high temperatures required for sintering will destroy or coarsen any delicate micro- or nanostructures that were engineered into the initial powder. This makes the process unsuitable for producing advanced materials that rely on the preservation of these fine features for their unique properties.

Operational and Cost Trade-offs

Beyond the physical limitations, sintering involves practical operational considerations that can make it the wrong choice for certain applications.

High Energy Costs

Heating industrial furnaces to the high temperatures needed for sintering—often for extended periods—consumes a tremendous amount of energy. This can lead to high operational costs, especially for materials with very high melting points.

Tooling and Initial Investment

While sintering is very cost-effective for large production volumes, the initial investment can be high. The dies and tooling required to press the initial powder into its green shape are expensive to design and manufacture.

Size and Application Limits

There are practical limits on the size of components that can be produced via sintering, constrained by furnace dimensions and the difficulty of achieving uniform heating in a very large part. Additionally, some material compositions are simply not suitable for the process, as seen with certain types of iron ore that cannot be fully charged into a blast furnace after sintering.

Making the Right Choice for Your Goal

Understanding these limitations is key to leveraging sintering effectively. The decision to use this process depends entirely on your project's specific priorities.

- If your primary focus is mass production of complex, net-shape parts: Sintering is an excellent choice, provided you can invest in the tooling and process control needed to manage dimensional shrinkage.

- If your primary focus is achieving absolute 100% density for maximum fatigue life: Standard sintering is likely insufficient; you will need to consider post-processing or alternative manufacturing methods.

- If your primary focus is preserving delicate material nanostructures: Sintering is fundamentally incompatible with this goal, as the high heat will alter the material's internal structure.

By acknowledging its inherent trade-offs, you can determine if sintering is the optimal path for manufacturing your component.

Summary Table:

| Limitation | Key Impact |

|---|---|

| Dimensional Control | Unpredictable shrinkage and potential warping of parts. |

| Residual Porosity | Reduced ultimate strength, ductility, and fatigue life. |

| Material Constraints | Destruction of delicate pre-existing micro- or nanostructures. |

| Operational Costs | High energy consumption and significant initial tooling investment. |

Need a manufacturing process that meets your exact specifications?

While sintering has its limitations, choosing the right lab equipment is crucial for process development and quality control. KINTEK specializes in providing high-quality lab furnaces and consumables that help you accurately test and optimize sintering parameters, minimizing shrinkage and porosity issues.

Contact our experts today to discuss how our reliable laboratory solutions can support your R&D and production goals, ensuring you select the best manufacturing path for your materials.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Spark Plasma Sintering Furnace SPS Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability